Preparation method of metal powder for nanocrystalline magnetic core

A metal powder and nanocrystalline technology, which is applied in the field of preparation of metal powder for nanocrystalline magnetic cores, can solve the problems of high price, general DC bias ability, and difficult application, and achieve low production costs, improve DC bias ability, The effect of a high quality factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] A method for preparing a high-performance nanocrystalline magnetic powder core, comprising the steps of:

[0017] 1) Heat-treat the iron-based amorphous ribbons prepared by the rapid cooling method to transform them into nanocrystalline ribbons; wherein, the mass percentage of the iron-based amorphous ribbons is: 3-15% Ni, 1-10% Si, 1~4%B, 1~9%Al, the balance is Fe;

[0018] 2) crushing the nanocrystalline thin ribbon to obtain nanocrystalline metal powder;

[0019] 3) performing ball milling on the nanocrystalline metal powder;

[0020] 4) Screen the nanocrystalline metal powder, and then mix it into a powder consisting of 90% to 98% of the first powder passing through -200 mesh and 2% to 10% of the second powder passing through -150 to +200 mesh Powder particle distribution;

[0021] 5) Mixing the mixed nanocrystalline metal powder with an adhesive to form a magnetic core by pressing; and annealing the formed magnetic core, and then coating the magnetic core with a...

