Yellowing-resistant high-transmittance invisible car cover and preparation method thereof

A technology of anti-yellowing and car coating, which is applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of not meeting the requirements of anti-yellowing of invisible car coatings, poor compatibility and dispersion, and reduced coating transparency. Achieve good mechanical properties, system stability, and increase crosslinking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] In a second aspect, the present invention also provides a method for preparing the above-mentioned anti-yellowing high-transparency invisible car covering, comprising the following steps:

[0029] S01, weigh polycarbonate diol, isocyanate, chain extender and solvent in expected mass fractions in a container, stir and disperse for a period of time at room temperature;

[0030] S02, add the leveling agent and the catalyst of expected mass fraction in turn, continue to stir and disperse at room temperature for a period of time, and obtain the polyurethane coating;

[0031] S03, the obtained polyurethane coating is coated on the TPU transparent film by a coating machine, baked and aged to obtain the invisible car cover.

[0032] Further, in step S01 and step S02, the rotating speed of stirring and dispersing is 450rpm-800rpm, and the time of stirring and dispersing is 15min-30min. In step S03, the baking temperature is 95°C-120°C, and the time is 3min-8min; the aging tempe...

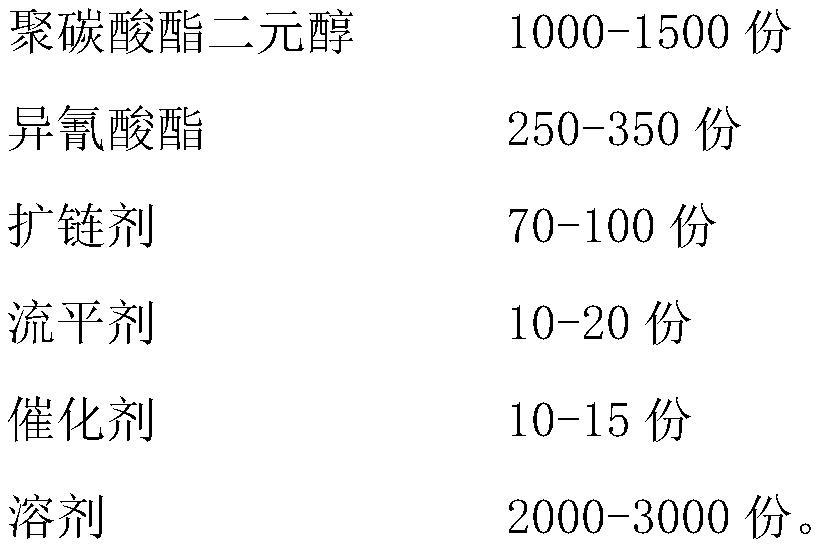

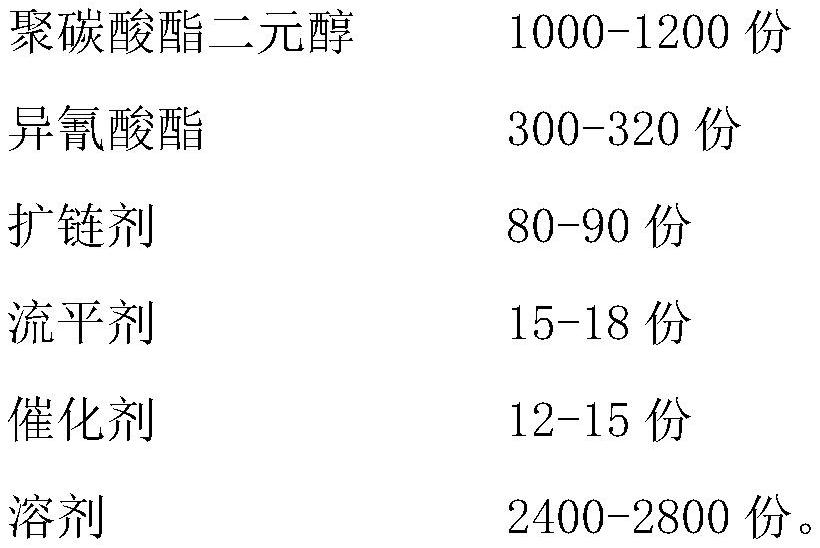

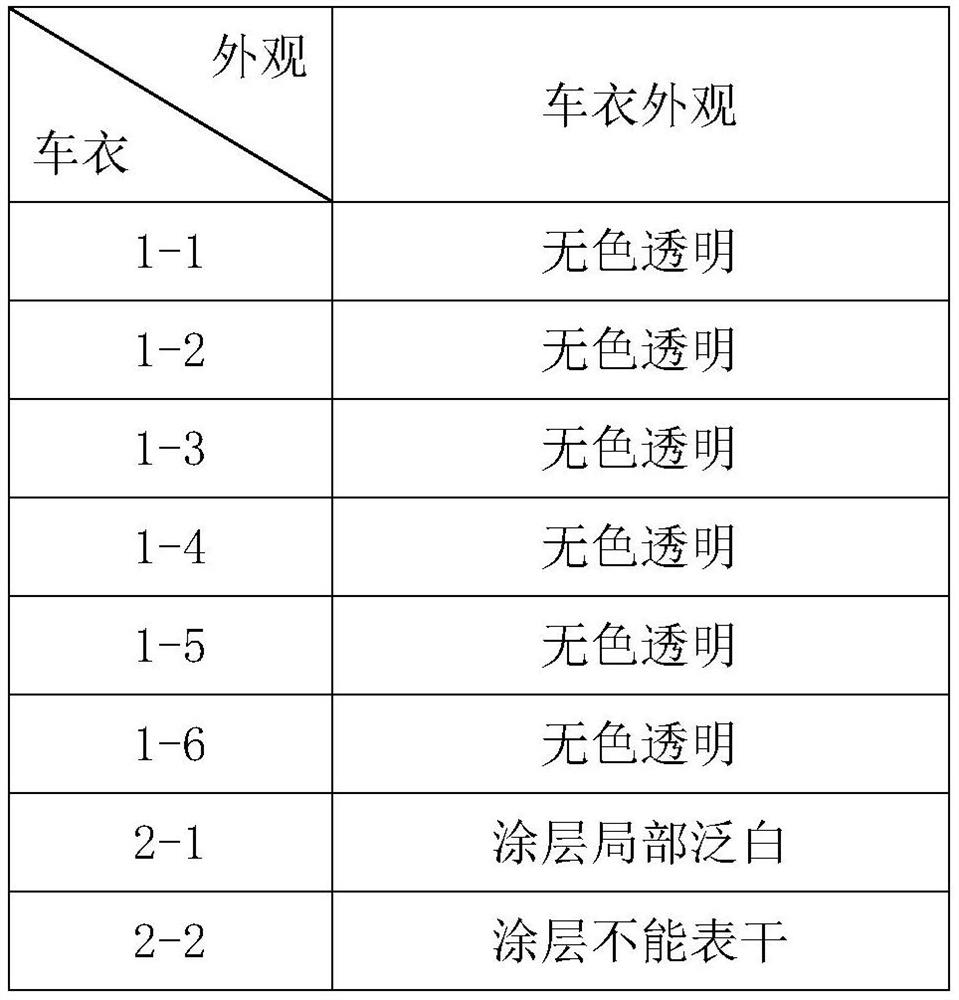

Embodiment 1

