A mine material transportation scheduling system and method

A scheduling system and material technology, applied in transportation, packaging, storage devices, etc., can solve problems such as unsuitable mine material transportation scheduling, and achieve the effect of office automation, convenient scheduling management, and unified scheduling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

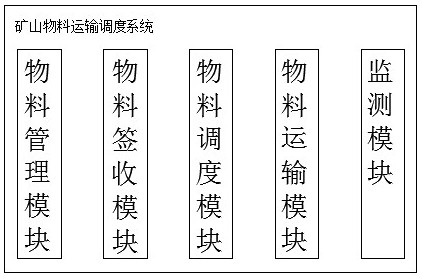

[0052] like figure 1 As shown, a mine material transportation scheduling system includes a material management module, a material receipt module, a material scheduling module and a material transportation module;

[0053] The material management module is used to receive the material application from the material receipt module, and send instructions to the material scheduling module to arrange personnel loading;

[0054] The material receipt module is used to determine the type, quantity and time of the required materials. After selecting the material transfer method, submit a material application to the material management module, and make financial changes according to the proposed material application. After receiving the delivery from the material scheduling module After the arrival notice, confirm the receipt, and arrange personnel to unload and dispatch the vehicle after confirming the receipt;

[0055] The material scheduling module is used to query the number and loc...

Embodiment 2

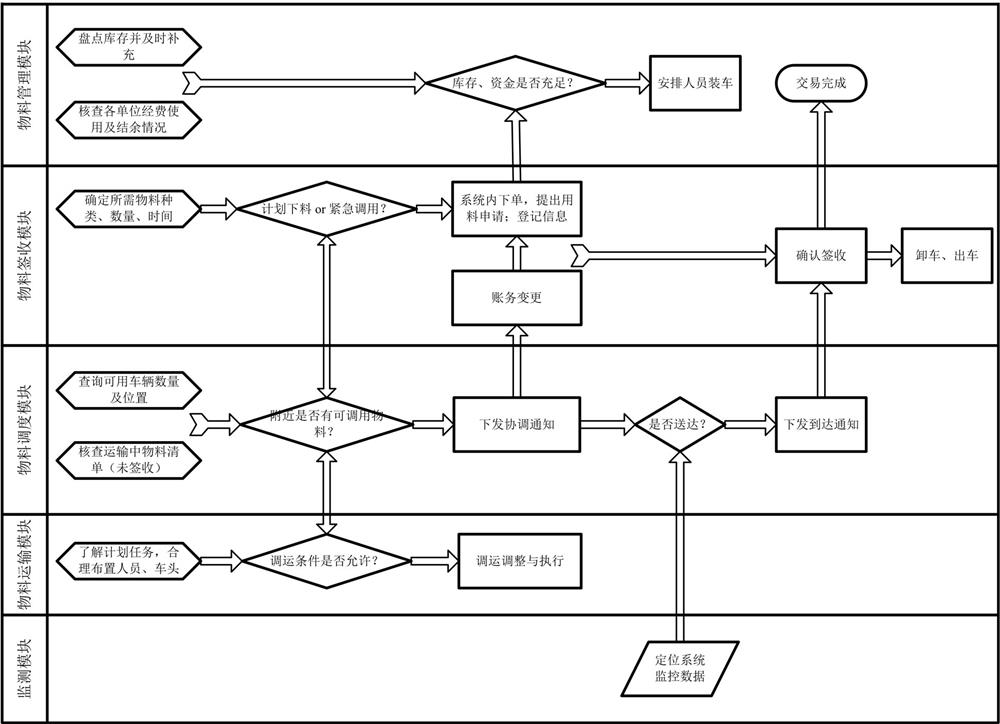

[0063] like figure 2 As shown, a mine material transportation scheduling method includes the following steps:

[0064] Step 1. The material receipt module determines the type, quantity and time of the required materials according to the actual needs, selects the material transfer method and submits a material application to the material management module, and transmits the material transfer method to the material scheduling module;

[0065] Step 2. After receiving the material application from the material receipt module, the material management module checks the inventory and funds, and after confirming that the inventory and funds meet the requirements, sends an instruction to the material scheduling module to arrange personnel loading;

[0066] Step 3. After the material scheduling module receives the order to arrange personnel loading from the material management module, it inquires the number and location of available vehicles, and inquires about the materials that can b...

Embodiment 3

[0071] The difference from Embodiment 2 is that in step 3, the material scheduling module also needs to check the list of materials that have not been signed for during transportation.

[0072] In step 5, after the material is delivered to the material receipt module, the material scheduling module sends material monitoring data to the monitoring module.

[0073] The present invention can optimize the existing mine material transportation scheduling work: specialized management, reducing cross links; unified scheduling, avoiding transportation conflicts; comprehensive coordination, optimizing resource allocation; real-time information, improving work efficiency; data collection, scientific analysis and management. Through the management platform and underground monitoring system, the office automation of material transportation management has been realized, and the orderly planning and emergency dispatching have been unified through new management ideas. This design not only r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com