Process and apparatus for preparing sodium sulfite in production of ion-film caustic soda

A technology of ionic membrane caustic soda and sodium sulfite, which is applied in the field of chemical technology, can solve the problem of high procurement cost, and achieve the effect of reducing production cost and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

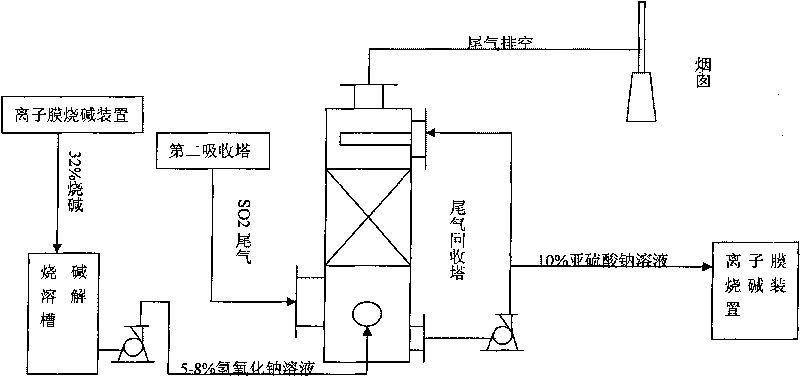

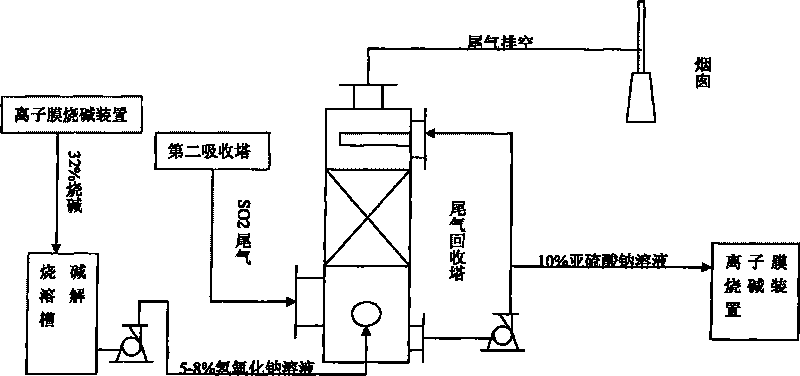

[0017] A preparation process of sodium sulfite in the production of ion-exchange membrane caustic soda, which transports 32% of the total mass of caustic soda in the ion-exchange membrane caustic soda device to the caustic soda dissolving tank, is prepared into a sodium hydroxide solution with a mass concentration of 5%, and then oxidizes the The sodium solution is sent to the tail gas recovery tower to react with the sent sulfur dioxide tail gas to produce a sodium sulfite solution with a mass concentration of 10%, and the sodium sulfite solution is then sent to the ion-exchange membrane caustic soda plant for continued use.

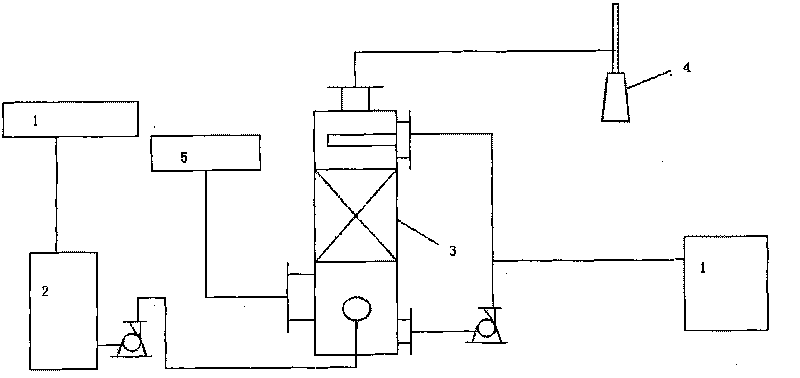

[0018] The equipment for the preparation process of sodium sulfite in ion-exchange membrane caustic soda production includes caustic soda dissolving tank 2 connected to ion-exchange membrane caustic soda plant 1, caustic soda dissolving tank 2 is connected to tail gas recovery tower 3 through pipelines, tail gas recovery tower 3 communicates with sulfur d...

Embodiment 2

[0020] A preparation process of sodium sulfite in the production of ion-exchange membrane caustic soda, which transports 32% of the total mass of caustic soda in the ion-exchange membrane caustic soda plant to the caustic soda dissolving tank, and is prepared into a sodium hydroxide solution with a mass concentration of 8%, and then oxidizes the The sodium solution is sent to the tail gas recovery tower to react with the sent sulfur dioxide tail gas to produce a sodium sulfite solution with a mass concentration of 10%, and the sodium sulfite solution is then sent to the ion-exchange membrane caustic soda plant for continued use.

[0021] The equipment of the preparation technology of sodium sulfite in ion membrane caustic soda production is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com