Method and equipment for eliminating iron scraps from raw materials

A technology of iron filings and raw materials, applied in the field of magnetic separation, can solve the problems of reduced iron removal efficiency, increased chance of scraping, and long iron removal time, so as to reduce iron removal time, weaken grinding degree, and improve iron absorption effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

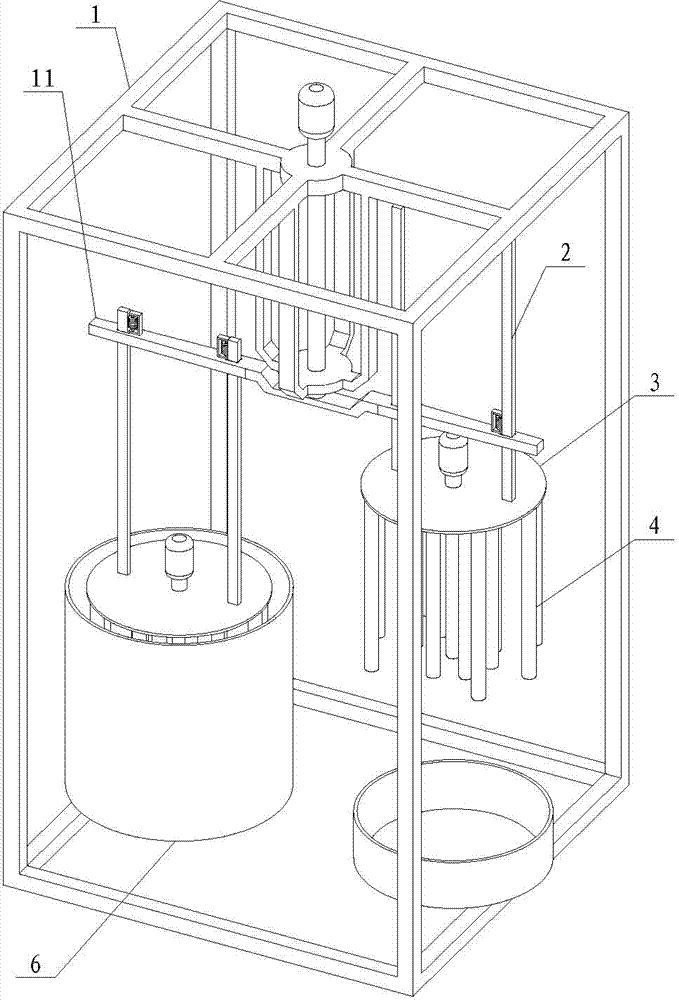

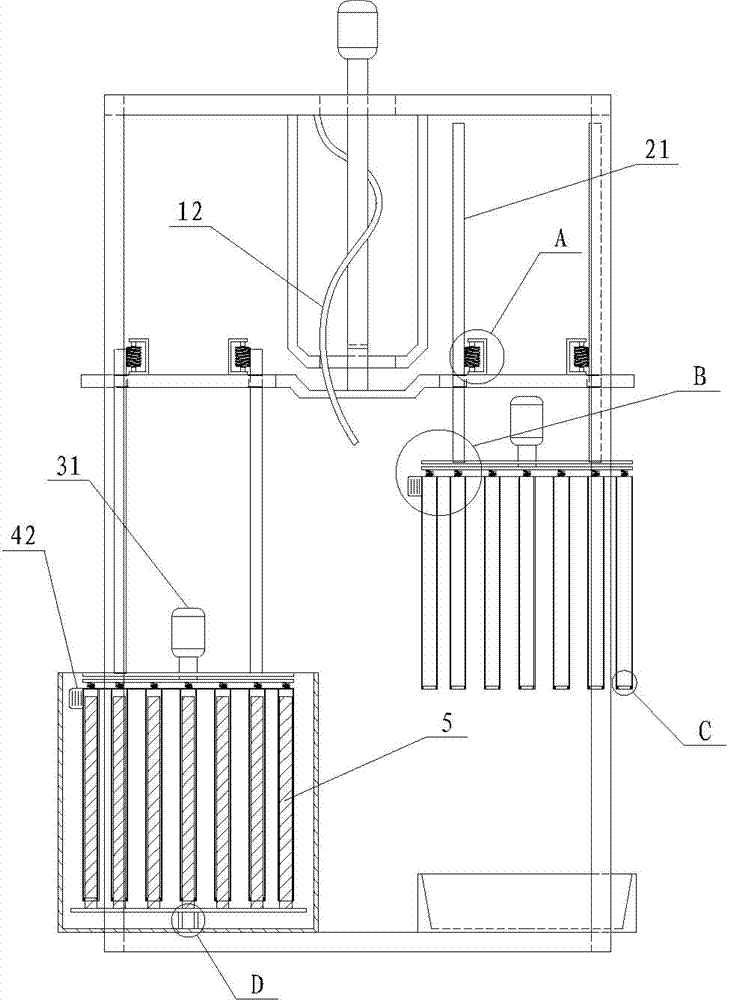

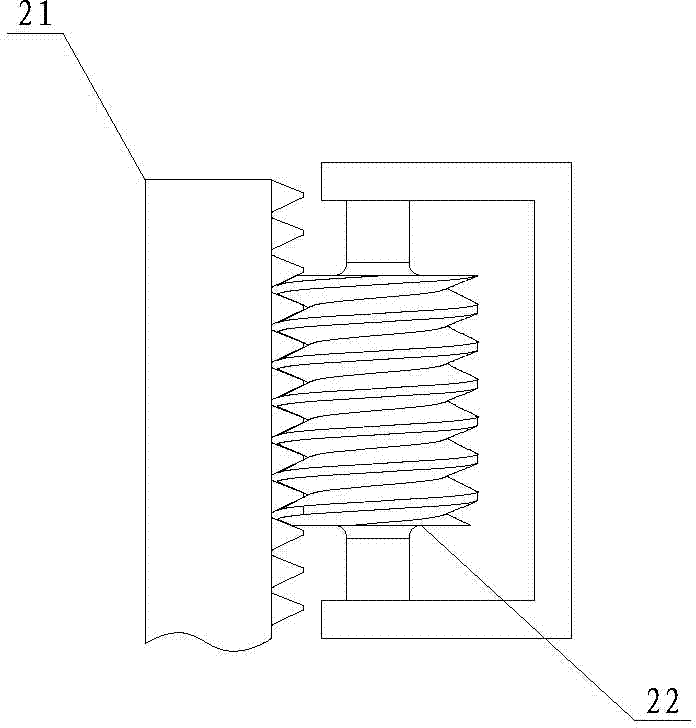

[0042] like Figures 1 to 6 As shown, a device for removing iron filings from raw materials includes a frame 1, a barrel 6, a group of magnetic rods 5 arranged in the barrel 6, a rotating arm 11 is arranged on the frame 1, and the rotating arm 11 can wind around the machine Frame 1 rotates horizontally; Lifting mechanism 2 is all set on each pivoting arm 11. The lifting mechanism 2 includes a rack 21 and a worm wheel 22 , the worm wheel 22 is arranged on the rotating arm 11 , the rack 21 meshes with the worm wheel 22 , and the lower end of the rack 21 is connected with the rotating mechanism 3 .

[0043] Motor 31, rotating disk 32 and spring 33 are set in rotating mechanism 3, and rotating disk 32 links to each other with motor 31; Spring 33 is fixed between connecting plate 41 and rotating disk 32, vibrator 42 is installed on connecting plate 41.

[0044] The iron cylinder group 4 is connected below the rotating mechanism 3, and the iron cylinder group 4 is provided with a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com