Method for synthesizing zeolite ZSM-48

A technology of ZSM-48 and zeolite, applied in the field of hydrothermal synthesis of ZSM-48 zeolite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

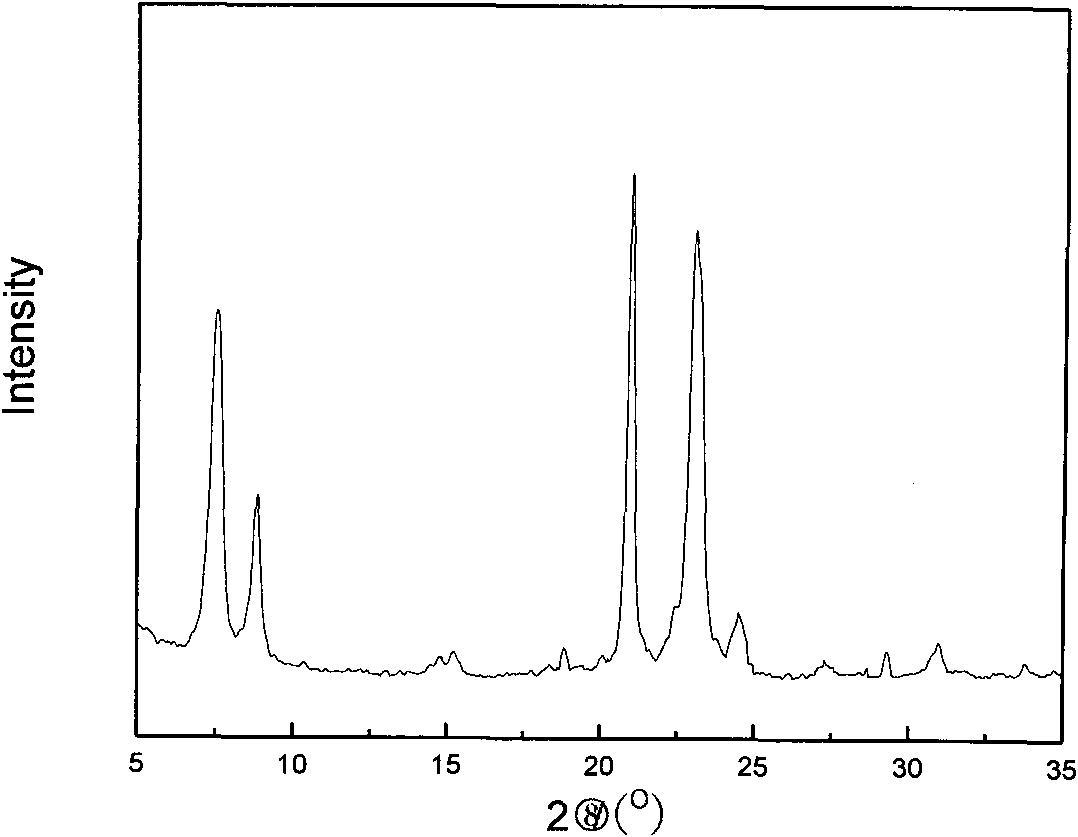

Embodiment approach 1

[0025] I, structure directing agent N, the preparation of N-diethylhexamethyleneimine quaternary ammonium base

[0026] Into a 250 ml three-necked flask equipped with a stirrer, a reflux condenser and a dropping funnel, 39.6 g (0.4 mol) of hexamethyleneimine (hexamethyleneimine) and 60 ml of water were added. Heating with a water bath kept the reaction mixture at about 35° C., and added 21.8 g (0.2 mol) of bromoethane dropwise under stirring. After the addition, the stirring was continued for 8 hours at about 35°C. After cooling, the upper organic phase was separated, dried overnight with solid potassium hydroxide, and then distilled to collect fractions at 147-149° C. to obtain 20.3 g (0.16 moles) of N-ethylhexamethyleneimine. After confirming its chemical structure by NMR spectrum, IR spectrum and elemental analysis, 20.3g (0.16 mole) N-ethylhexamethyleneimine was dissolved in 60 milliliters of acetone, and excess bromoethane (26.2g 0.24 mole) was added , stirred at room t...

