Assembly of units for building an unvulcanised or green tyre for vehicles

A technology for unit components and tires, applied in tires, applications, household appliances, etc., can solve the problems of bulky unit components and large logistics, and achieve the effect of simplifying logistics, improving production capacity, flexibility and logistics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

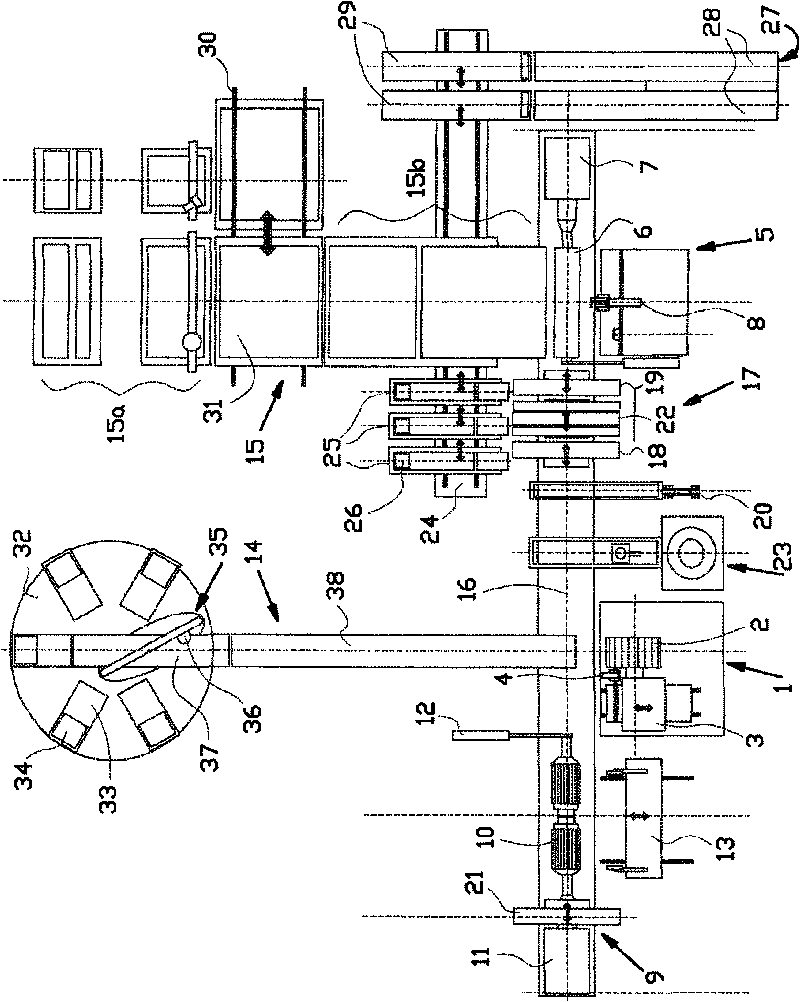

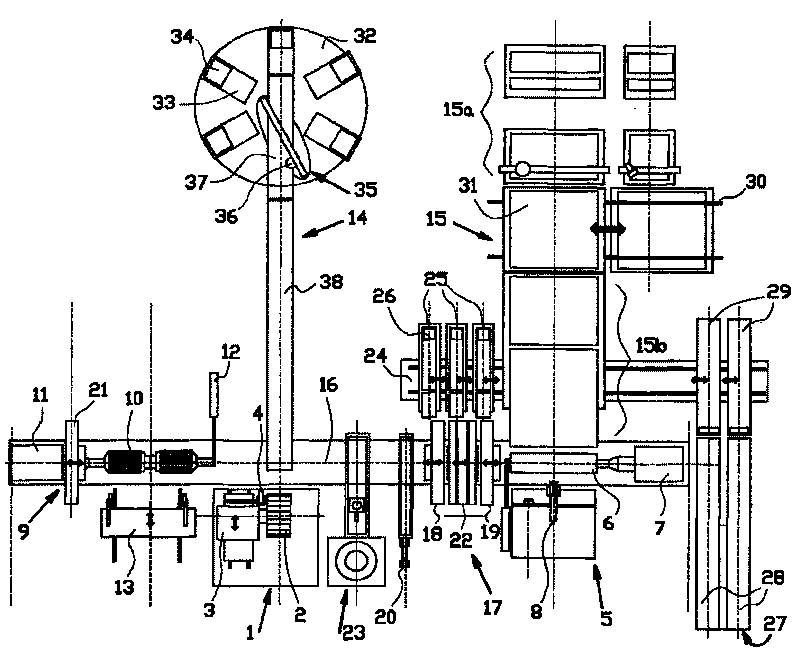

[0012] figure 1 An exemplary arrangement of unit assemblies for manufacturing an unvulcanized or green tire for vehicles is schematically shown. This component is especially suitable for the manufacture of so-called off-the-road tires.

[0013] The assembly comprises a first unit 1 with a breaker-making drum 2 , a drive 3 for the breaker-making drum 2 and means for pressing the breaker material to be placed on the breaker-making drum 2 Pressing device 4. The cushion building drum 2 may be moved transversely to the first conveyor track 16 between a position directly above the first conveyor track 16 (discussed further below) and a position adjacent to the first conveyor track 16 and spaced therebetween. Such breaker production drums are known per se and will therefore not be described in further detail here.

[0014] The assembly also comprises a second unit 5 with a carcass building drum 6 , a drive 7 for the carcass building drum 6 and for pressing the carcass material to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com