Pyrolyzing and melting kiln and method for preparing ceramics and fuel oil by pyrolyzing garbage

A pyrolysis furnace and pyrolysis technology, applied in the direction of combustion methods, ceramic material production, lighting and heating equipment, etc., can solve the problems of large heat loss, low commercial value, large investment scale, etc., to reduce NOx emissions, The effect of reducing investment and operating costs and improving thermal energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

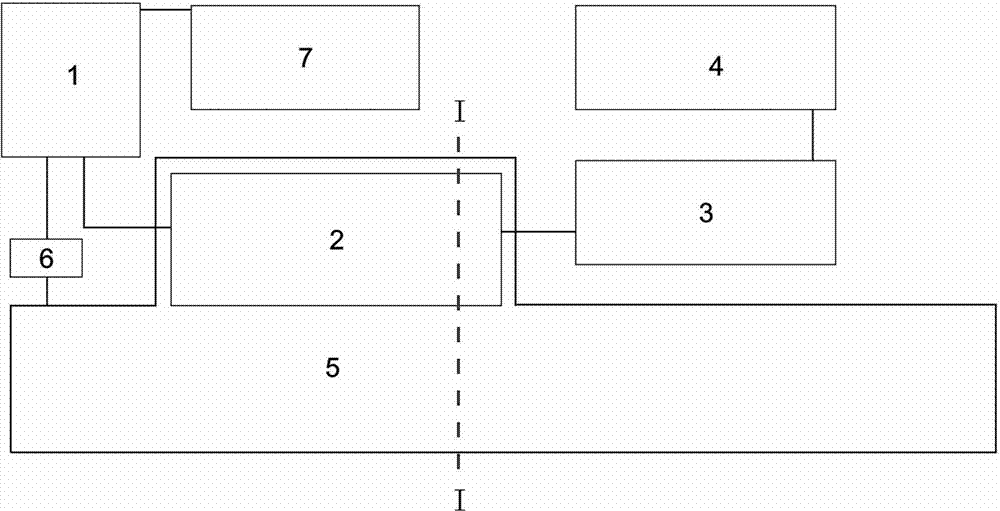

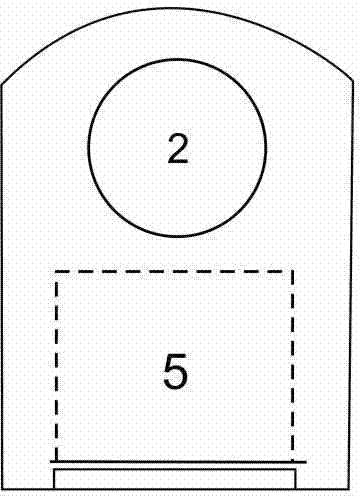

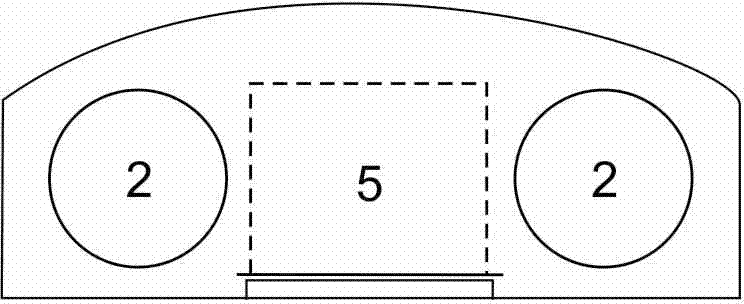

[0031] Embodiment 1: with reference to attached figure 1 and 4 , This example is a designed pyrolysis melting furnace with 3 pyrolysis cylinders. The method is to enclose a cavity with heat-resisting refractory walls, and set up three pyrolysis cylinders 2 and a material carrying and transferring device 5 inside. On both sides of the material carrying and transferring device 5; the air inlet at the lower part of the vertical garbage drying heat shrinker 1 is connected with the exhaust fan 6, the gas outlet at the upper part is connected with the flue gas purifier 7, and the blanking port at the lower part is respectively connected with 3 The feeder at the front end of the pyrolysis cylinder 2 is connected, and the rear end of the pyrolysis cylinder 2 is equipped with the slagging device and the exhaust pipe, and the exhaust pipe is connected to the condenser 3, which is then connected to the oil and gas storage device 4 connected. The pyrolysis furnace cavity and the tunnel...

Embodiment 2

[0032] Embodiment 2: with reference to attached figure 1 and 3 , This example is a refitted pyrolysis melting furnace with 2 pyrolysis cylinders. The method is to place two horizontal external thermal pyrolysis furnaces adjacent to the middle and low temperature sections of the tunnel kiln, part or all of the adjacent furnace walls and kiln walls are removed, and the cross-sections are connected and sealed with similar heat-insulating refractory materials, so that The furnace cavity of the pyrolysis furnace and the same temperature section of the kiln cavity of the tunnel kiln communicate with each other; other parts of the equipment are the same as in Embodiment 1. The basis for the modification (including design) is to place the high-temperature end of the tail of the pyrolysis cylinder adjacent to the kiln chamber at the same temperature as the tunnel kiln according to the maximum temperature of the pyrolysis of mixed waste, and adjust the length and diameter of the pyroly...

Embodiment 3

[0033] Embodiment 3: with reference to attached Figure 5 , This example is the method of using the pyrolysis melting furnace described in Example 1 to pyrolyze garbage to prepare ceramics and fuel oil. The bag-broken and crushed mixed garbage falls into the vertical drying heat shrinker 1, and meets the hot air and flue gas sucked by the exhaust fan 6 from the kiln cavity with a temperature lower than 200°C, and the garbage moves downward to complete water evaporation and thermal shrinkage During the process, the flue gas falls into the feeder, the waste heat of the flue gas is fully utilized and initially purified by the adsorption of the material, the evaporated water together with the flue gas enters the flue gas purifier 7 for purification and discharge, and the dry and heat-shrinkable garbage falls to the The feeder, and the re-material sealed oxygen are respectively pressed into the three pyrolysis cylinders 2, and the garbage is cracked by heat and anoxic in the cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com