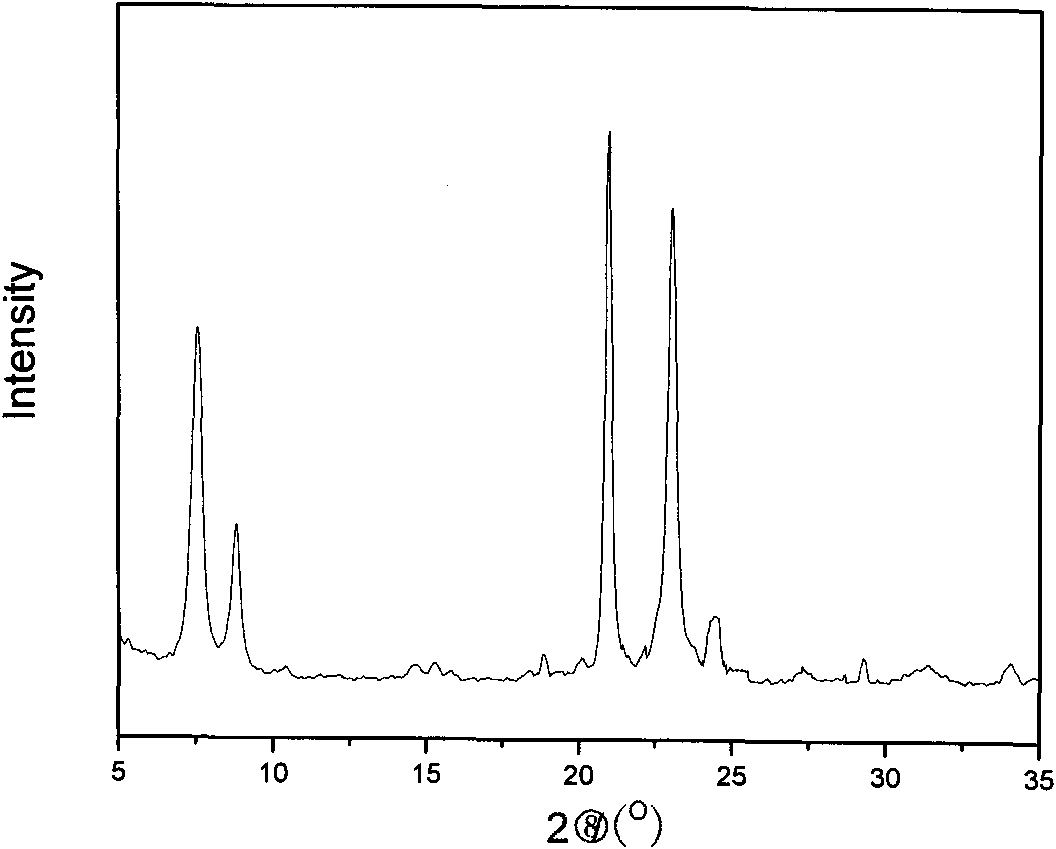

Embodiment approach 2

[0030] I, structure directing agent N, the preparation of N-diethylhexamethyleneimine quaternary ammonium base

[0031] Into a 250 ml three-necked flask equipped with a stirrer, a reflux condenser and a dropping funnel, 49.5 g (0.5 mol) of hexamethyleneimine (hexamethyleneimine) and 80 ml of water were added. Heating with a water bath kept the reaction mixture at about 30°C, and added 23.98 g (0.22 moles) of bromoethane dropwise under stirring. After the addition, the stirring was continued for 10 hours at about 30°C. After cooling, the upper organic phase was separated, dried overnight with solid potassium hydroxide, and then distilled to collect fractions at 147-149°C to obtain 22.8 g (0.18 moles) of N-ethylhexamethyleneimine. After confirming its chemical structure by NMR spectrum, IR spectrum and elemental analysis, 22.8g (0.18 moles) of N-ethylhexamethyleneimine was dissolved in 50 milliliters of acetone, and excess bromoethane (28.3g 0.26 moles) was added , stirred at ro...

