Assembled stacked inductor device

A stacked inductor and assembled technology, which is applied in the direction of transformer/inductor magnetic core, transformer/inductor parts, circuits, etc., can solve the problems of increasing inductance, unable to meet electrical requirements, and low inductance. Achieve the effect of good inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

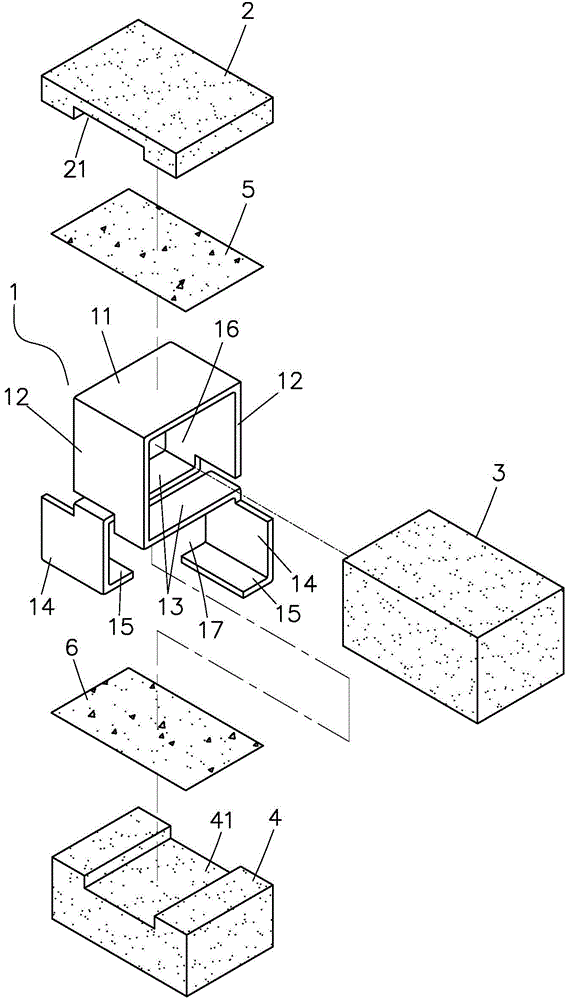

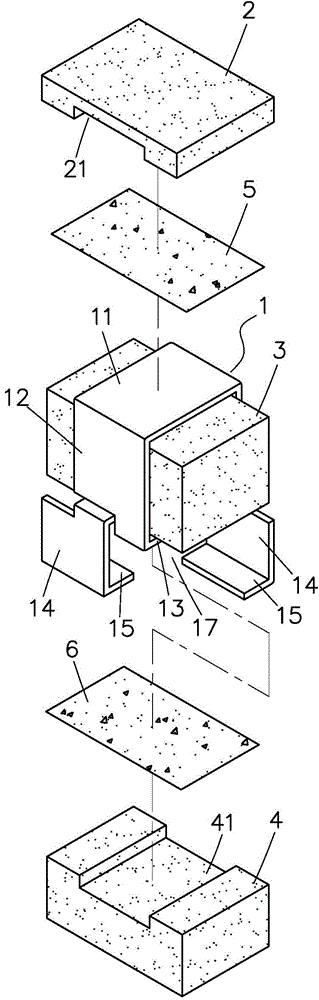

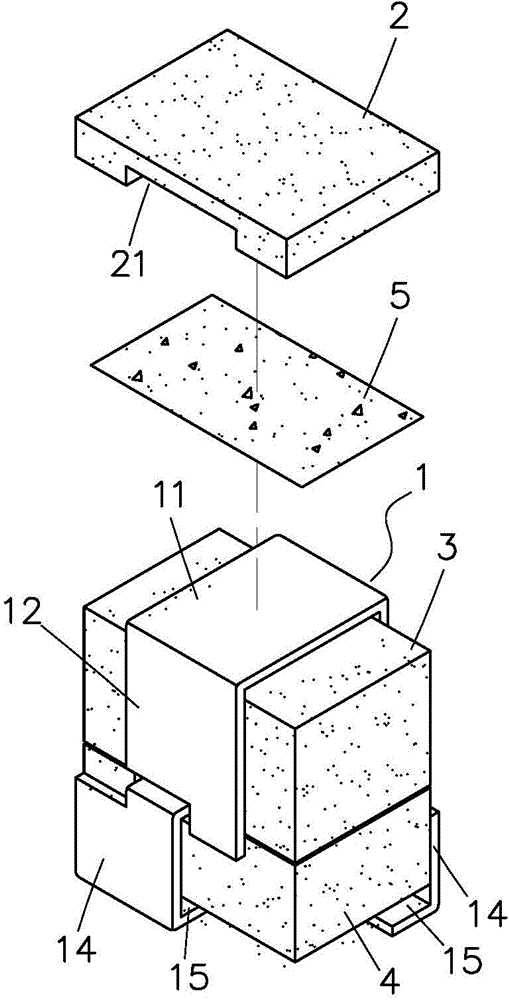

[0033] refer to figure 1 As shown, the assembled laminated inductor device of the present invention includes an approximately 8-shaped metal sheet coil 1 formed by stamping, three iron core bodies 2, 3, 4 and two sheet bodies 5, upper, middle, and lower. 6.

[0034] The above-mentioned approximately 8-shaped metal sheet coil 1 is generally made of copper sheet by stamping, and of course it does not exclude the use of other types of electrical conductor materials. The ends of the two vertical surfaces 12 are staggered and then bent inwardly to form a lower plane 13, and the ends of the lower plane 13 are respectively bent downwards to form upright electrical conductive pins 14 and bent legs 15 at the ends.

[0035] The stamping structure of the approximate 8-shaped sheet metal coil 1 forms a multi-layered coil mechanism with an approximate 8-shaped shape and an upper-layer accommodating space 16 and a lower-layer accommodating space 17 .

[0036] The upper iron core body 2, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com