Large-inclination-angle climbing type tubular belt conveyor

A technology of pipe belt conveying and large inclination angle, which is applied to conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of major improvement in use function, inconvenience, and inability to realize large inclination angle transportation of pipe belt conveyors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

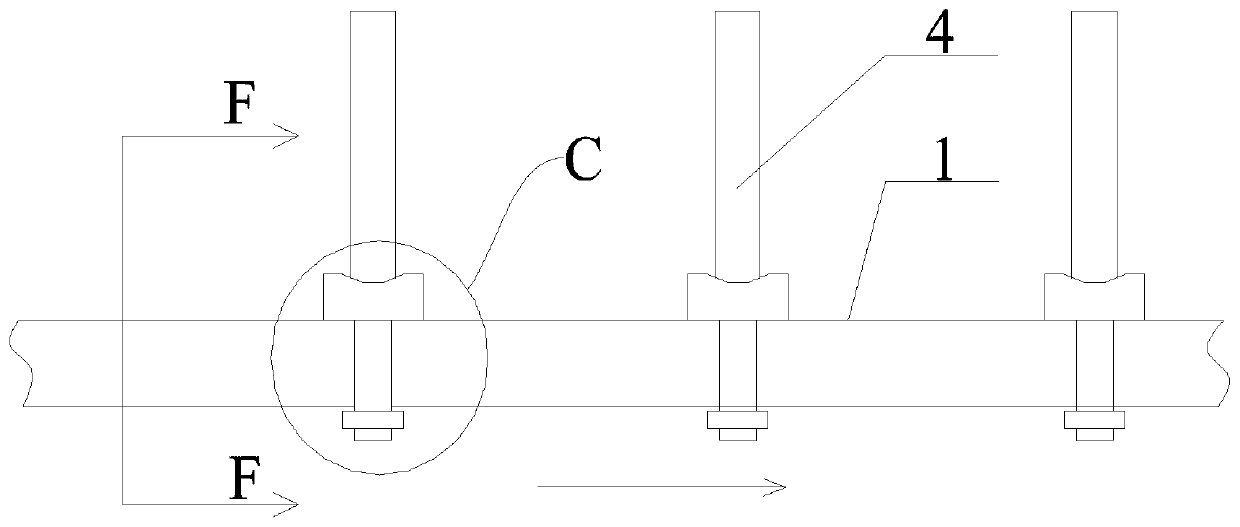

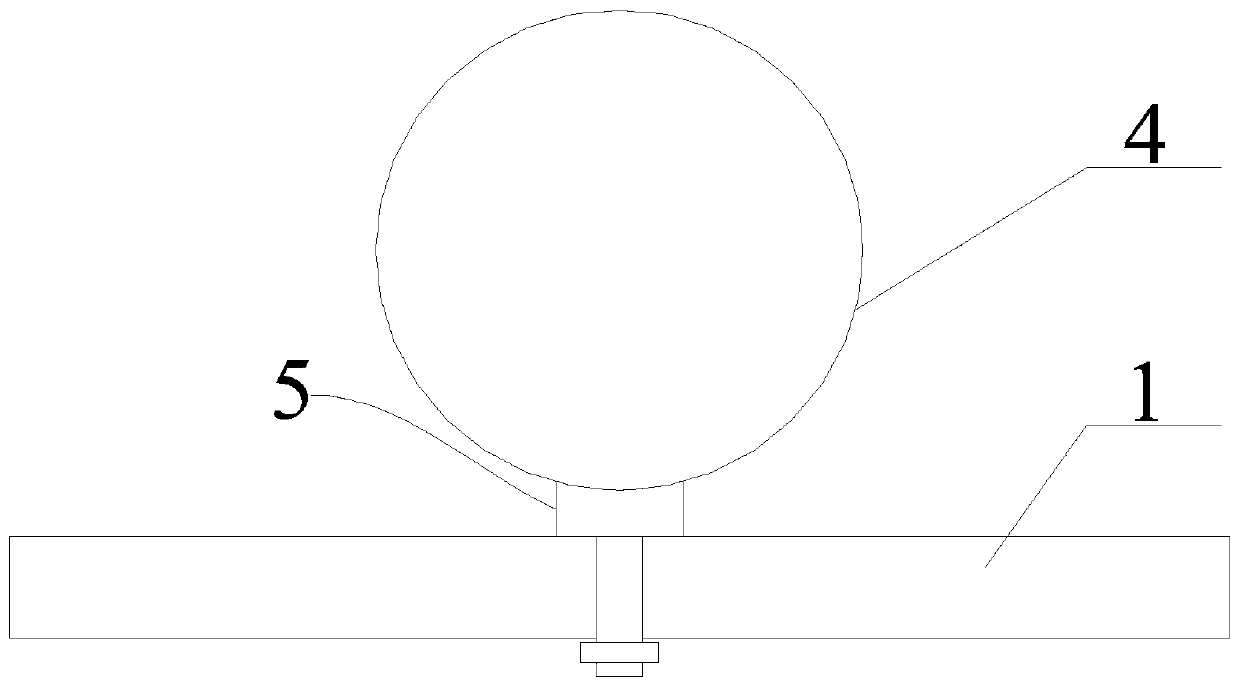

[0097] Embodiment one, see image 3 , the storage mechanism of the present invention is a plurality of retaining discs 4 arranged in parallel along the belt conveying direction, and the retaining discs 4 are arranged on the central axis of the belt 1 . recombine Figure 4 , after the belt 1 is rolled up, the retaining disc 4 fills the section of the round tube and divides the round tube into multiple chambers. The distance between two adjacent blocking trays 4 is no more than 0.5 meters. Those skilled in the art can make adaptive settings according to the specification of the specific belt.

[0098] see Figure 8 , as a preferred method, the fixing block 51 of the present invention is provided with a mounting groove 53; the retaining plate 4 can be fixed in the mounting groove 53 by bonding or welding;

[0099] join Figure 9 , as a preferred method, the fixing block 51 of the present invention is also provided with two installation clips 54, the retaining plate 4 can be ...

Embodiment 2

[0101] Embodiment two, see Figure 10 , the material storage mechanism of the present invention is a multi-lobed type material storage mechanism, and each multi-lobed type material storage mechanism all includes some retaining discs 4 that are evenly arranged along the width direction