Composite equipment for flue gas waste heat recovery and dust cleaning

A flue gas waste heat and composite technology, which is applied in the direction of combined devices, chemical instruments and methods, and the separation of dispersed particles, can solve the problems of large space occupation, large flow resistance, and many equipment, so as to improve the purification level, prevent corrosion, The effect of increasing the surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The structure, principle and working process of the present invention will be further described below in conjunction with the accompanying drawings.

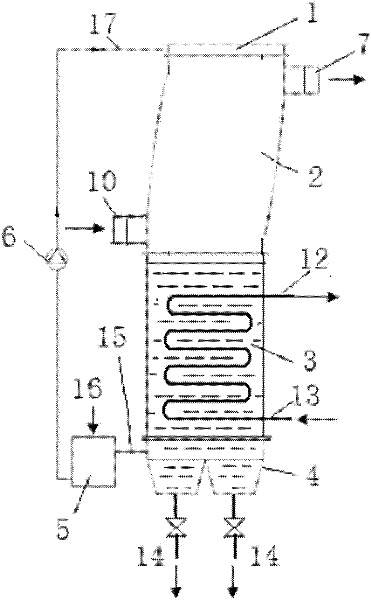

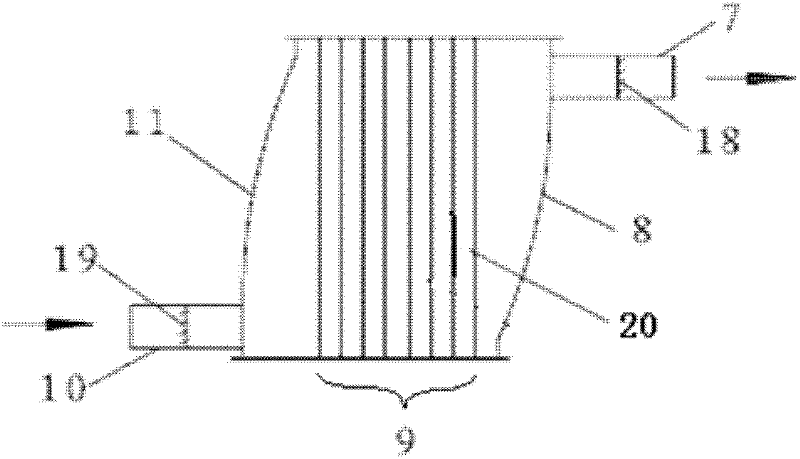

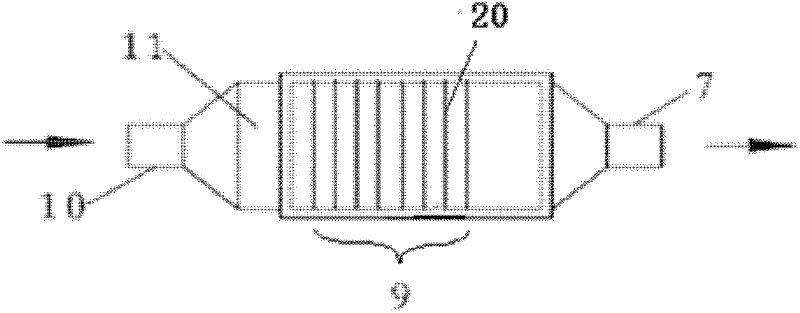

[0020] figure 1 It is a schematic diagram of the overall structure and principle of a flue gas waste heat recovery and dust removal and purification composite equipment provided by the present invention. The equipment includes a heat exchange and absorption composite device 2, a partition heat exchanger 3, a sediment collection and sewage discharge device 4, and a solution pool 5 and liquid pump6. A liquid distributor 1 is arranged on the top of the heat exchange and absorption composite device 2, the partition heat exchange device 3 is located at the bottom of the heat exchange and absorption composite device, and the sediment collection and sewage discharge device 4 is located at the bottom of the partition heat exchange device; the solution pool 5 The inlet is connected to the sediment collection and sewage device thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com