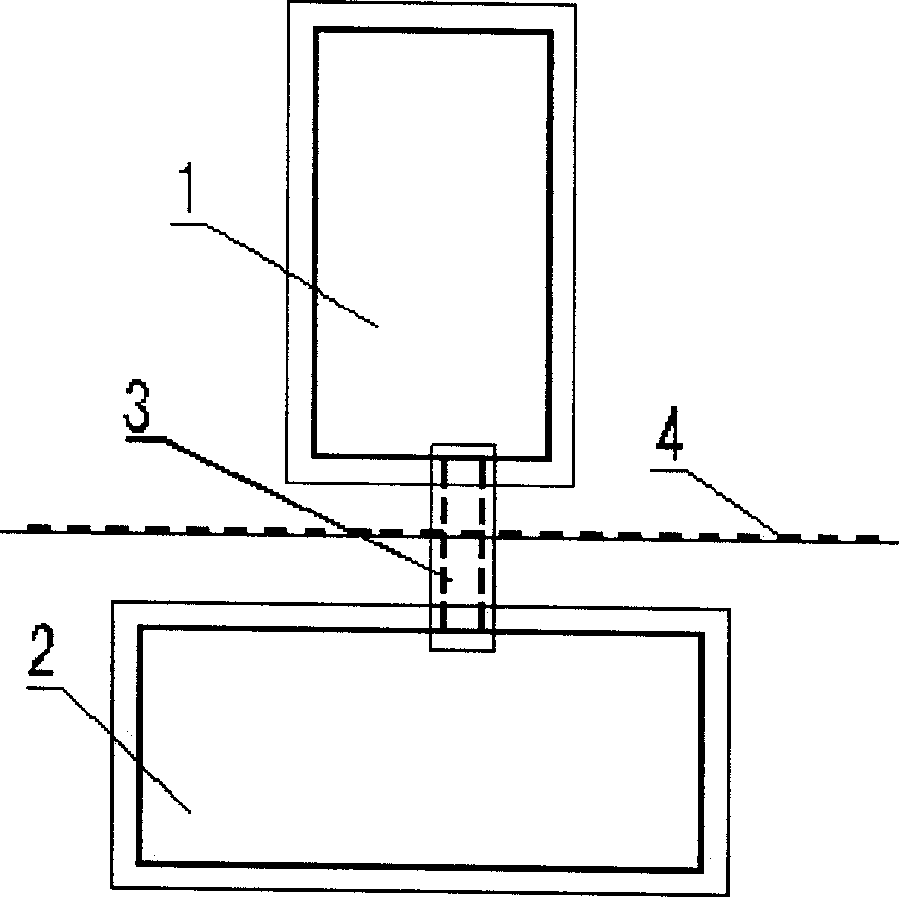

Arrangement structure of carbon block transferring station and anode assembling shop in anode factory

A technology of assembly workshop and configuration structure, applied in industrial buildings and other directions, can solve the problems of rising investment and production and operation costs of factories and enterprises, increasing vehicle and road maintenance and maintenance costs, and unreasonable configuration of anode assembly workshops, reducing transportation. The effect of vehicle and road paved area, reduction of production and operation costs, and reduction of factory land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Embodiments of the present invention: during the construction of the anode factory, the carbon block transfer station (1) is arranged at a higher position, and the anode assembly workshop (2) is arranged at a low place, and then the carbon block transfer station (1) and the anode An underground conveying tunnel (3) is built between the assembly workshops (2), so that the underground conveying tunnel (3) connects the carbon block transfer station (1) and the anode assembly workshop (2); in order to reduce the carbon block transfer station (1 ) and the anode assembly workshop (2), a retaining wall (4) can be built between the carbon block transfer station (1) and the anode assembly workshop (2) to separate them.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com