Anti-yellowing polyamide composition and preparation method of anti-yellowing polyamide

A polyamide composition and a technology for yellowing resistance, applied in the field of polymer materials, can solve the problems of reduced mechanical properties of polymer materials, unsatisfactory long-term light aging resistance, etc. yellowing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042]

[0043] The preparation method of the anti-yellowing polyamide comprises the steps of: melting and mixing the components of the above-mentioned anti-yellowing polyamide composition to obtain the anti-yellowing polyamide; the components of the anti-yellowing polyamide composition include polyamide 56 and anti-yellowing polyamide Aging agent, anti-aging agent includes heat stabilizer, light stabilizer and amino functional group blocking agent.

[0044] The method of above-mentioned melt mixing can be one-time adding method, also can be batch-wise adding method.

[0045] The one-time addition method refers to adding polyamide 56 (as a polymer component), a heat stabilizer (as a non-polymer component), a light stabilizer (as a non-polymer component) and an amino functional group capping agent (as a non-polymer component) ) etc. are all added to a melt mixer, single-screw extruder, twin-screw extruder, agitator, single-screw kneader, twin-screw kneader or Banbury mixer at...

Embodiment 1-4 and comparative example 1

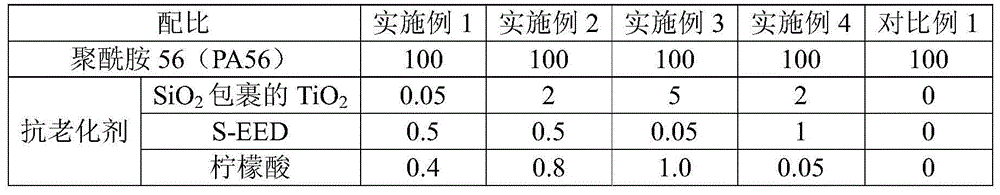

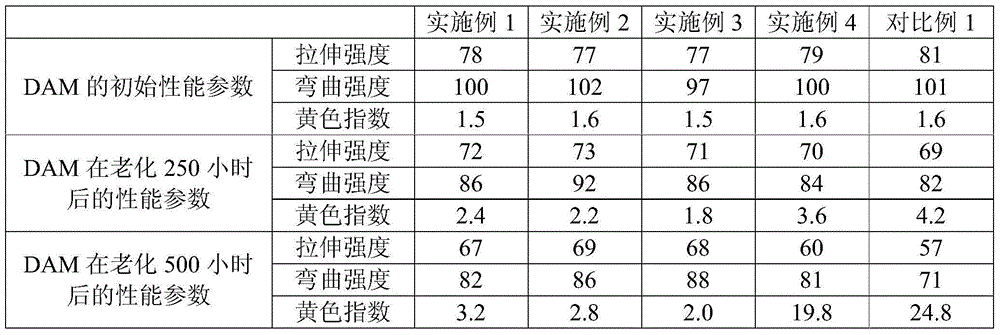

[0063] The ingredients and contents of the compositions in Examples 1-4 and Comparative Example 1 are shown in Table 1.

[0064] Composition and content thereof in Table 1 embodiment 1-4 and comparative example 1

[0065]

[0066] The preparation method of the anti-yellowing polyamide in embodiment 1 to 4 and comparative example 1 is as follows:

[0067] According to the ratio shown in Table 1, polyamide 56 is supplied from the top feed port to the SK40mm twin-screw extruder manufactured by Keya. The operating temperature is about 280°C, the melting temperature is 290°C, and the screw speed is about 300rpm. Production The capacity is 40kg / h, and then according to the ratio shown in Table 1, add anti-aging agent from the side feed port, cool the melted kneaded product extruded from the die outlet in the form of strands, and pelletize to obtain polyamide Composition granules. The polyamide 56 and the anti-aging agent can be added at one time or in batches.

[0068] The pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com