Storing apparatus for rod-shaped articles and apparatus and method for filling storing apparatuses

A technology for storing equipment and objects, which is applied in storage devices, packaging, food science, etc., and can solve the problems of low output of equipment, long time for filling and emptying, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

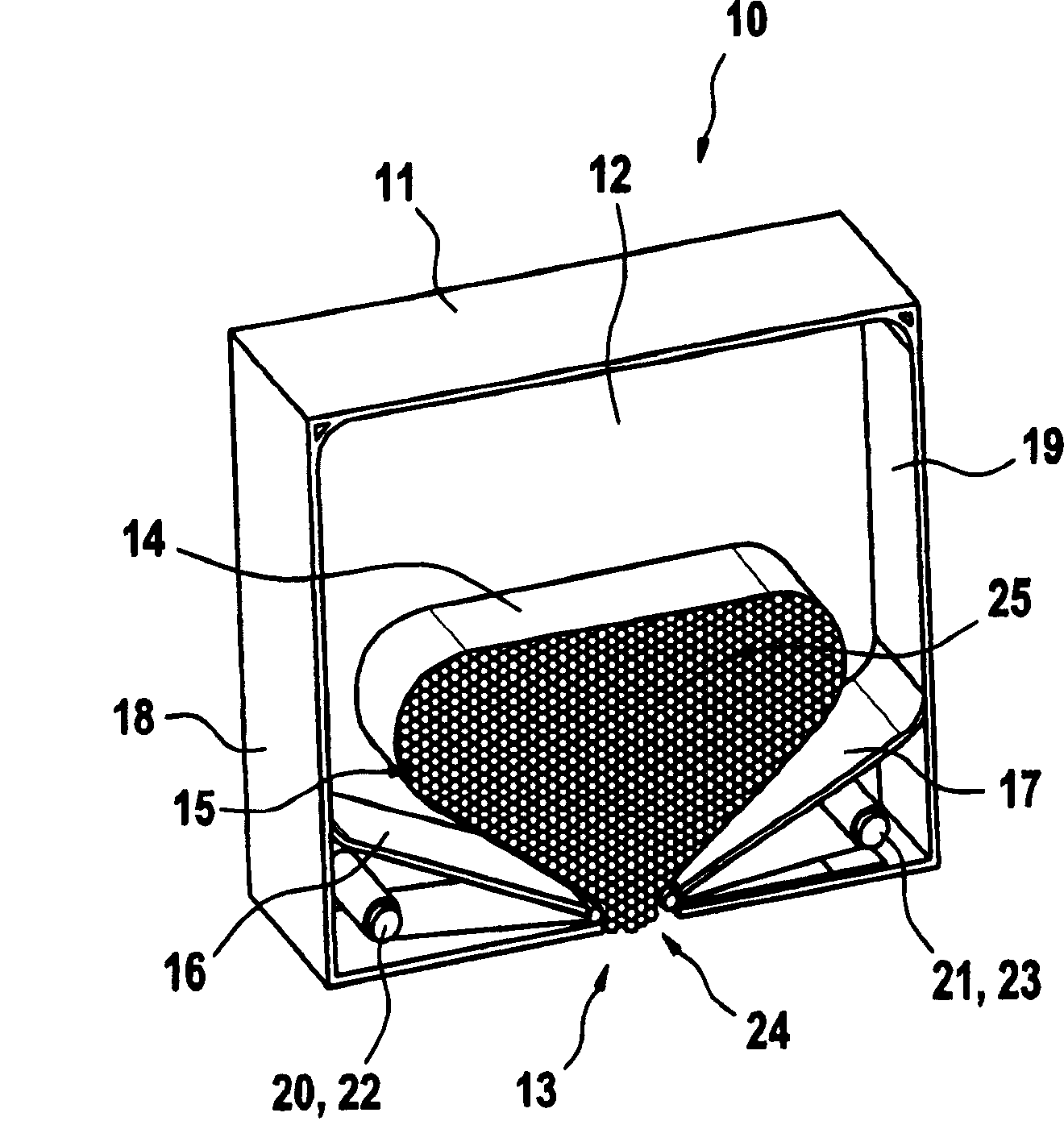

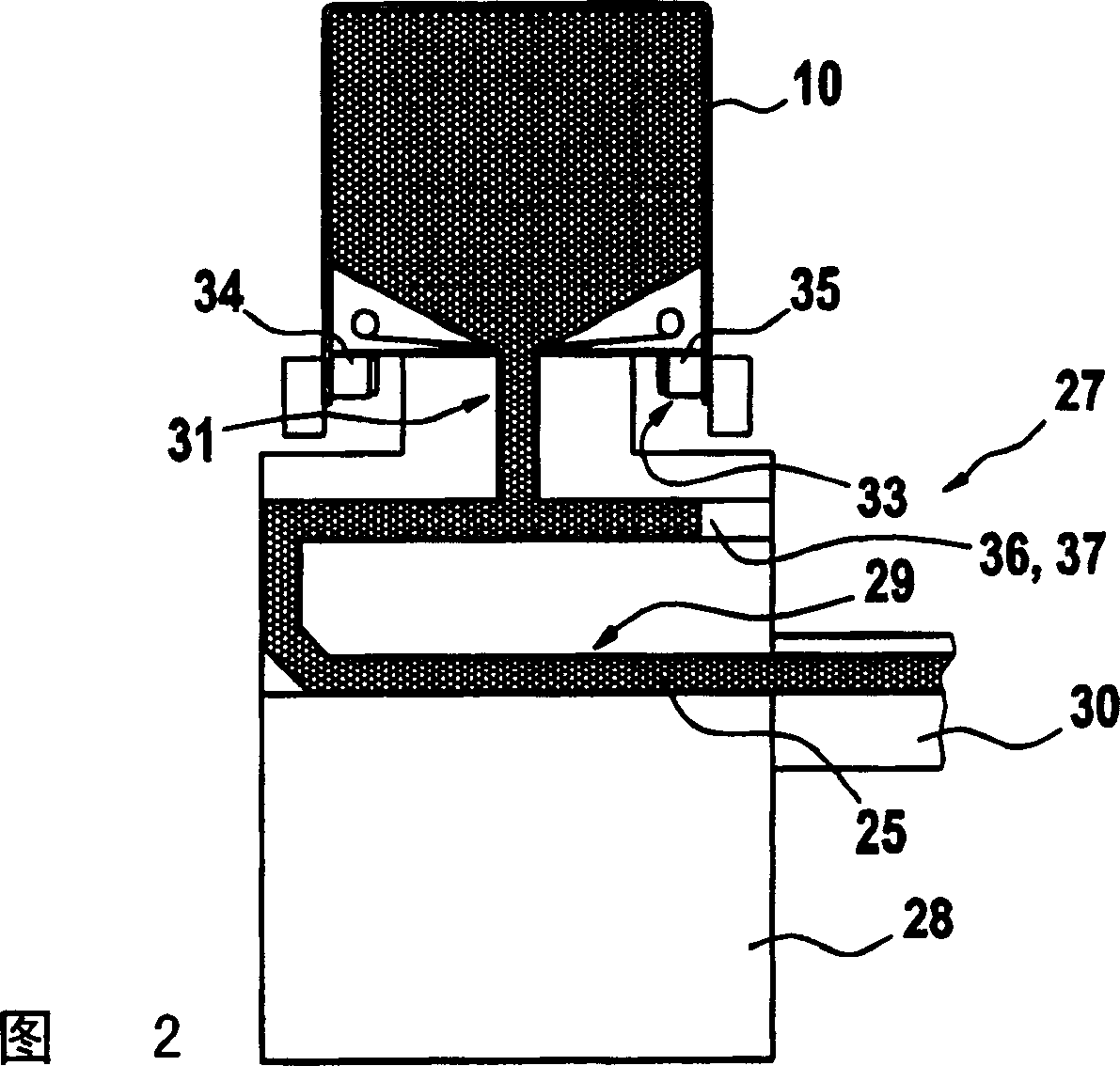

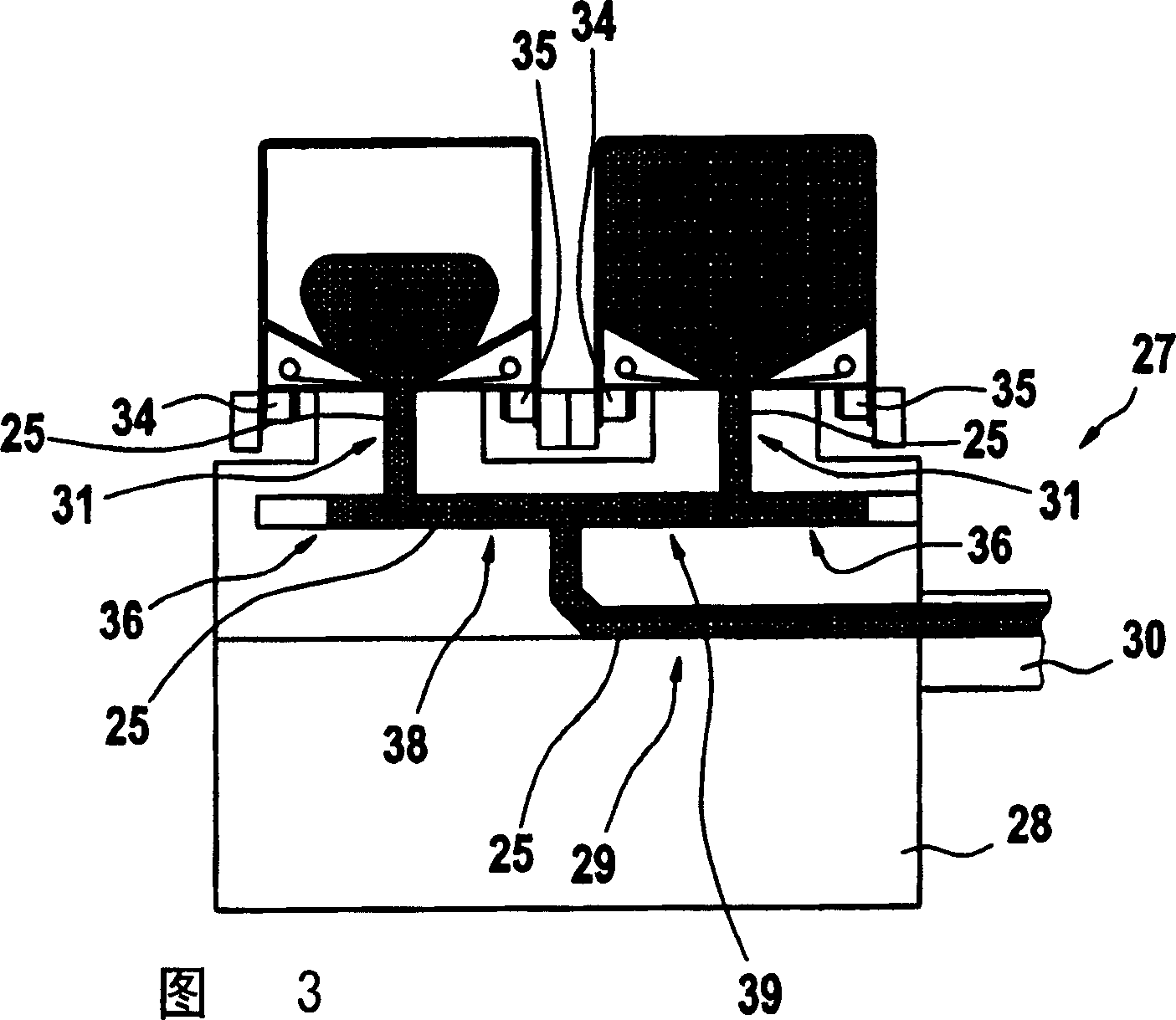

[0021] In the drawings, storage devices for rod-shaped articles in the tobacco manufacturing industry are shown, as well as devices and methods for filling these storage devices. Of course, these devices and methods can also be used to store and transport other items.

[0022] in the attached figure 1 A removable storage device 10 is shown in . The storage device 10 can be used for storing and transporting rod-shaped items, such as filters, which are arranged in the same position within the storage device 10 . The storage device 10 comprises a housing 11 defining a storage chamber 12 closed on all sides, provided with at least one port 13 for filling and emptying the storage device 10 . A flexible belt piece 14 is provided in the housing 11 or storage compartment 12 . Belt member 14 may have a prescribed initial tension or belt tension. The enlarged storage space 15 in the storage chamber 12 can be variably adjusted as a function of the filling level via the flexible lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com