Method for preparing cobalt/graphene composite material by alcohol thermal method

A technology of composite materials and graphene, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of many process steps and high cost, and achieve simple process, good crystallinity and dispersibility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

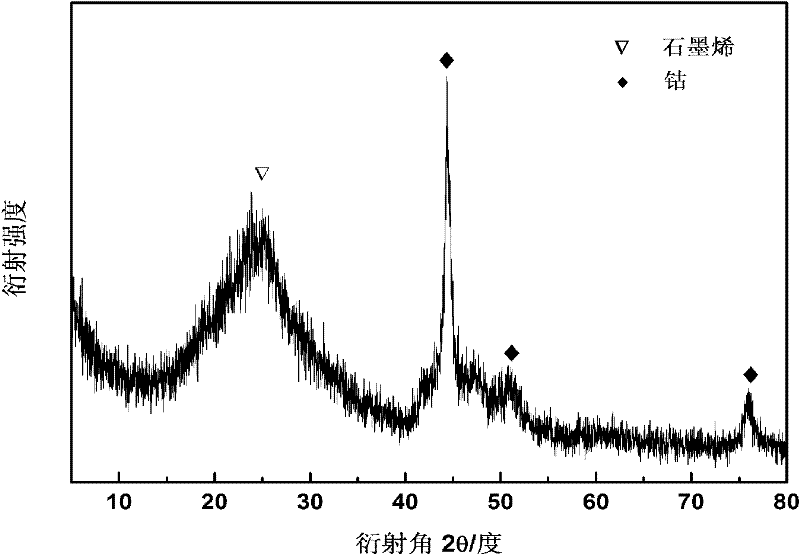

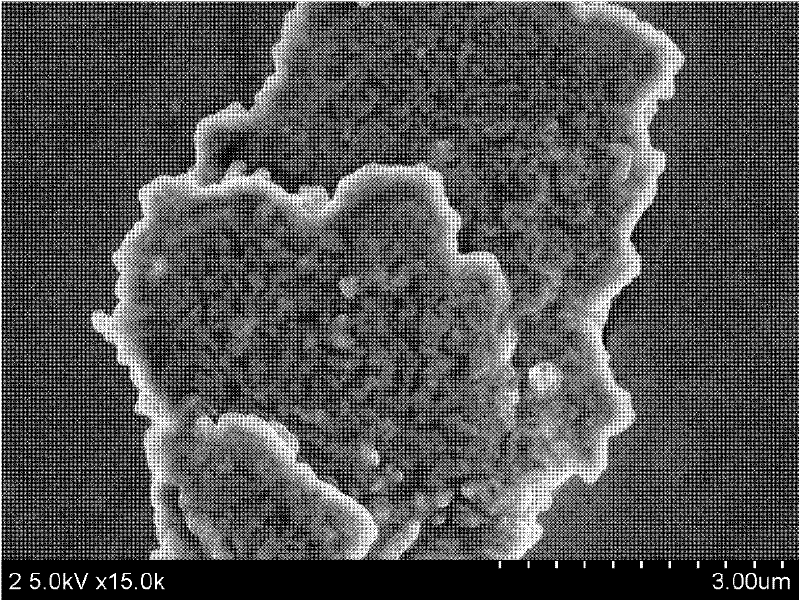

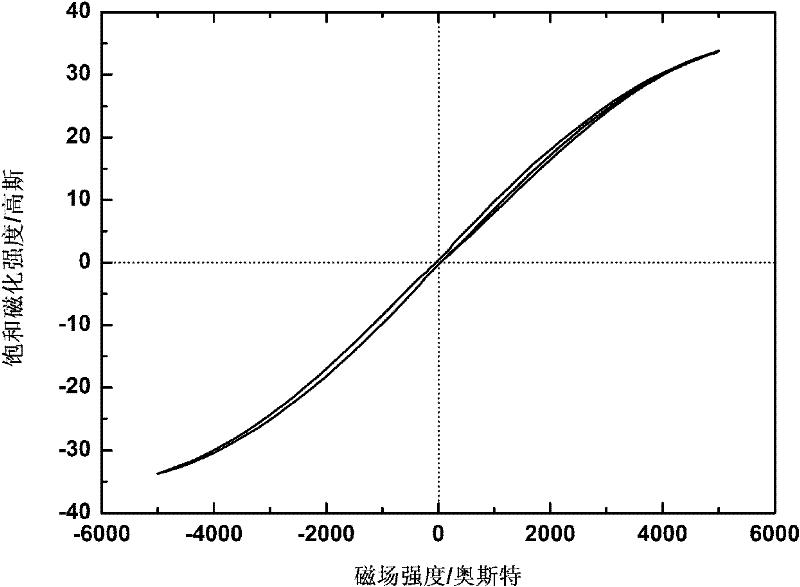

[0025] Weigh 55mg of graphite oxide and disperse in 28mL of ethylene glycol solution at room temperature. After the resulting mixture is ultrasonically dispersed for 45min, add 110mg of cobalt nitrate, 1200mg of anhydrous sodium acetate and 0.2mL of polyethylene glycol 200, and stir for 1.5h to form a reaction solution . The reaction solution was added into the reaction kettle, the temperature was raised to 200°C, and the reaction was carried out for 12 hours. After the reaction was completed, the product was collected by centrifugation, washed 6 times with deionized water and 3 times with absolute ethanol, and then dried at 60° C. for 18 hours to obtain a cobalt / graphene composite material. figure 1 The X-ray diffraction pattern of the material obtained in this example shows that the nanoparticles in the composite material are cobalt, and the graphite oxide is reduced to graphene. figure 2 It is a scanning electron microscope photo of the material obtained in this embodime...

Embodiment 2

[0027] Weigh 55 mg of graphite oxide and disperse in 110 mL of ethylene glycol solution at room temperature. After the resulting mixture is ultrasonically dispersed for 30 min, add 55 mg of cobalt nitrate, 550 mg of anhydrous sodium acetate and 1 mL of polyethylene glycol 1000, and stir for 1 h to form a reaction solution. The reaction solution was added to the reaction kettle, the temperature was raised to 180°C, and the reaction was carried out for 16 hours. After the reaction was completed, the product was collected by centrifugation, washed 8 times with deionized water and 5 times with absolute ethanol, and then dried at 40° C. for 24 h to obtain a cobalt / graphene composite material. X-ray diffraction analysis shows that the nanoparticles in the synthesized material of this example are cobalt. The hysteresis loop test shows that the obtained material has good magnetic properties. The resistivity test results show that the composite material has good electrical conductivit...

Embodiment 3

[0029] Weigh 55 mg of graphite oxide and disperse in 55 mL of ethylene glycol solution at room temperature. After ultrasonic dispersion of the resulting mixture for 60 min, add 165 mg of cobalt nitrate, 1980 mg of anhydrous sodium acetate and 0.1 mL of polyethylene glycol 400, and stir for 2 h to form a reaction solution. The reaction solution was added into the reaction kettle, the temperature was raised to 210°C, and the reaction was carried out for 8 hours. After the reaction was completed, the product was collected by centrifugation, washed with deionized water and absolute ethanol, and then dried at 80° C. for 12 hours to obtain a cobalt / graphene composite material. X-ray diffraction analysis shows that the nanoparticles in the synthesized material of this example are cobalt. The hysteresis loop test shows that the obtained material has good magnetic properties. The resistivity test results show that the composite material has good electrical conductivity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com