A kind of preparation method of iron silicon nickel magnetic powder core

A technology of iron-silicon-nickel and magnetic powder cores, which is applied in the field of preparation of iron-silicon-nickel magnetic powder cores, can solve the problems that magnetic powder cores are difficult to meet the requirements of low cost and high performance, and achieve excellent saturation magnetic induction, low power loss, and high quality factor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

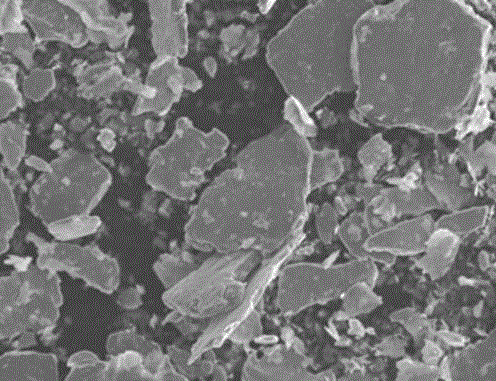

[0028]Put the iron-silicon-nickel powder (containing Si 5%, Ni 20%, Al 0.01%, Ca 0.05%, C 0.02%, and the balance is Fe) prepared by dry grinding process in a heat treatment furnace with a nitrogen protective atmosphere for annealing The annealing temperature was 700 °C and the annealing time was 1 h. The iron-silicon-nickel powder after annealing is proportioned according to the following particle size: -100 mesh to +200 mesh particles account for 30% of the total; -200 mesh to +300 mesh particles account for 40% of the total; -300 mesh to +400 mesh Purpose particles account for 20% of the total; the rest are -400 mesh particles, accounting for 10% of the total. Add phosphoric acid accounting for 1.8% of the mass of the iron silicon nickel powder to the prepared iron silicon nickel powder for passivation treatment, then add magnetic powder glue acetone solution accounting for 0.5% of the mass of the iron silicon nickel powder, and 0.8% of the mass of the iron silicon nickel po...

Embodiment 2

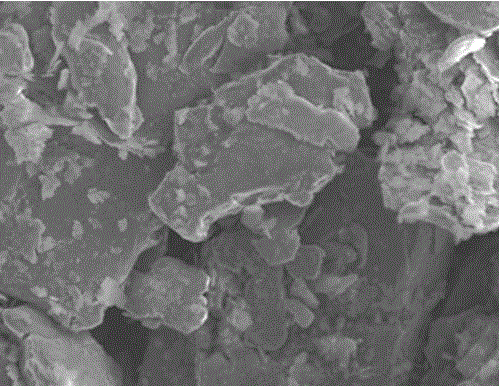

[0033] The FeSiNi powder (containing 10% Si, 15% Ni, 0.2% Al, 0.01% Ca, 0.05% C, and the balance is Fe) prepared by dry grinding process is placed in a heat treatment furnace with a nitrogen protective atmosphere for annealing The annealing temperature was 400 °C and the annealing time was 5 h. The iron-silicon-nickel powder after annealing is proportioned according to the following particle size: -100 mesh to +200 mesh particles account for 10% of the total; -200 mesh to +300 mesh particles account for 35% of the total; -300 mesh to +400 mesh Purpose particles accounted for 35% of the total; the remaining -400 mesh particles accounted for 20% of the total. Divide the prepared ferrosilicon nickel powder into 5 parts on average, numbered 1~5, add chromic acid accounting for 0.2%, 0.6%, 1.0%, 1.4% and 1.8% of the mass of the ferrosilicon nickel powder for passivation treatment, and then add Acetone solution of magnetic powder glue accounting for 1.0% of the mass of sendustrine ...

Embodiment 3

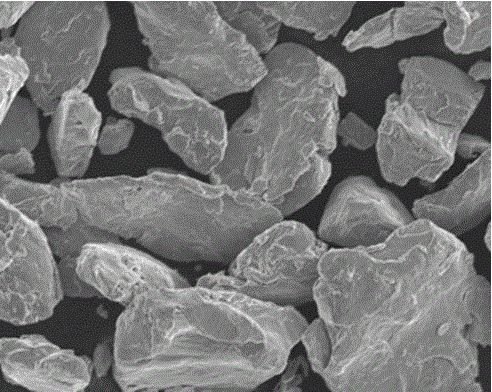

[0038] Put the ferrosilicon nickel powder (containing 20% Si, 8% Ni, 0.05% Al, 0.2% Ca, 0.02% C, and the balance is Fe) prepared by the wet grinding process in a heat treatment furnace with a nitrogen protective atmosphere for annealing The annealing temperature was 500 °C and the annealing time was 3 h. The iron-silicon-nickel powder after annealing is proportioned according to the following particle size: -100 mesh to +200 mesh particles account for 20% of the total; -200 mesh to +300 mesh particles account for 50% of the total; -300 mesh to +400 mesh Purpose particles accounted for 15% of the total; the remaining -400 mesh particles accounted for 15% of the total. Add hydrogen peroxide accounting for 0.2% of the mass of iron silicon nickel powder to the prepared iron silicon nickel powder for passivation treatment, then add magnetic powder glue acetone solution accounting for 1.5% of the mass of iron silicon nickel powder, and 0.02% of the mass of iron silicon nickel powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| saturation magnetic induction | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com