of the belt 1; Figure 11 , after the belt 1 is rolled up, the retaining discs 4 overlap each other to fill the section of the round tube to form a material storage structure. The number of retaining discs 4 is at least 3, and there is a small gap after being rolled up, which can be applied to the conveying of bulk materials. More preferably, the number of the retaining discs 4 of the present invention is preferably 4, 6 or 8, so that the gap after overlapping is smaller and suitable for conveying finer materials. For avoiding that each retaining disk 4 rotates, can also be set as Figure 6 The limiting block 41 in. In order to prevent the material from being exposed from the gap, it can also ...

Embodiment 3

[0107] Embodiment three, see Figure 15 , the material storage mechanism of the present invention is a cage-type material storage mechanism, including a material blocking plate 4, and a blocking material plate 6 is respectively arranged in parallel on both sides of the material blocking plate 4; Figure 16 , A number of support rods 61 evenly distributed on the same circumference are connected between the blocking plate 4 and the two blocking plates 6 . The material retaining plate 4 is installed on the belt 1 through the fixed assembly 5, and the two blocking plates 6 are not connected with the belt 1. The number of support rods 61 is set to 8-20 according to the specifications of the belt 1 .

[0108] The support rod 61 does not hinder the addition of materials, and also increases the strength of the storage mechanism; Figure 15 After the belt 1 is rounded, the material is divided into two sections in the cage storage mechanism, and the blocking plates 6 of the adjacent t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com