Rapid assembling method for enlarged zone stove shell and lining structure of dome-combustion hot stove

An assembly method and hot blast stove technology, applied to brick blast furnaces, etc., can solve the problems of many variable diameter belts, waste of mechanical platforms, and occupation of assembly platforms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is further illustrated below by specific examples.

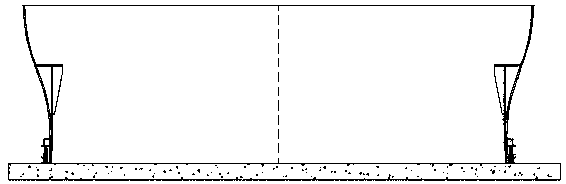

[0017] figure 1 The rapid assembly method of the enlarged furnace shell and lining structure of the top-fired hot blast stove shown includes:

[0018] Step 1. Assemble and weld the furnace shell at the lower straight section of the S-curve on the assembly platform, and level the upper part of the entire furnace shell, retest and correct the ellipticity;

[0019] Step 2. Based on the center of the straight furnace shell, draw the diameter projection of the upper opening of the S-curved enlarged belt on the ground of the assembly platform, and assemble the furnace shell with the S-curved enlarged belt on the upper part of the straight furnace shell;

[0020] Step 3. The installation position of the vertical rib plate of the supporting brick plate is positioned on the inner wall of the furnace shell with S-bend expansion belt;

[0021] Step 4. Groove the liner and hoist it in pieces according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com