[0036] This embodiment provides a kind of anti-yellowing and highly transparent invisible car covering. The raw materials of the car covering include the following components and the parts by mass: 1000 parts of polycarbonate diol, 250 parts of isocyanate, 70 parts of chain extender, 10 parts of leveling agent, 10 parts of catalyst, and 2000 parts of solvent; among them, PCDL2000 is selected for polycarbonate diol, isophorone diisocyanate (IPDI) is selected for isocyanate, triethanolamine is selected for chain extender, and BYK is selected for leveling agent BYK333 leveling agent, the catalyst is dibutyltin dilaurate, the solvent is ethyl acetate; the car coating base film is Kaiyang 277TPU.

[0037] The preparation method of anti-yellowing high transparency invisible car clothing in the present embodiment comprises the following steps:

[0038]S01, weigh 1000 parts of PCDL2000 polycarbonate diol, 250 parts of isophorone diisocyanate (IPDI), 70 parts of triethanolamine and 200...

Embodiment 2

[0042] This embodiment provides a kind of anti-yellowing and highly transparent invisible car covering. The raw materials of the car covering include the following components and the parts by mass: 1500 parts of polycarbonate diol, 350 parts of isocyanate, 100 parts of chain extender, 20 parts of leveling agent, 15 parts of catalyst, and 3000 parts of solvent; among them, polycarbonate diol is selected from PCDL2000, isocyanate is selected from isophorone diisocyanate (IPDI), chain extender is selected from triethanolamine, and leveling agent is selected from BYK BYK333 leveling agent, the catalyst is dibutyltin dilaurate, the solvent is ethyl acetate; the car coating base film is Kaiyang 277TPU.

[0043] The preparation method of anti-yellowing high transparency invisible car clothing in the present embodiment comprises the following steps:

[0044] S01, weigh 1500 parts of PCDL2000 polycarbonate diol, 350 parts of isophorone diisocyanate (IPDI), 100 parts of triethanolamine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com