High-frequency vertical spring probe card structure

A vertical, probe card technology, applied in the field of probe structure, can solve the problems of imprecise production, high cost, inability to reach the probe, save time and cost, reduce signal interference, and quickly generate the process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

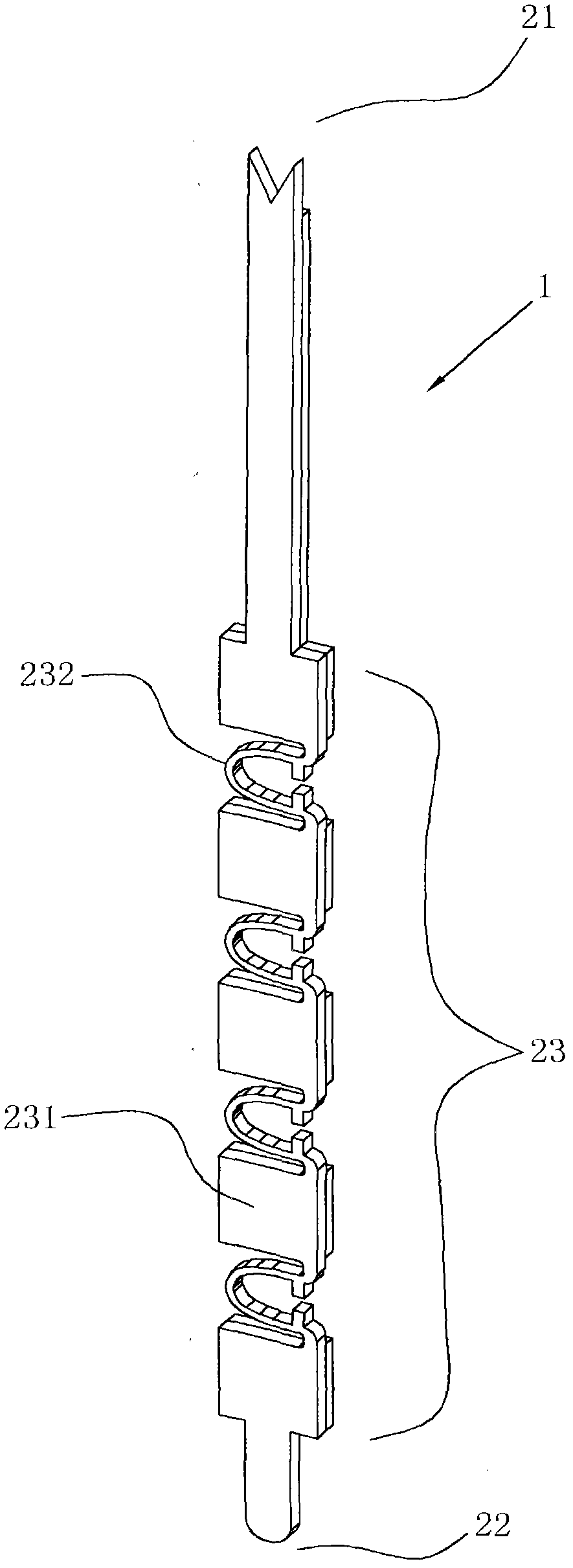

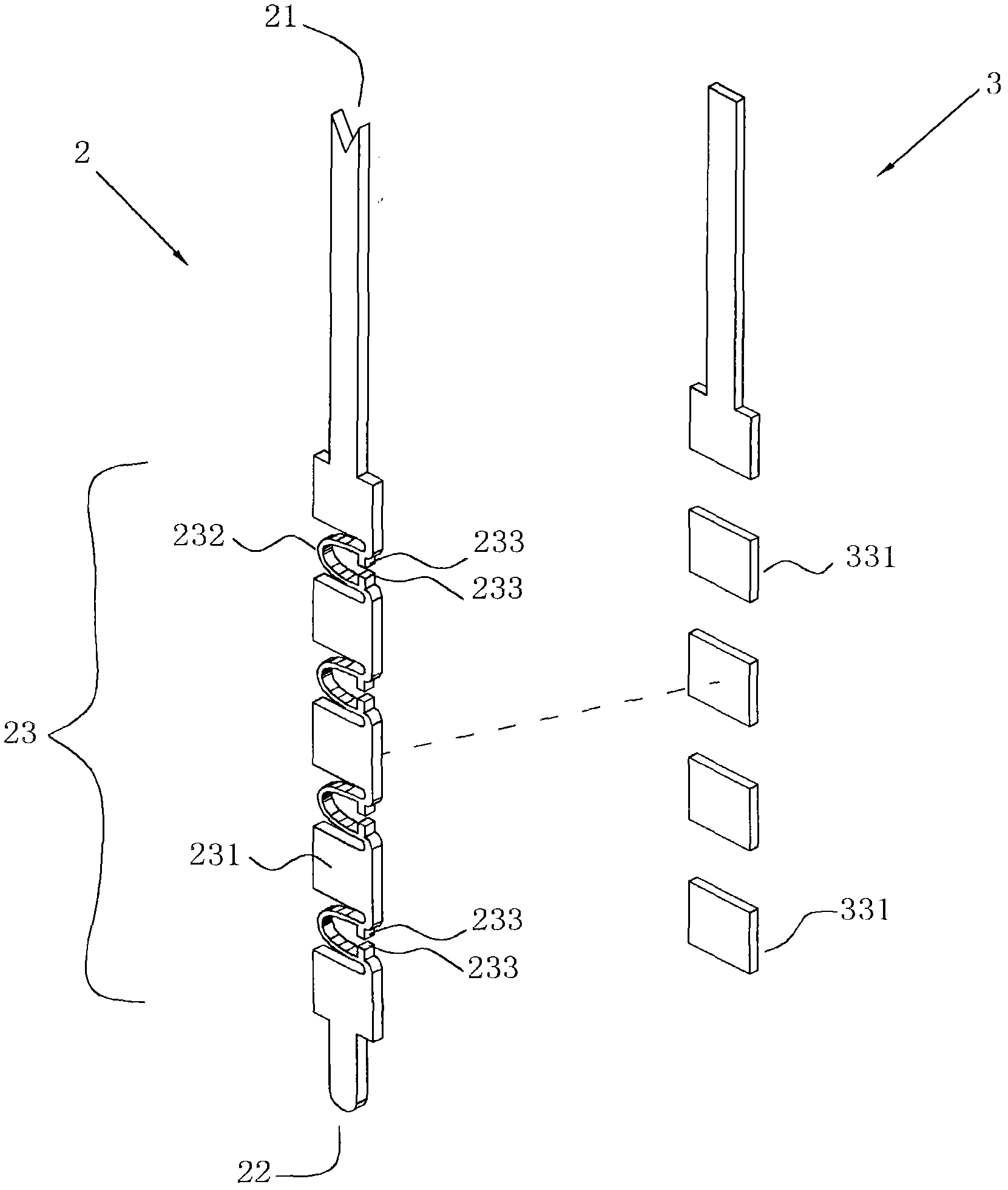

[0046] Please refer to figure 2 , figure 2 It is a combined schematic diagram of the structure of the first embodiment of the present invention. The probe 1 of the present invention has a first contact piece 21, a second contact piece 22 and a probe body 23, and the first contact piece 21 and the second contact piece 22 are used for electrical contact with an external member during pressure. Contact point; the probe body 23 has a plurality of plates 231 and a plurality of elastic bodies 232, which are interconnected and formed. The plurality of plates 231 are used to support the elasticity of the elastic body 232 when it is compressed in the vertical direction. variable. In addition, the flat design of the probes 1 is arranged in parallel, and the plane of the arrangement is the side of the probes (that is, the surface with a smaller surface area of the probes). Through the neat parallel arrangement, the same area of the component or circuit board to be tested can be t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com