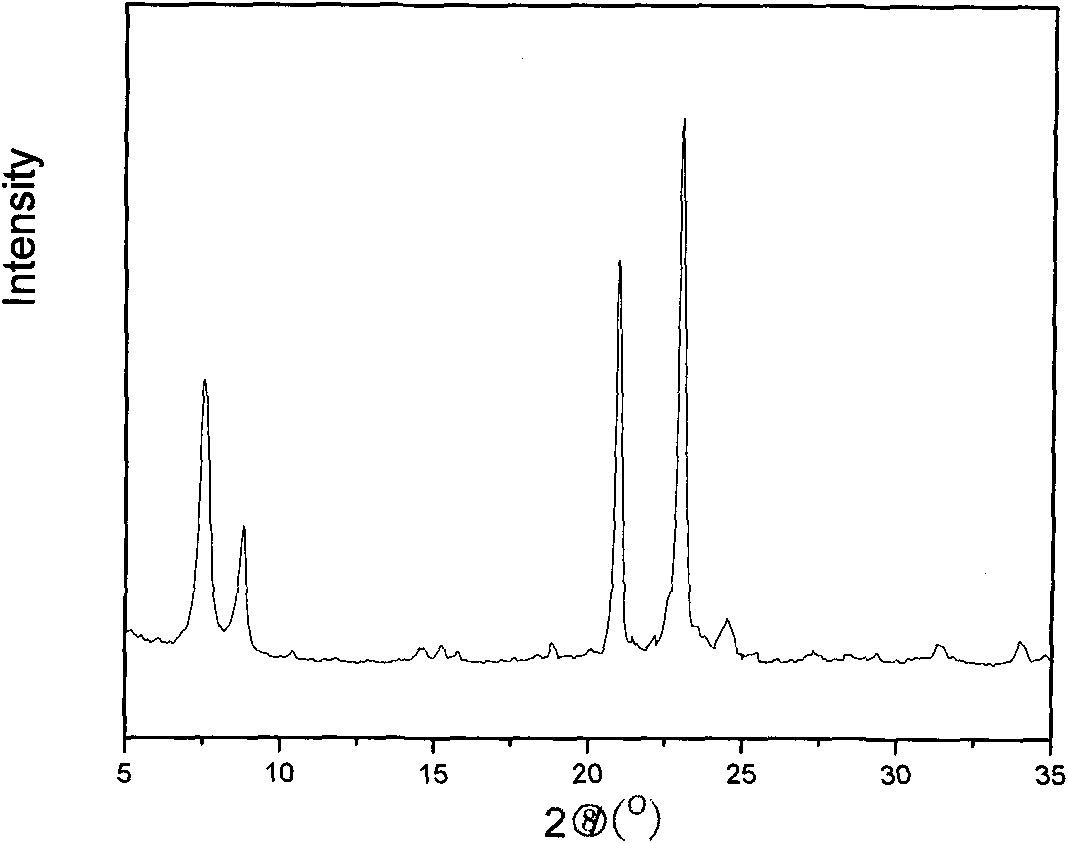

Embodiment approach 3

[0035] I, structure directing agent N, the preparation of N-diethylhexamethyleneimine quaternary ammonium base

[0036] Into a 500 ml three-necked flask equipped with a stirrer, a reflux condenser and a dropping funnel, 99.0 g (1.0 mol) of hexamethyleneimine (hexamethyleneimine) and 200 ml of water were added. Heating with a water bath kept the reaction mixture at about 25°C, and added 49.1 g (0.45 mol) of bromoethane dropwise under stirring. After the addition was complete, stirring was continued for 16 hours at about 25°C. After cooling, the upper organic phase was separated, dried overnight with solid potassium hydroxide, and then distilled to collect fractions at 147-149°C to obtain 48.2 g (0.38 moles) of N-ethylhexamethyleneimine. After confirming its chemical structure by NMR spectrum, IR spectrum and elemental analysis, 48.2g (0.38 moles) of N-ethylhexamethyleneimine was dissolved in 120 milliliters of acetone, and excess bromoethane (54.5g 0.5 moles) was added , stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com