Cleaner for CMP equipment grinding head

A technology for cleaning devices and grinding heads, which is applied in the direction of grinding devices, grinding/polishing safety devices, grinding machine tools, etc., and can solve the threat of surface flatness and state of silicon wafer products, affecting the yield of silicon wafer products, micro-scratches, etc. problems, to achieve the effect of reducing the possibility of excessive particles and product scratches, reducing the time and frequency of maintenance and cleaning, and preventing crystallization and agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

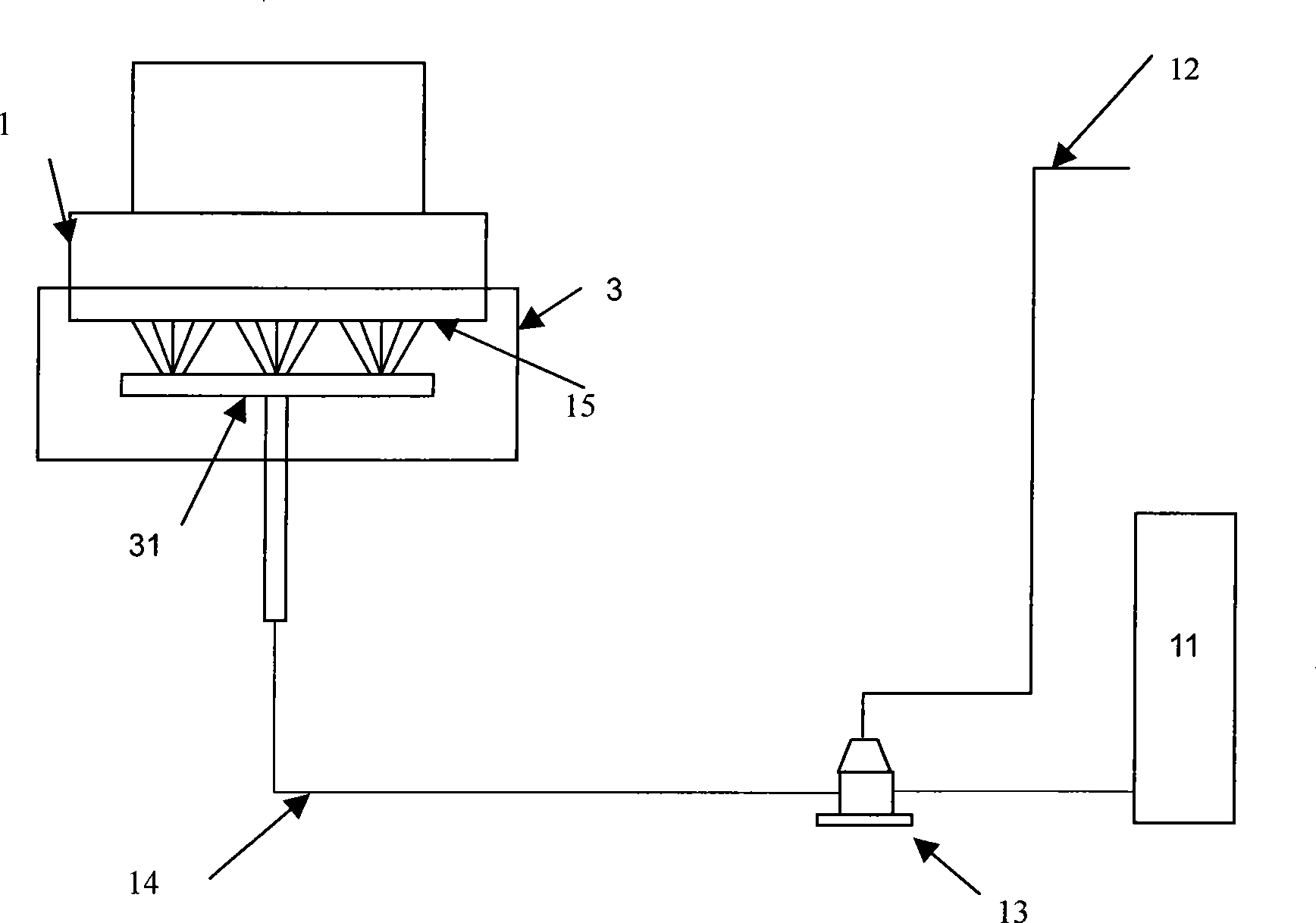

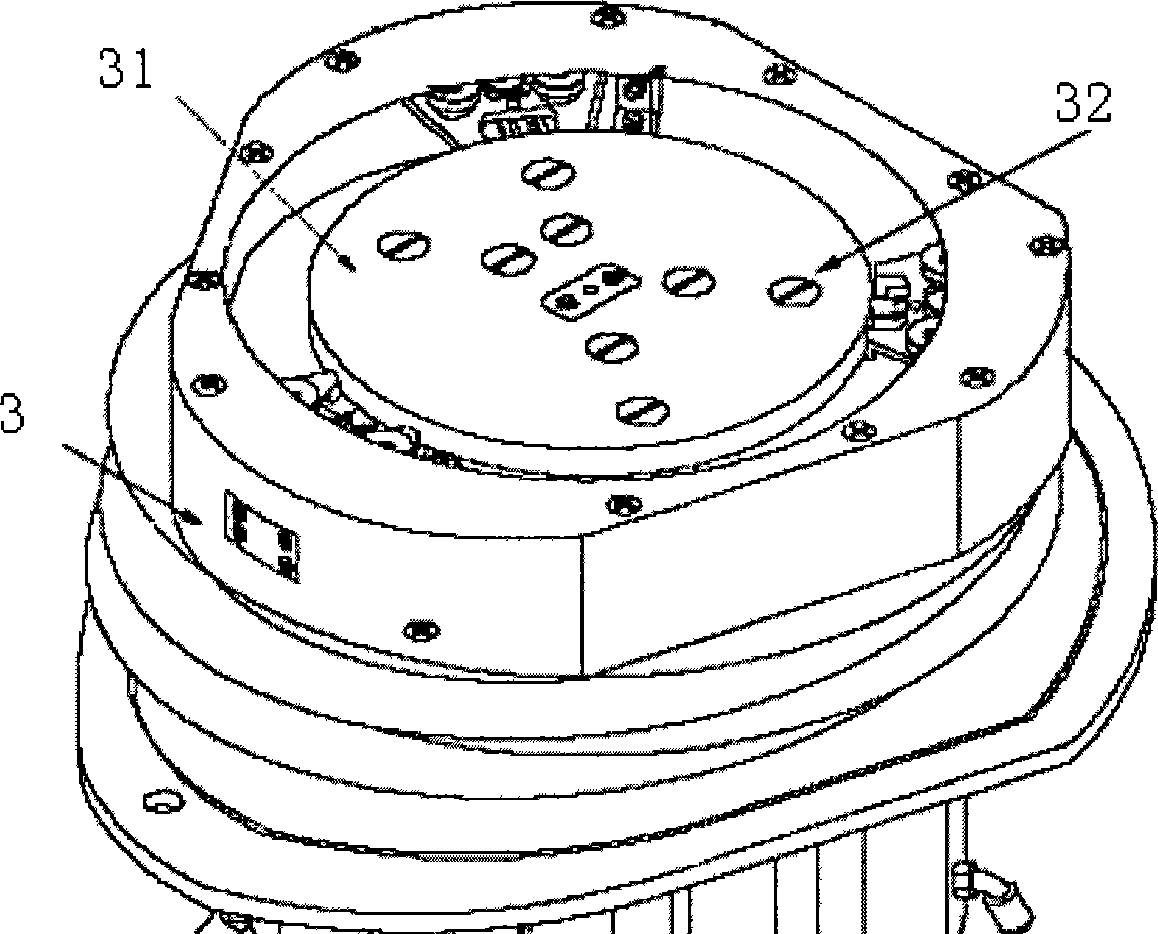

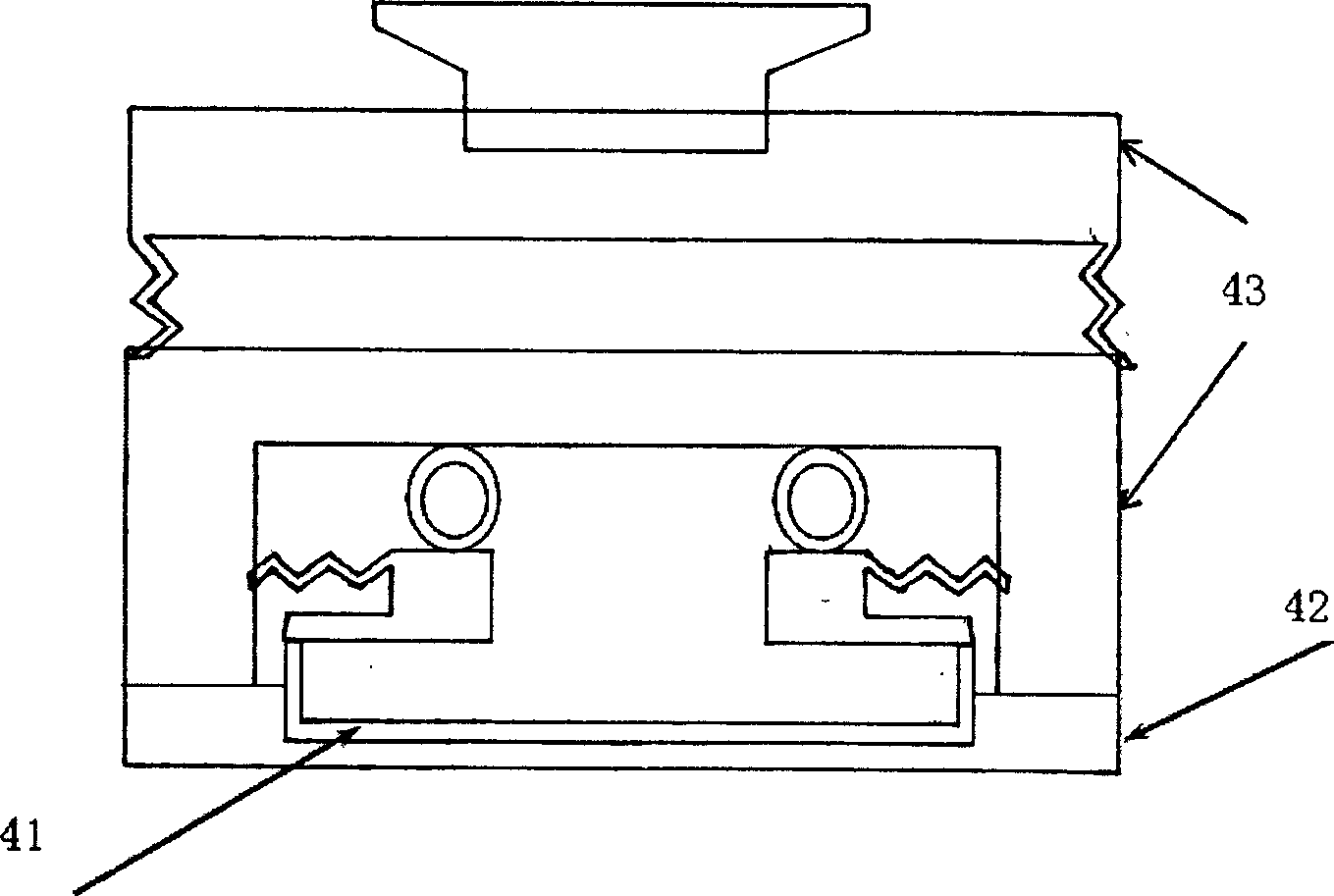

[0014] One embodiment of the CMP equipment grinding head cleaning device of the present invention is as follows: Figure 4 As shown, it includes a water supply module 11, a grinding head cleaning control air circuit 12, a pneumatic water valve 13, a water supply pipe 14 for the loading platform, and a grinding head loading and unloading device 3. The grinding head loading and unloading device 3 is as follows figure 2 As shown, the inner bottom of the device is a silicon chip carrier platform 31, and eight pure water nozzles 32 are distributed on the carrier platform 31, and the pure water nozzles are connected with the carrier platform water supply pipe 14; it also includes a pneumatic water valve 223 and a peripheral cleaning water supply pipe 24 One end of the peripheral cleaning water supply pipe 24 is a peripheral cleaning nozzle, and the grinding head cleaning control air circuit 12 simultaneously controls the opening and closing of the pneumatic water valve one 13 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com