Scaffolding framework mounting process and related scaffolding framework

A scaffolding and frame technology, applied in the direction of house structure support, house structure support, transportation and packaging, etc., can solve the problems of increasing the difficulty of assembly, prolonging the time, and deteriorating the coating cost of the cargo compartment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

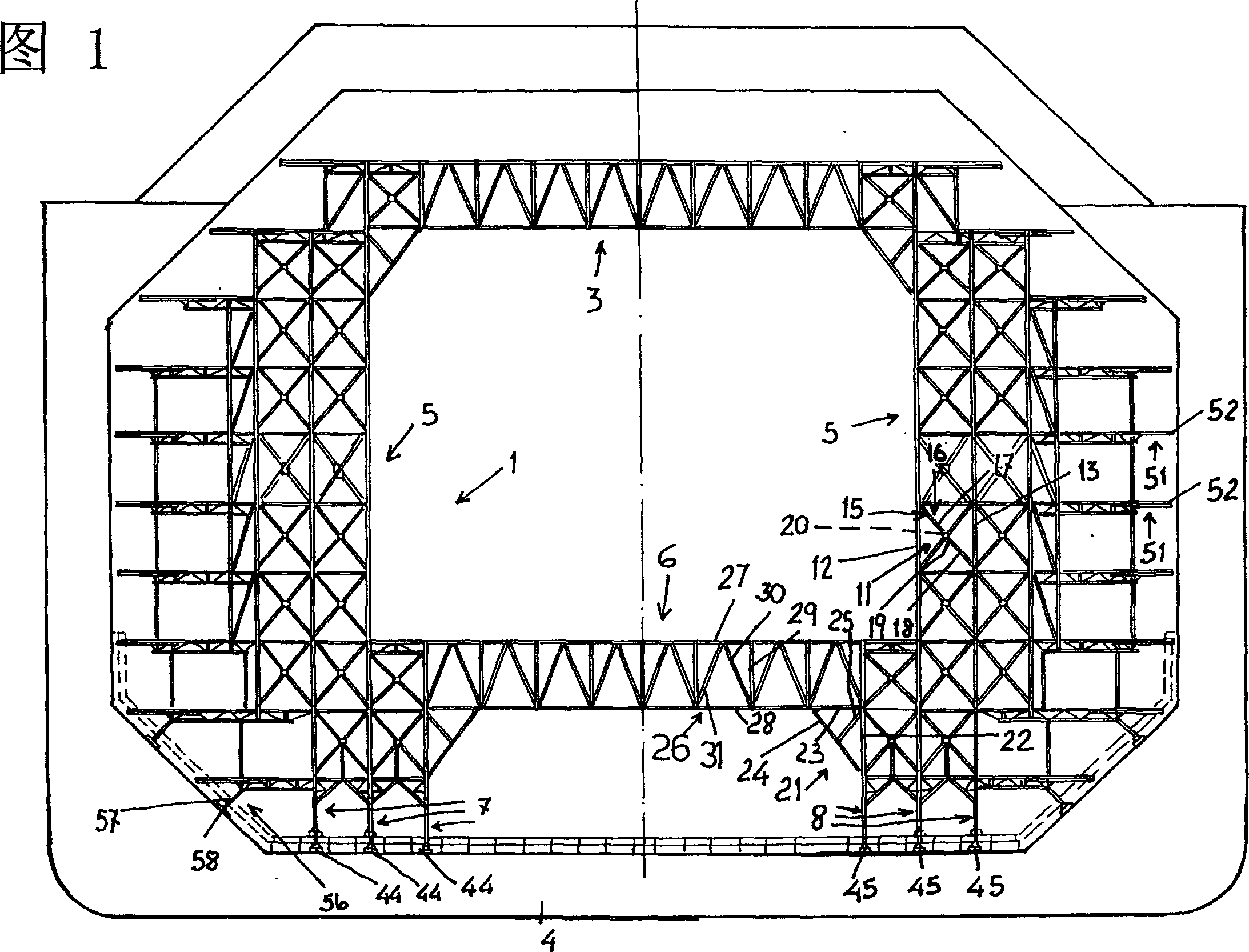

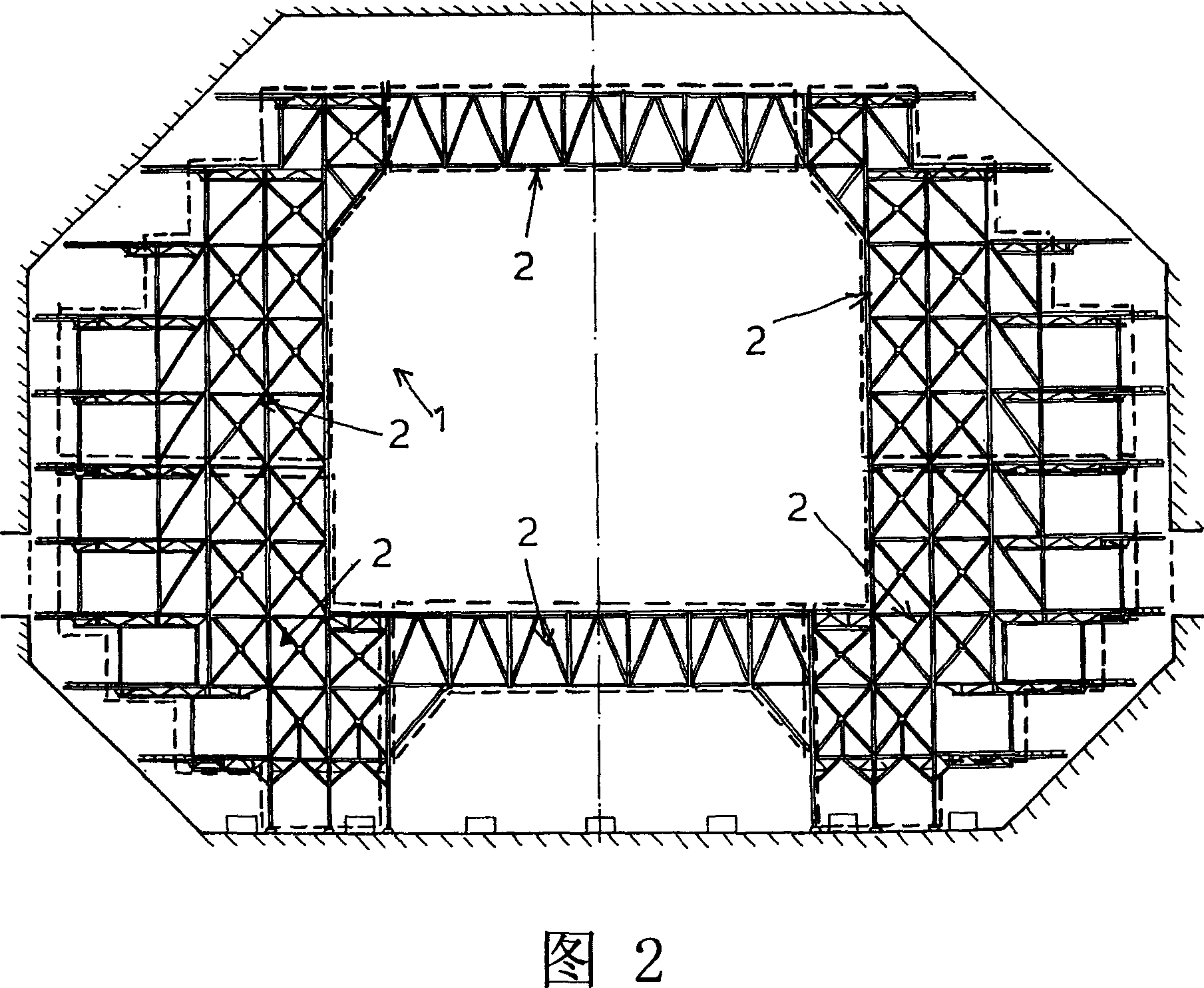

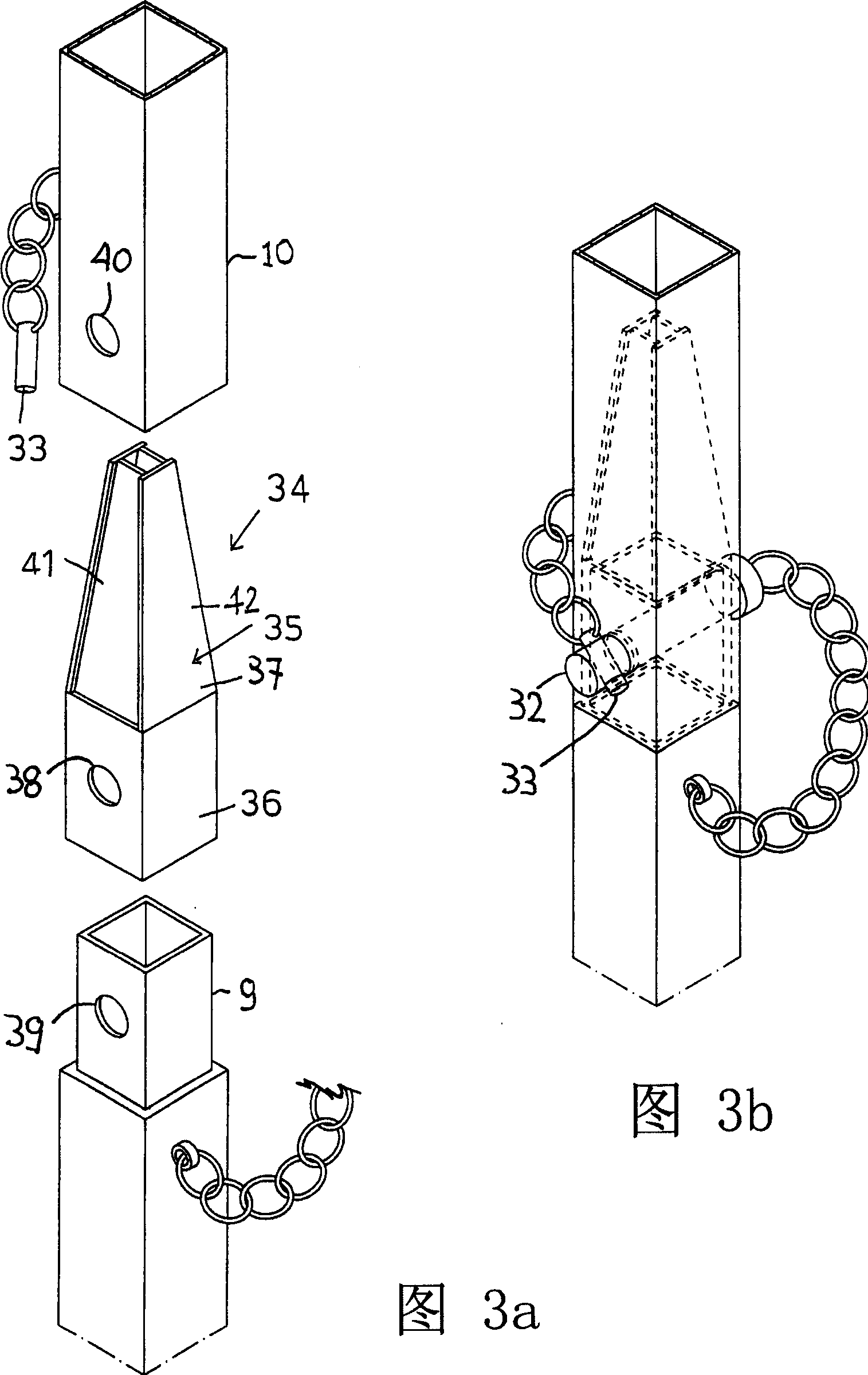

[0030] See the cited figure showing a scaffolding structure for laying the coating of the cargo hold of a vessel transporting liquefied natural gas, the entire scaffolding structure being indicated by the reference number 1 .

[0031] The structure of the scaffolding 1 comprises blocks 2 which in turn are made of polygonal modules.

[0032] The assembly of the modules combined to form the individual blocks 2 is advantageously carried out outside the cargo hold 4 of the ship, while the blocks 2 thus obtained are assembled together inside the hold 4 of the ship.

[0033] This can provide several advantages.

[0034] First of all, it allows the assembly and dismantling of the scaffolding 1 and the laying of the coating of the cargo hold to be carried out independently of the construction phase of the vessel, since there is a wide adjustment space inside the cargo hold 4 of the vessel, which can allow both operations to be carried out even simultaneously, while one An operation d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com