Large-scale domestic garbage pyrolysis and gasification technology

A technology of pyrolysis gasification and domestic waste, applied in the field of domestic waste pyrolysis gasification technology, can solve the problems of long process flow, low overall calorific value, high equipment requirements, etc., achieve simple charging process, solve environmental protection problems, and protect the environment good protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

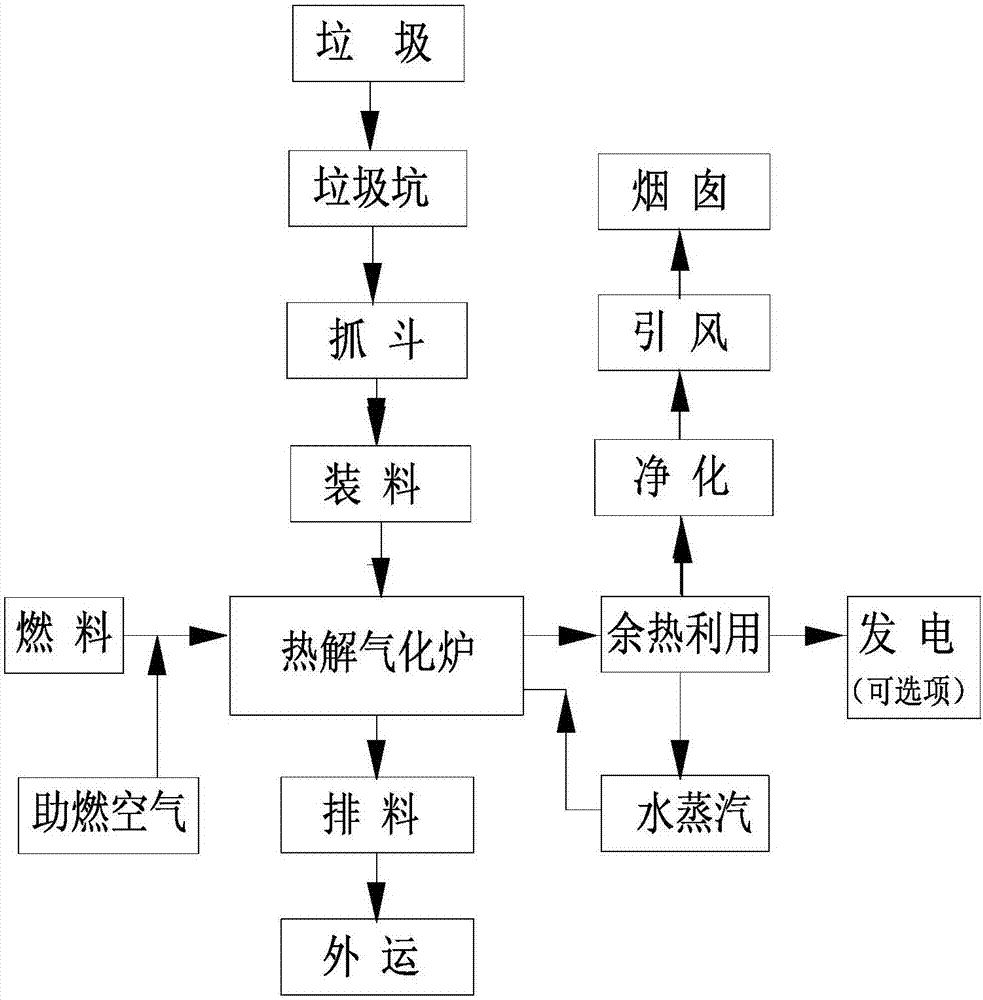

[0039] Such as figure 1 As shown, the present invention provides a kind of household garbage pyrolysis gasification process suitable for townships, small towns or remote areas, and its main production steps include:

[0040] 1) Household garbage is transported to the garbage pit and piled up. If it is a large combustible garbage, it needs to be crushed and put into the garbage pit. The length, width and height of a single piece of garbage should be less than 500x500x500mm;

