Segmentation iron core and coiling method for motor

A kind of iron core, winding technology, is used in the field of stator in the transmission permanent magnet synchronous motor, which can solve problems such as affecting the fullness of the slot, the coil sliding phenomenon, and the unable to be completely arranged. The effect of slot fullness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

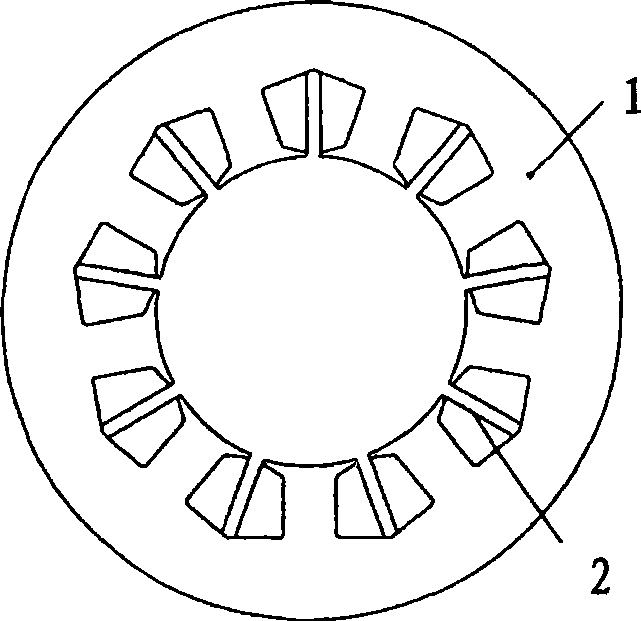

[0019] Such as figure 1 As shown, in the centralized winding motor where the winding is directly performed at the position of the tooth part 1 of the existing motor, since the stator core is an integral structure, a space 2 should be reserved during the winding process of the motor. Since this space cannot be used, the affect the motor efficiency.

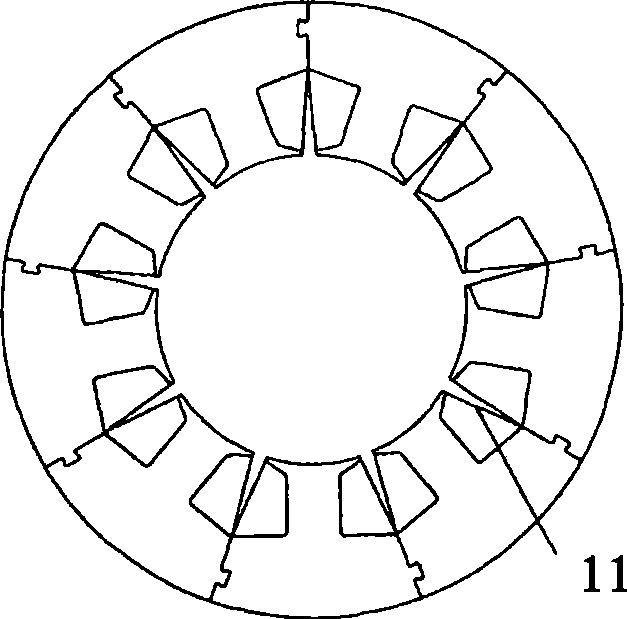

[0020] Figure 2A It shows the schematic diagram of the existing split iron core. At present, there are the following problems: a certain distance is reserved between adjacent teeth at the slot structure. At this time, due to the insulation distance of the opening, a part of the slot space 11 cannot be wound around. Wire.

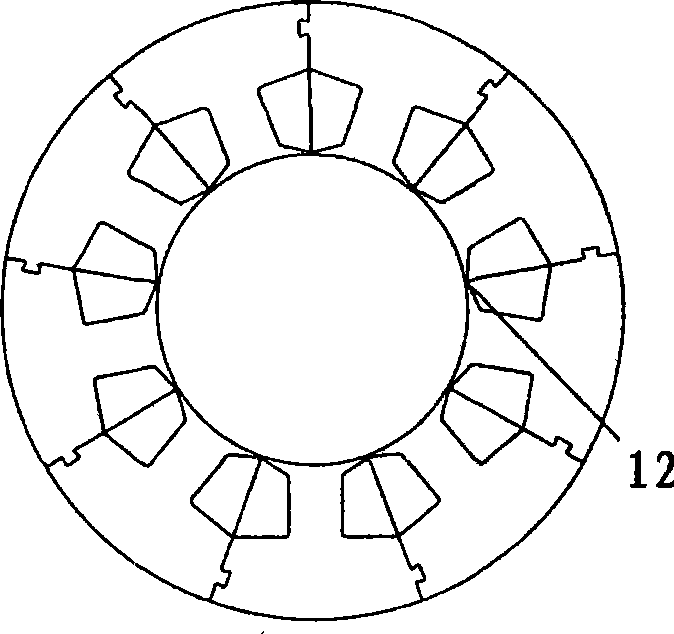

[0021] Figure 2B It shows another schematic diagram of the existing split iron core. At present, there are the following problems: due to the contact between adjacent teeth, part of the stator and rotor magnetic flux passes through the contact part 12 to form a closed loop without connecting with the stator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com