Mobile type bulk dust-free car loader

A car loader, mobile technology, applied in conveyors, loading/unloading, transportation and packaging, etc., can solve problems such as complex structure and difficult sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

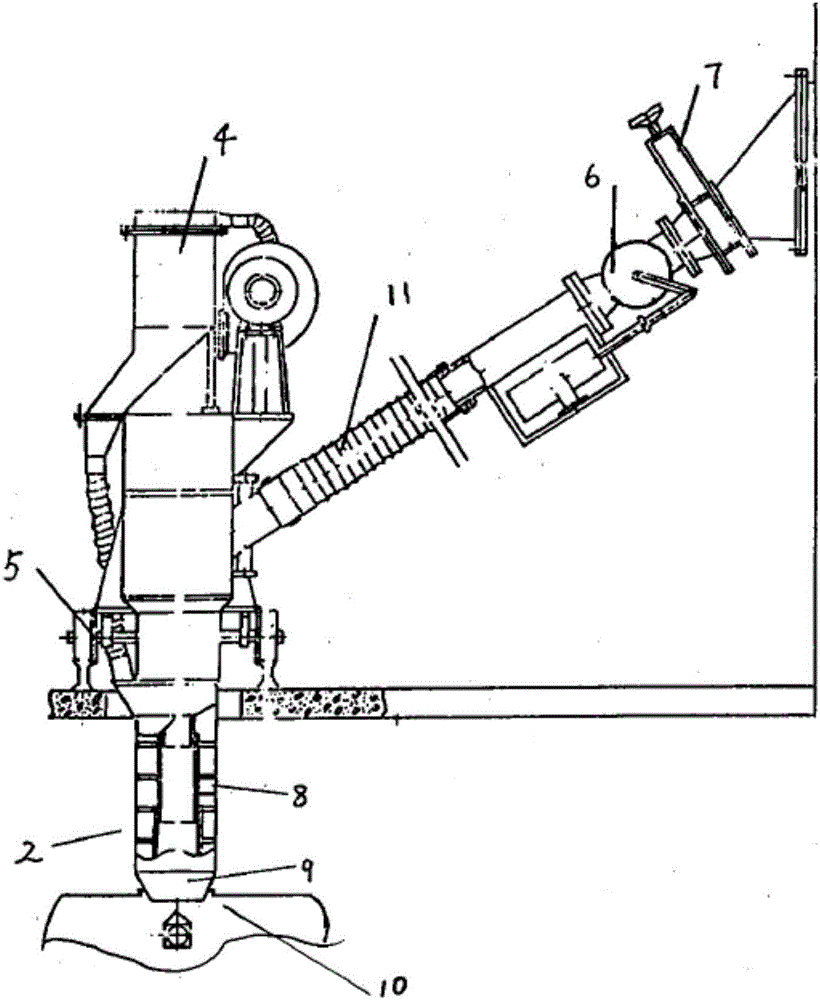

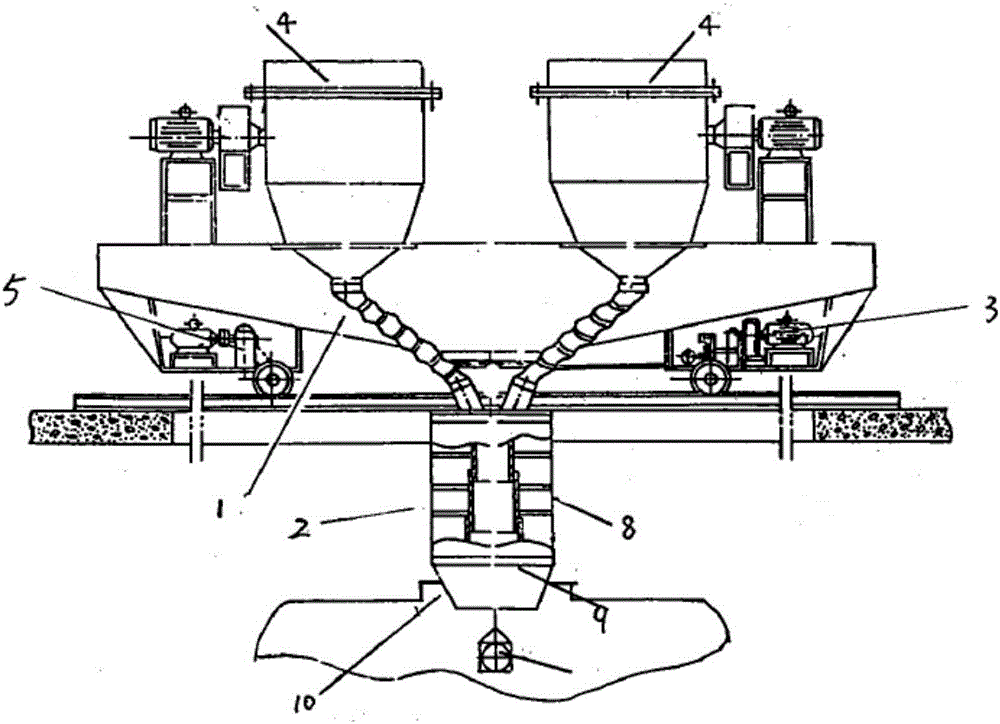

[0010] The details and working conditions of the specific device proposed according to the present invention will be described in detail below in conjunction with the accompanying drawings.

[0011] The present invention consists of a loading machine body 1, a bulk head 2, a bulk head rolling mechanism 3,

[0012] The dust collection device 4, the body walking mechanism 5 and the cement conveying pipeline are composed. The bulk packing head 2 is arranged at the bottom of the vehicle loading machine body 1. The cement conveying pipe is provided with a discharge valve 6 and a gate valve 7. The bulk packing head 2 consists of The secondary shrinking sleeve 8 and the feeding cone 9 are composed of two layers below the telescopic sleeve 8. The feeding cone 9 is compatible with the tank opening 10 and can be tightly sealed. Up and down expansion and contraction, the body walking mechanism 5 adopts the motor traction wheel to walk on the guide rail, the cement delivery pipeline is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com