Thin material threading control method for guide rulers of hot rolling coiler

A technology of hot-rolled coils and guide rails, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems of hot-rolled finished product quality, yield and cost control, and improve the quality of hot-rolled coils And rolling line yield, reduce production costs, improve the effect of coil shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

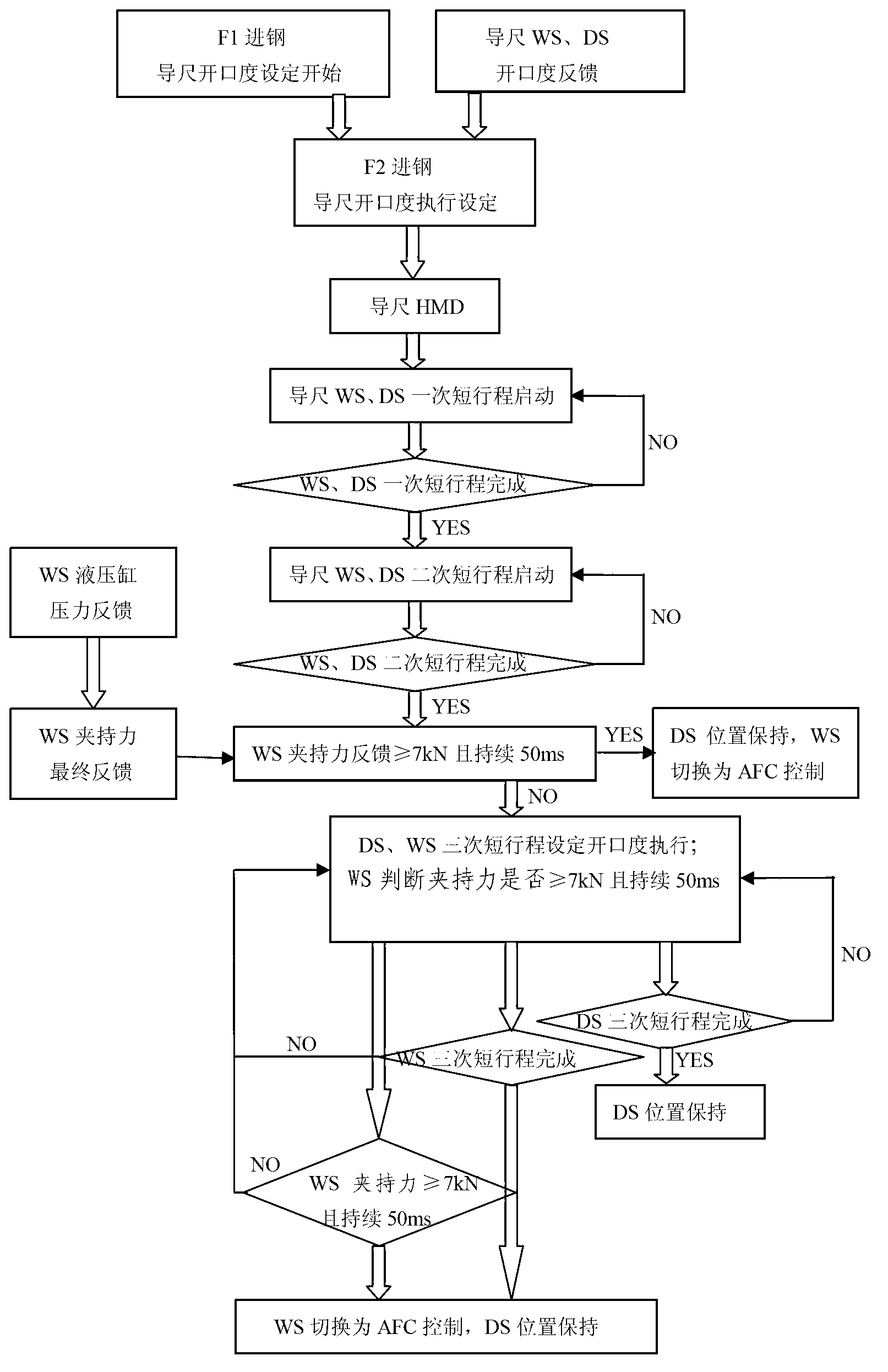

[0020] The method for controlling thin material strip threading of hot-rolled coiler guide ruler of the present invention is based on the original PLC, secondary computer and pressure sensor for detecting the pressure of 2# hydraulic cylinder piston and cylinder rod, and additionally installs a group of detection 1 #Pressure sensor for hydraulic cylinder piston and cylinder rod pressure; at the same time, add M35N analog input board in PLC, and revise and compile guide ruler opening setting program, pressure feedback calculation program, strip steel tracking program, guide ruler opening degree and pressure Automatic control program, when the steel strip is in the action range of the two hydraulic cylinders, the average value of the two pressure feedbacks is used as the actual clamping pressure of the steel plate by the guide ruler.

[0021] The specific control process of the guide ruler is as follows:

[0022] 1. The opening of the guide bar maintains the previous setting. Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com