Thin film inductor and power supply conversion circuit

A thin-film and inductive technology, applied in circuits, output power conversion devices, transformer/inductor components, etc., can solve the problems of current surge, burnt devices, and inductance reduction in circuit conversion circuits, reducing circulation and reducing magnetic flux. resistance, reducing the effect of easy saturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0139] Figure 9 is a schematic flowchart of a method 400 for manufacturing a thin film inductor according to an embodiment of the present invention. Such as Figure 9 As shown, the preparation method 400 includes:

[0140] S410, configuring the first thin film magnetic core 210;

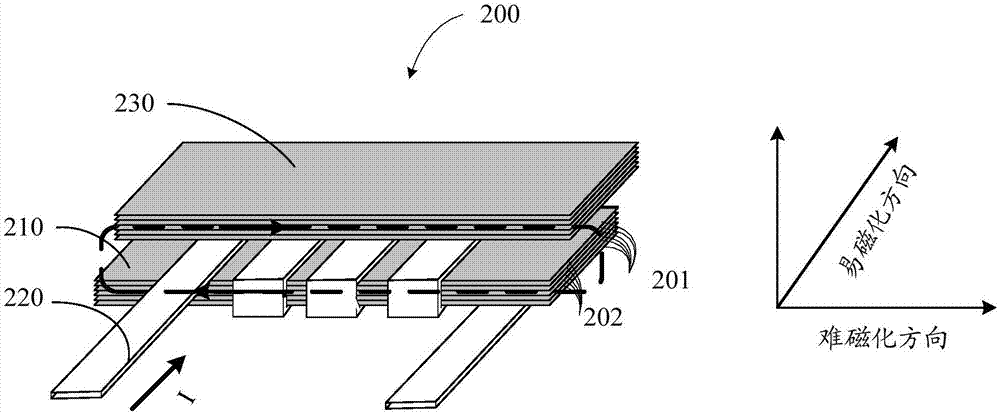

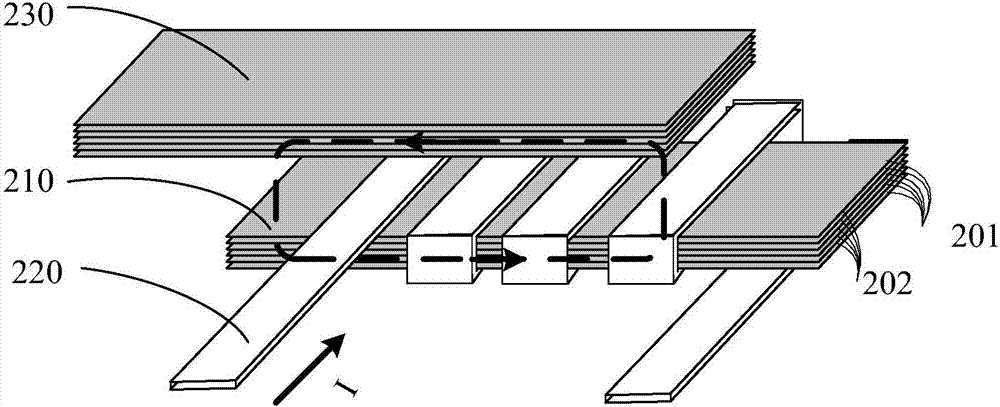

[0141] S420, wind at least one winding on the first thin film magnetic core 210 along the hard magnetization direction of the first thin film magnetic core 210, wherein the projection of the at least one winding 220 on the first plane surrounds the first thin film magnetic core The projection of the core on the first plane, the first plane is perpendicular to the hard magnetization direction of the first thin film magnetic core 210;

[0142] S430, configuring at least one second thin film magnetic core 230, the at least one second thin film magnetic core 230 is not wound with a winding, and each second thin film magnetic core 230 in the at least one second thin film magnetic core 230 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com