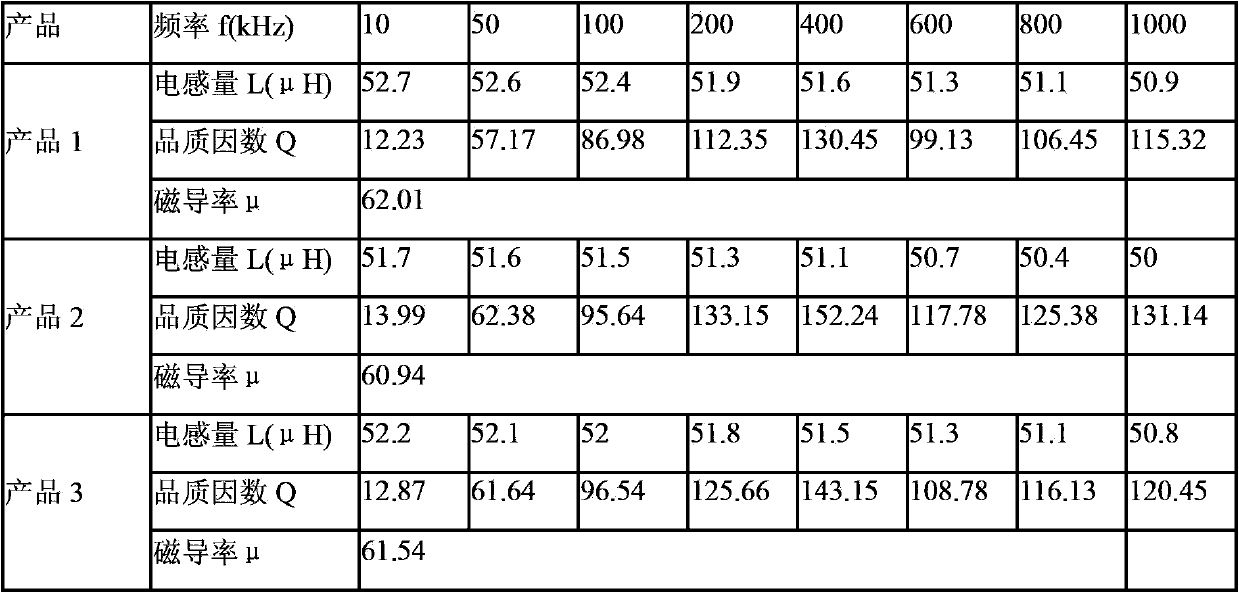

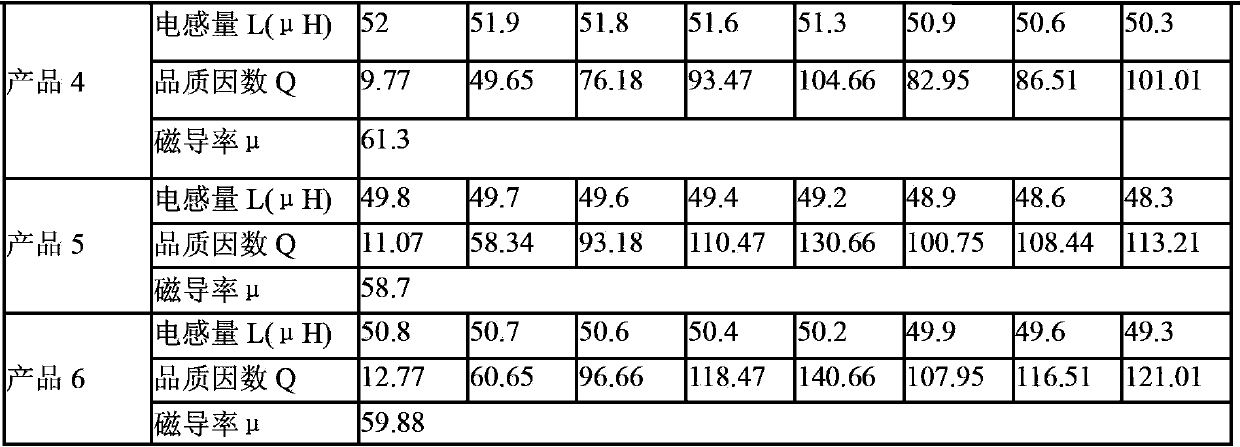

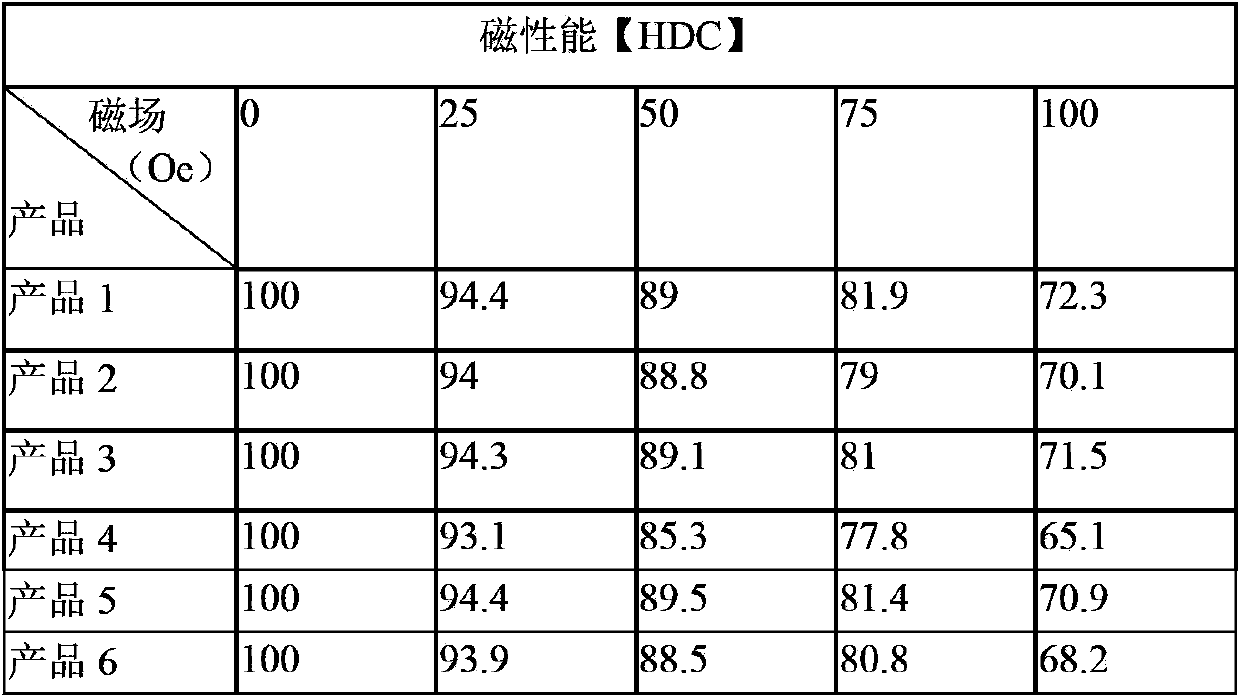

example 1

[0024] The iron-based amorphous thin strips prepared by the rapid cooling method were heat-treated in an inert gas at 580° C. for 1 hour to obtain nanocrystalline thin strips; they were broken and shaped; 90% of the first powder of -200 mesh was selected and 10% of the second powder of -150~+200 mesh, mixed with 5wt‰ sodium silicate, through compression molding, select the magnetic core for annealing, and at the same time pass nitrogen into the heat treatment furnace, the temperature is 500 ° C, the time is 2 hours, and finally The surface of the magnetic powder core is coated with epoxy resin paint. The nanocrystalline magnetic powder core product 1 with the specifications of Φ26.9 / Φ14.7×11.2 (that is, the outer diameter is 26.9mm, the inner diameter is 14.7mm, and the height is 11.2mm) is obtained.

example 2

[0026] Heat-treat the iron-based amorphous thin strips prepared by the rapid cooling method in an inert gas at 620° C. for 1 hour to obtain nanocrystalline thin strips; crush and shape them; select 90% of the first powder of -200 mesh and 10% of the second powder of -150~+200 mesh, mixed with 5wt‰ sodium silicate, through compression molding, select the magnetic core for annealing, and at the same time pass nitrogen into the heat treatment furnace, the temperature is 500 ° C, the time is 2 hours, and finally The surface of the magnetic powder core is coated with epoxy resin paint. The nanocrystalline magnetic powder core product 2 with specifications of Φ26.9 / Φ14.7×11.2 (that is, outer diameter 26.9mm, inner diameter 14.7mm, height 11.2mm) was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com