Suspension thrust bearing unit

A technology for thrust bearings and suspensions, applied in the direction of suspensions, elastic suspensions, rolling contact bearings, etc., can solve the problems of increased damping device wear, lower cover fatigue, cracking, etc., and achieve the effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

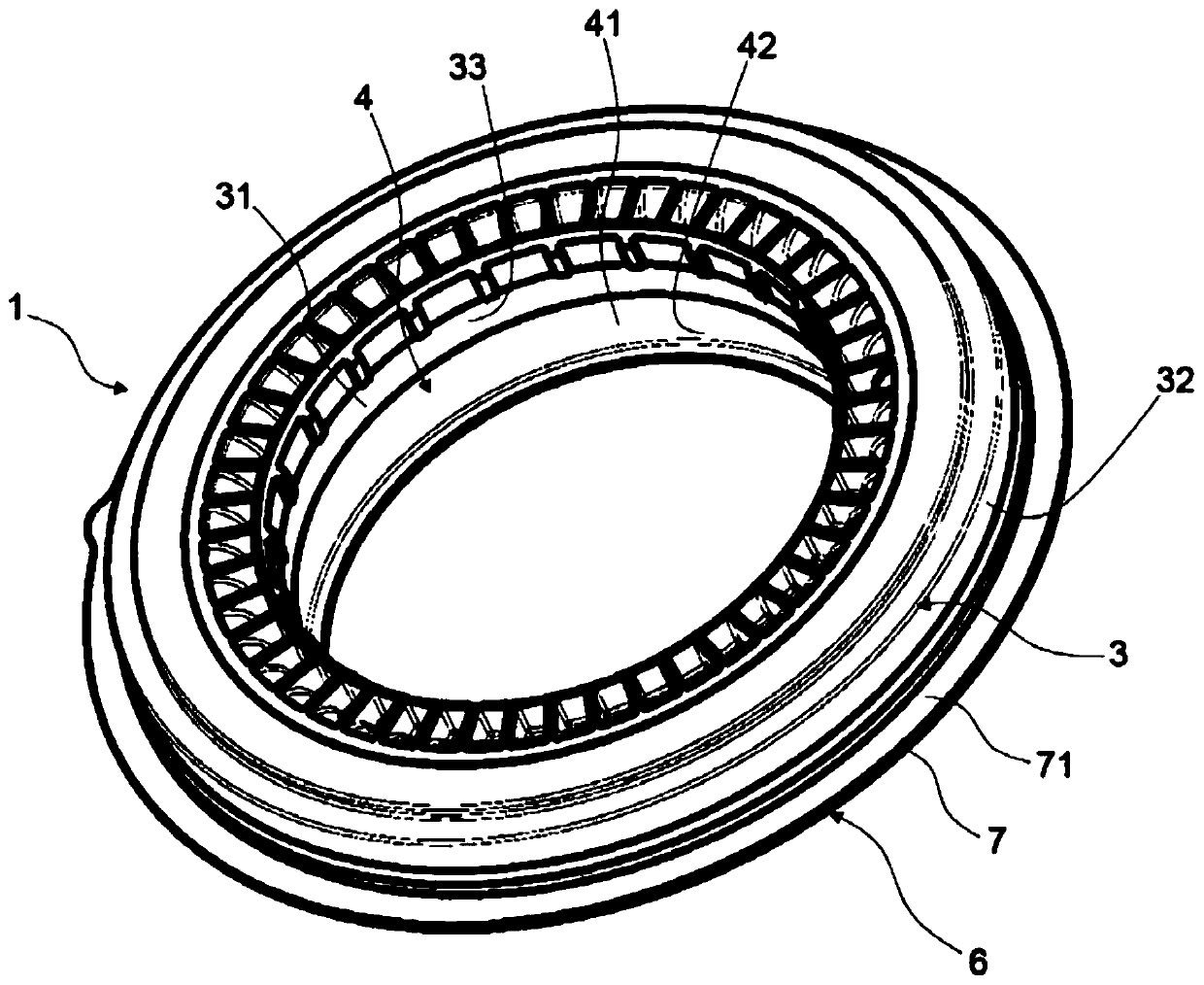

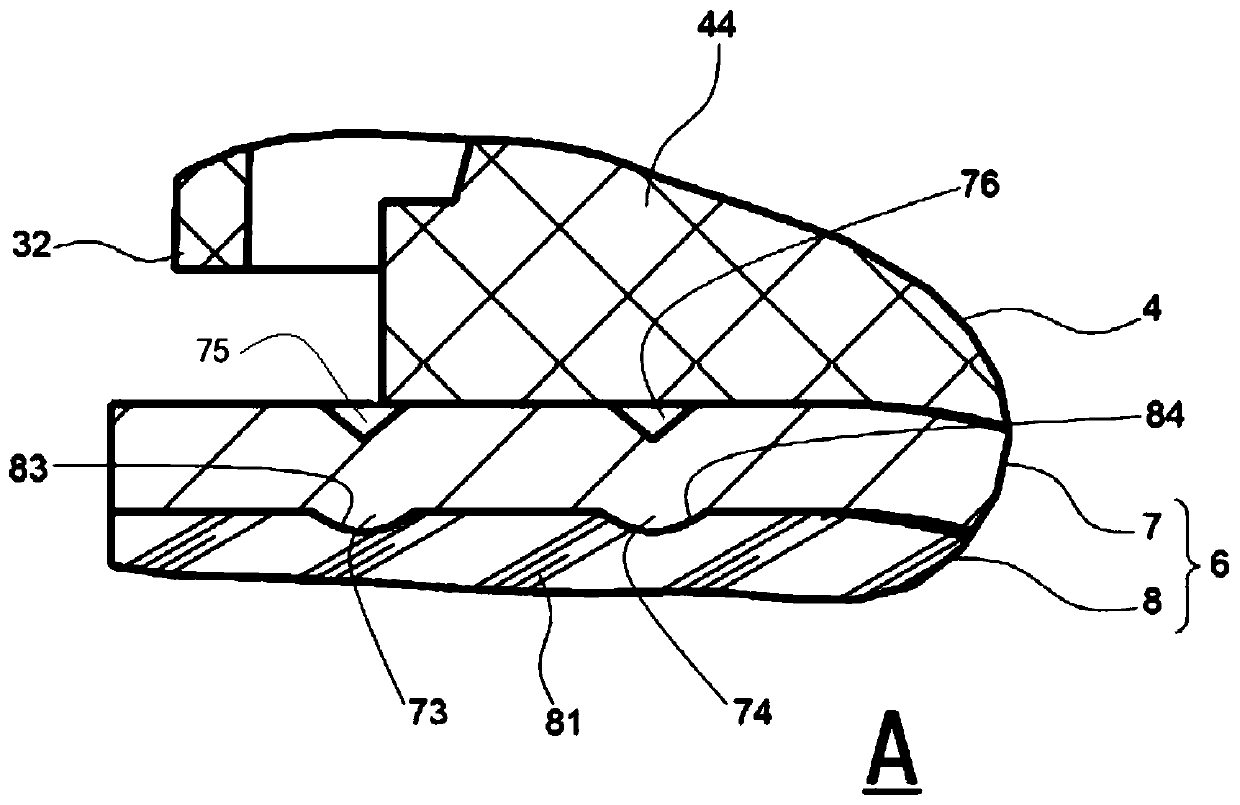

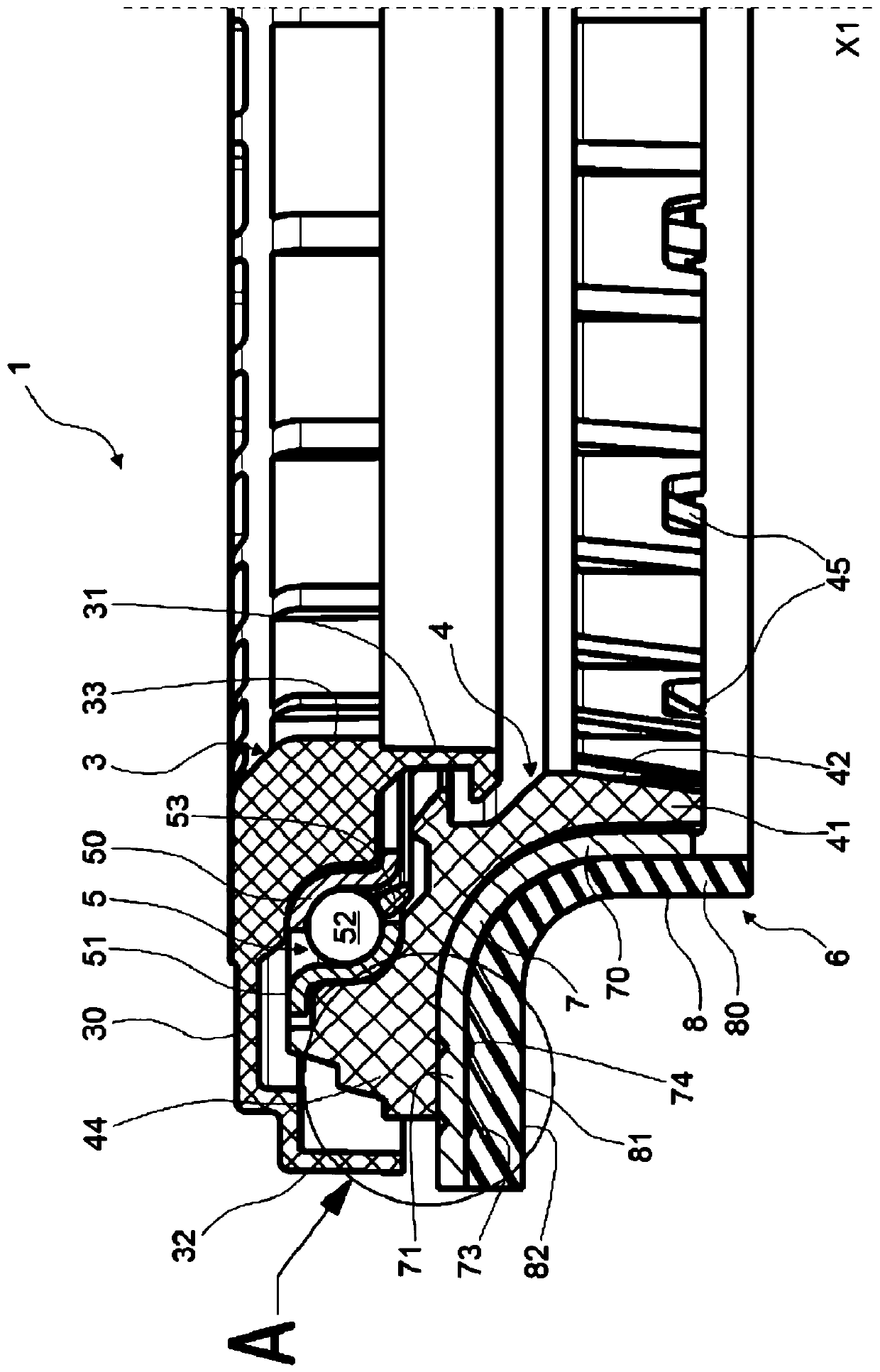

[0039] A suspension thrust bearing unit 1 having a central axis X1 is installed between a support block (not shown) connected to the chassis of the motor vehicle and a helical suspension spring (not shown) . Such a suspension thrust bearing unit 1 can be used, for example, in an automobile MacPherson strut assembly.

[0040] In the following, the adjectives “axial” and “radial” are defined with respect to the central axis X1 of the annular thrust bearing 1 .

[0041] The suspension thrust bearing unit 1 includes an annular upper cover 3 , an annular lower cover 4 and a single rolling bearing 5 . These three assemblies 3, 4 and 5 have an overall circular shape around the central axis X1.

[0042] The upper cover 3 consists of a one-piece part made of a plastic composite material, for example of polyamide, optionally reinforced with glass fibres. The upper cover 3 has an upper radial portion 30 , an annular inner skirt 31 and an annular outer skirt 32 . The annular inner ski...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com