Non-rhenium nickel base single crystal superalloy and preparation method thereof

A high-temperature alloy and nickel-based single crystal technology, which is applied in the field of rhenium-free nickel-based single-crystal superalloy and its preparation, and aeroengine turbine blade materials, can solve the difficulty of increasing the tendency of TCP phase formation, increasing the activity of master alloy smelting, and deteriorating alloys. Microstructure uniformity and thermal corrosion resistance, etc., to achieve the effect of small solidification interval, wide melting temperature range and low alloy cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

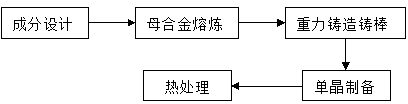

Method used

Image

Examples

Embodiment 1

[0034] (1) Alloy composition design

[0035] The rhenium-free nickel-based superalloy of the present invention has the following alloy components by mass percentage: 7.5%Cr, 5.0%Co, 2.0%Mo, 8.0%W, 6.5%Ta, 6.1%Al, 0.15%Hf, 0.05%C, 0.004%B, 0.015%Y, the balance of Ni. The composition of the designed alloy has the following characteristics: the number of electron vacancies is 2.17; the content of refractory elements (W, Ta, Mo) is 16.5%, of which W+Mo is 10%; the content of γ′ phase-forming elements (Al, Ta) is 12.6% .

[0036] (2) Master alloy smelting

[0037]According to the mass percentage of different alloying elements obtained by (1) composition design, the required alloy is configured by using high-purity metal components. Under high vacuum conditions, the master alloy was melted in a calcium oxide crucible with a melting power of 25kW and a melting time of 15 minutes.

[0038] (3) Master alloy casting rod preparation

[0039] After the master alloy was remelted in a ...

Embodiment 2

[0052] (1) Alloy composition design

[0053] The rhenium-free nickel-based superalloy of the present invention has the following alloy components by mass percentage: 7.25%Cr, 4.8%Co, 1.8%Mo, 7.8%W, 6.3%Ta, 6.0%Al, 0.12%Hf, 0.04%C, 0.003%B, 0.010%Y, the balance of Ni. The composition of the designed alloy has the following characteristics: the number of electron vacancies is 2.07; the content of refractory elements (W, Ta, Mo) is 15.9%, of which W+Mo is 9.6%; the content of γ′ phase-forming elements (Al, Ta) is 12.5% .

[0054] (2) Master alloy smelting

[0055] According to the mass percentage of different alloying elements obtained by (1) composition design, the required alloy is configured by using high-purity metal components. Under high vacuum conditions, the master alloy was melted in a calcium oxide crucible with a melting power of 22.5kW and a melting time of 22.5 minutes.

[0056] (3) Master alloy casting rod preparation

[0057] After the master alloy was remelte...

Embodiment 3

[0063] (1) Alloy composition design

[0064] The rhenium-free nickel-based superalloy of the present invention has the following alloy components by mass percentage: 7.75%Cr, 5.2%Co, 2.2%Mo, 8.2%W, 6.7%Ta, 6.2%Al, 0.18%Hf, 0.06%C, 0.005%B, 0.03%Y, the balance of Ni. The composition of the designed alloy has the following characteristics: the number of electron vacancies is 2.30; the content of refractory elements (W, Ta, Mo) is 17.1%, of which W+Mo is 10.4%; the content of γ′ phase forming elements (Al, Ta) is 12.7% .

[0065] (2) Master alloy smelting

[0066] According to the mass percentage of different alloying elements obtained by (1) composition design, the required alloy is configured by using high-purity metal components. Under high vacuum conditions, the master alloy was melted in a calcium oxide crucible with a melting power of 20kW and a melting time of 30 minutes.

[0067] (3) Master alloy casting rod preparation

[0068] After the master alloy was remelted in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com