Down-pressing nut replacement system

A silk nut and hydraulic cylinder technology, which is applied in metal rolling, metal rolling stands, manufacturing tools, etc., can solve the problems of long replacement time, labor-intensive, complicated replacement process, etc., to achieve simple structure and reduce personnel strength. , the effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

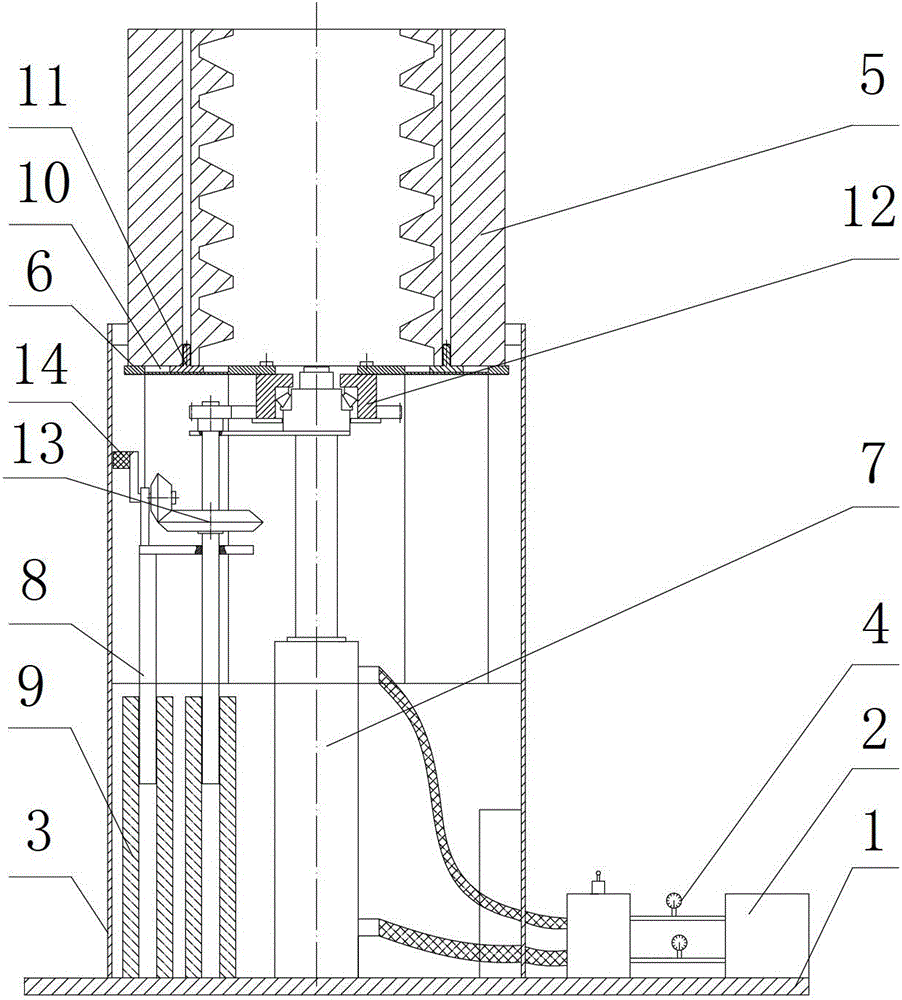

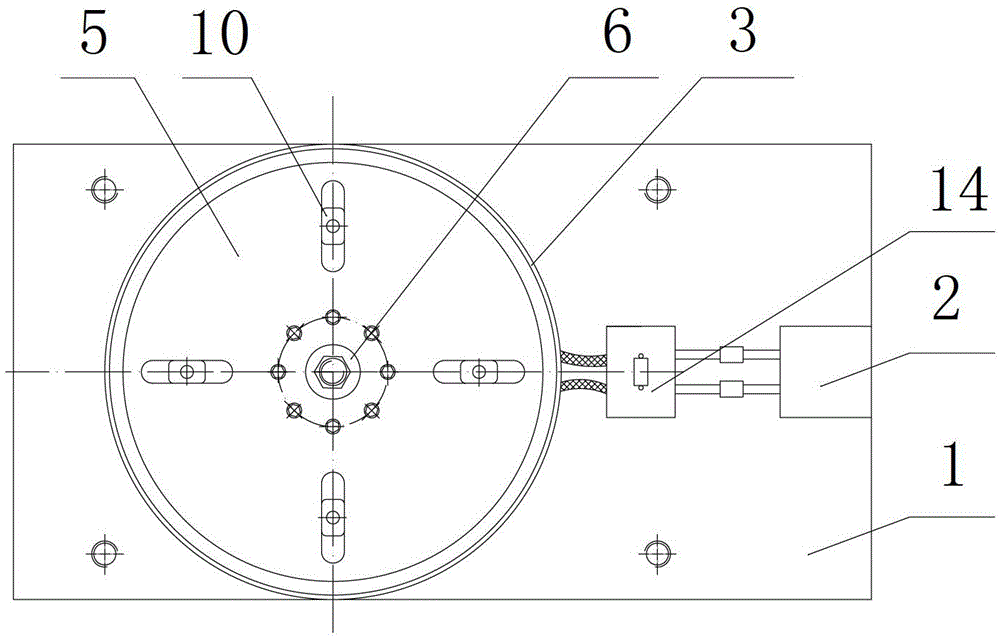

[0040] like figure 1 , figure 2 As shown, a screw nut replacement system provided by the present invention includes an actuator, a control device, a base 1 , a hydraulic pump 2 , a protective cover 3 and a pressure gauge 4 .

[0041] Wherein, the execution device is used to bear the screw nut 5 when the screw nut 5 is replaced, and it includes a load-bearing platform 6 , a hydraulic cylinder 7 , a transmission mechanism, a guide rod 8 and a guide sleeve 9 . The load-bearing platform 6 is used to carry and press down the screw nut 5 . Four positioning slots 10 evenly distributed in the circumferential direction of the load-bearing platform 6, positioning pins 11 are installed in the positioning slots 10, and the positioning pins 11 and positioning slots 10 are installed with transition fit. The present invention adopts 50H7 / k6, according to the size of different nuts , The positioning pins 11 are designed with different diameters. The locating pin 11 and the locating groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com