Special circumference weld opening/closing machine capable of tracking welding position automatically

A welding position and automatic tracking technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of difficult operator picking, unsuitable operation, easy to scratch the appearance of products, etc., to improve work efficiency. Efficiency and product quality, the effect of reducing the chance of scraping, and reducing the pickup process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

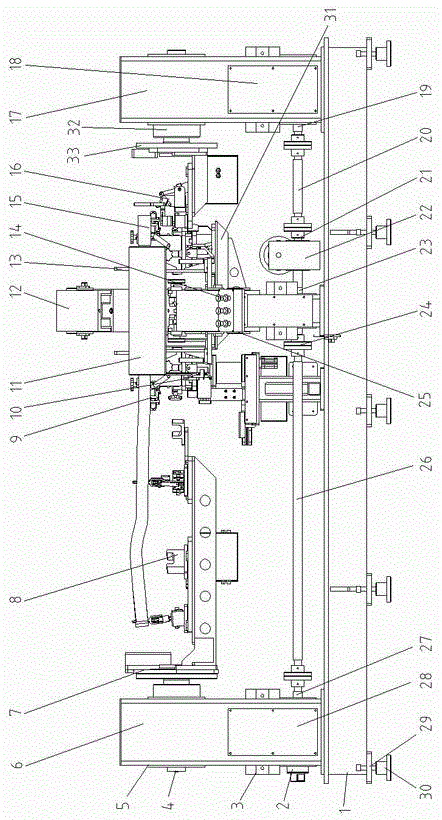

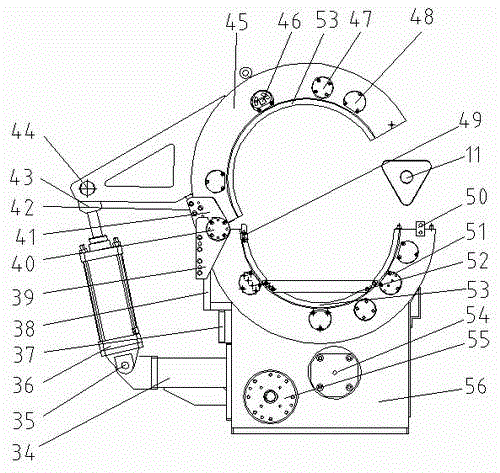

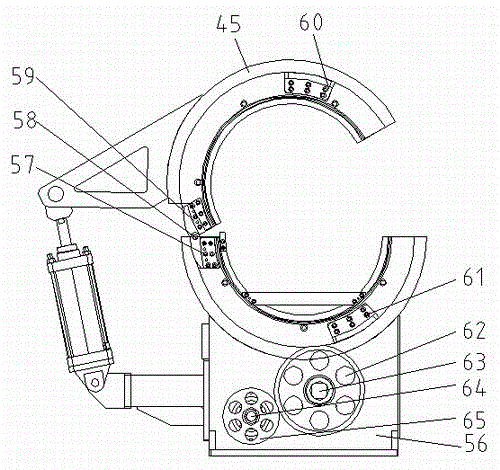

[0012] figure 1 , 2 , 3 shows a structural diagram of a ring welding opening and closing machine that automatically tracks the welding position.

[0013] In the figure, the automatic tracking welding position ring welding opening and closing special machine includes a base 1, a left box body 6, an air outlet fixture 8, a muffler fixture 10, a middle opening and closing box body 12, a fixed welding torch 15, an air inlet fixture 16, and a right box Body 17 and motor 22. The left end of the base 1 is fixed with a left box body 6, and the right end is fixed with a right box body 17. Flange bearing blocks 5 are arranged on the left and right sides of the left box body 6 top, and a main shaft 4 is movably adorned in the seat, and the left box body 6 bottom is Intermediate gear shaft fixing seat 3 and encoder seat 2 are installed on the left and right sides.

[0014] A middle opening and closing box body 12 is fixed in the middle right section of the base 1, and the cylinder supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com