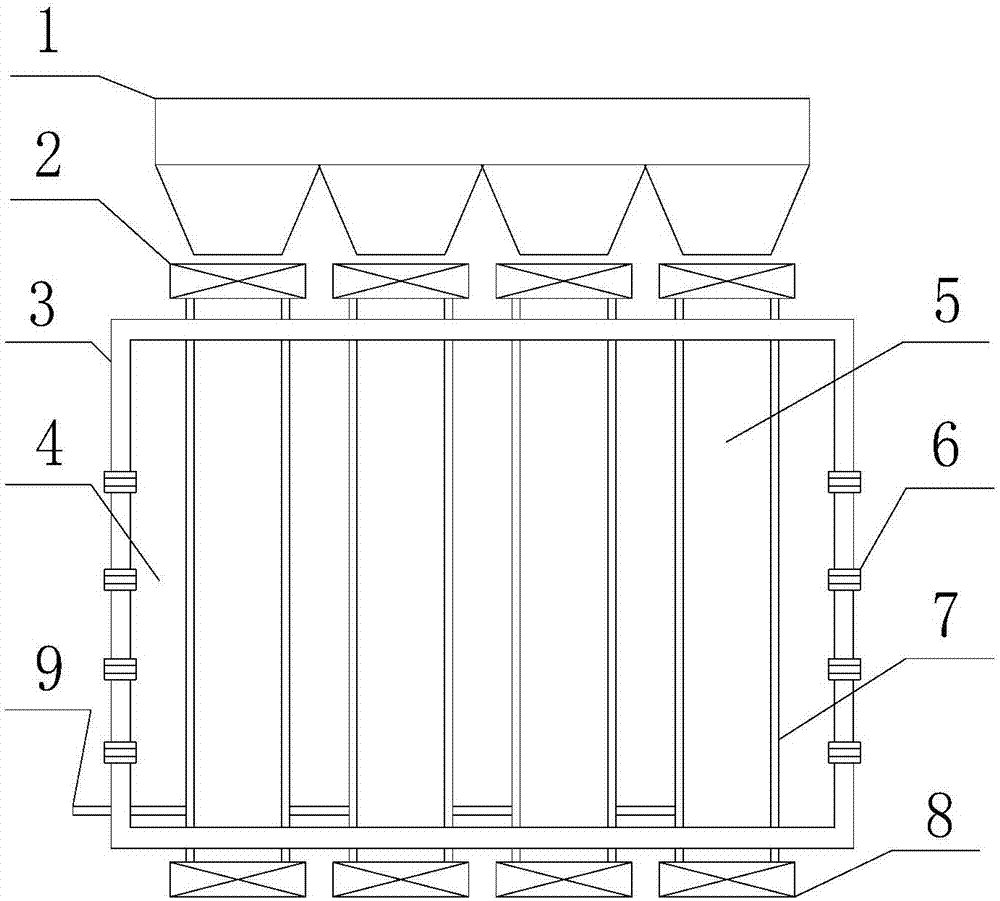

[0041] 2) Grab 1 ton of domestic waste to the top of the pyrolysis gasification furnace with a 1t grab bucket, put it into the pyrolysis gasification tank in the pyrolysis gasification furnace through the receiving tank, and then close the pyrolysis gas with a sealing valve the top of the tank;

[0042] 3) Two pyrolysis gasification tanks are arranged in one combustion chamber. The temperature in the combustion chamber is 1100°C, and the temperature in the pyrolysis gasification tank is 950°C. The fuel i...

Embodiment 2

[0053] Such as figure 1 As shown, the present invention provides a kind of domestic garbage pyrolysis gasification process suitable for large cities, and its main production steps include:

[0054] 1) Household garbage is transported to the garbage pit and piled up. If it is a large combustible garbage, it needs to be crushed and put into the garbage pit. The length, width and height of a single piece of garbage should be less than 500x500x500mm;

[0055] 2) Grab 2t of domestic garbage to the top of the pyrolysis gasification furnace with five 2t grab buckets, put it into the pyrolysis gasification tank in the pyrolysis gasification furnace through the receiving tank, and then close the pyrolysis gas with a sealing valve the top of the tank;

[0056] 3) 66 pyrolysis gasification tanks are arranged in one combustion chamber. The temperature in the combustion chamber is 1100°C, and the temperature inside the pyrolysis gasification tank is 950°C. Gas produced by degasification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com