Method for preparing zinc oxide (ZnO) nanorods

A nanorod, zinc oxide technology, applied in the direction of zinc oxide/zinc hydroxide, etc., achieves the effects of not easy to generate, uniform size, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

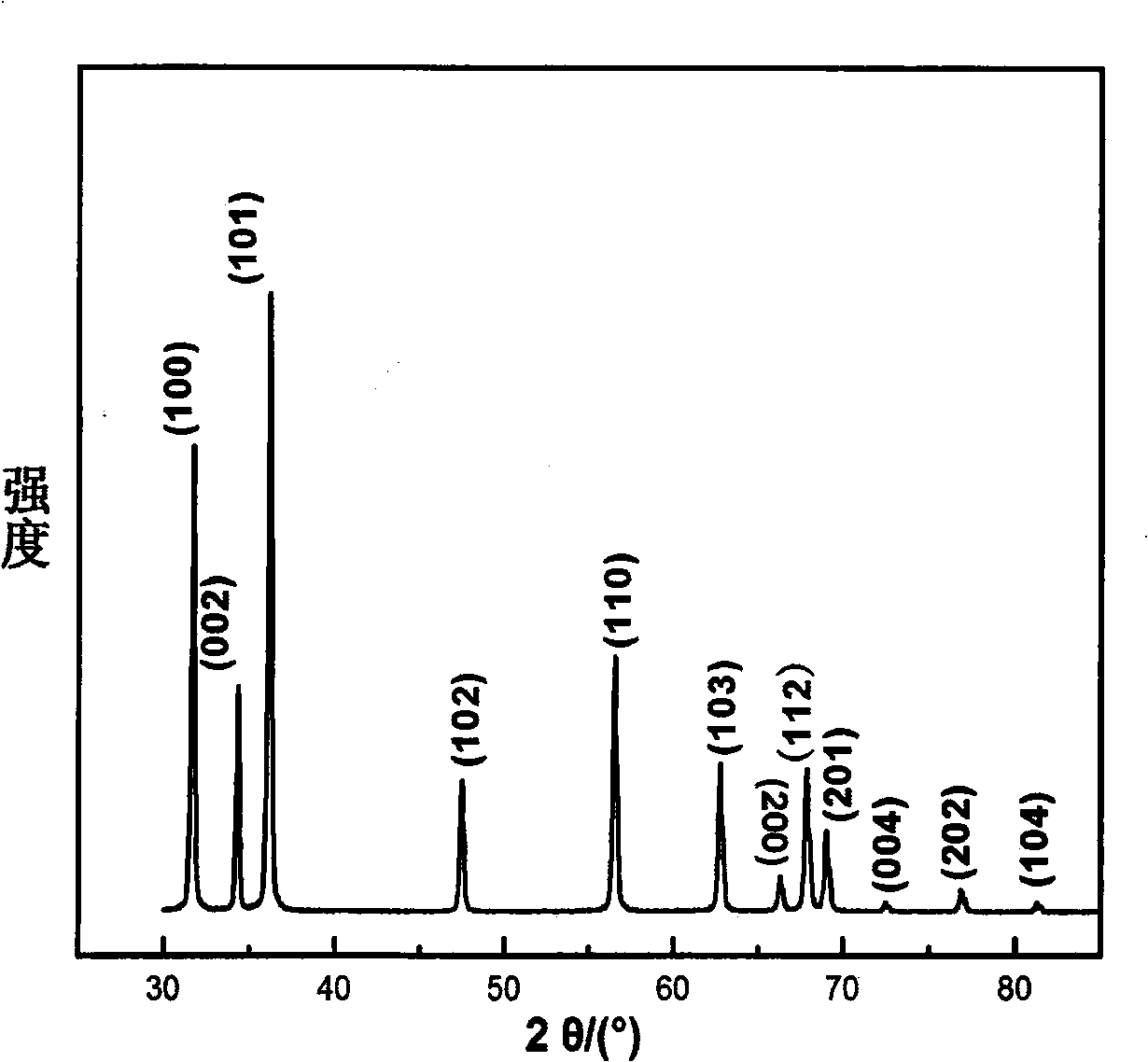

[0024] Weigh 1.0976g Zn(CH 3 COO) 2 2H 2 O. 1.1222g KOH is put into a beaker, then measure 15ml of deionized water and add it to the beaker, mechanically stir at a speed of 500 rpm for 20 minutes, then measure 30ml of a mixture of ethylenediamine and ethanolamine with a volume ratio of 1:1 The solvent was added into a beaker, and mechanically stirred at 500 rpm for 40 minutes to obtain a clear reaction solution; the above reaction solution was poured into a reaction kettle, put into an oven, heated to 110°C, and reacted for 10 hours. After the reaction was completed, it was naturally cooled to room temperature. The product was obtained by centrifugation at 6000 rpm for 15 minutes; the product was washed with deionized water and absolute ethanol three times respectively, and then dried at 60° C. for 5 hours to obtain ZnO nanorod powder. figure 1 For the X-ray diffraction pattern of the powder synthesized in this example, the comparison standard XRD spectrum shows that the n...

Embodiment 2

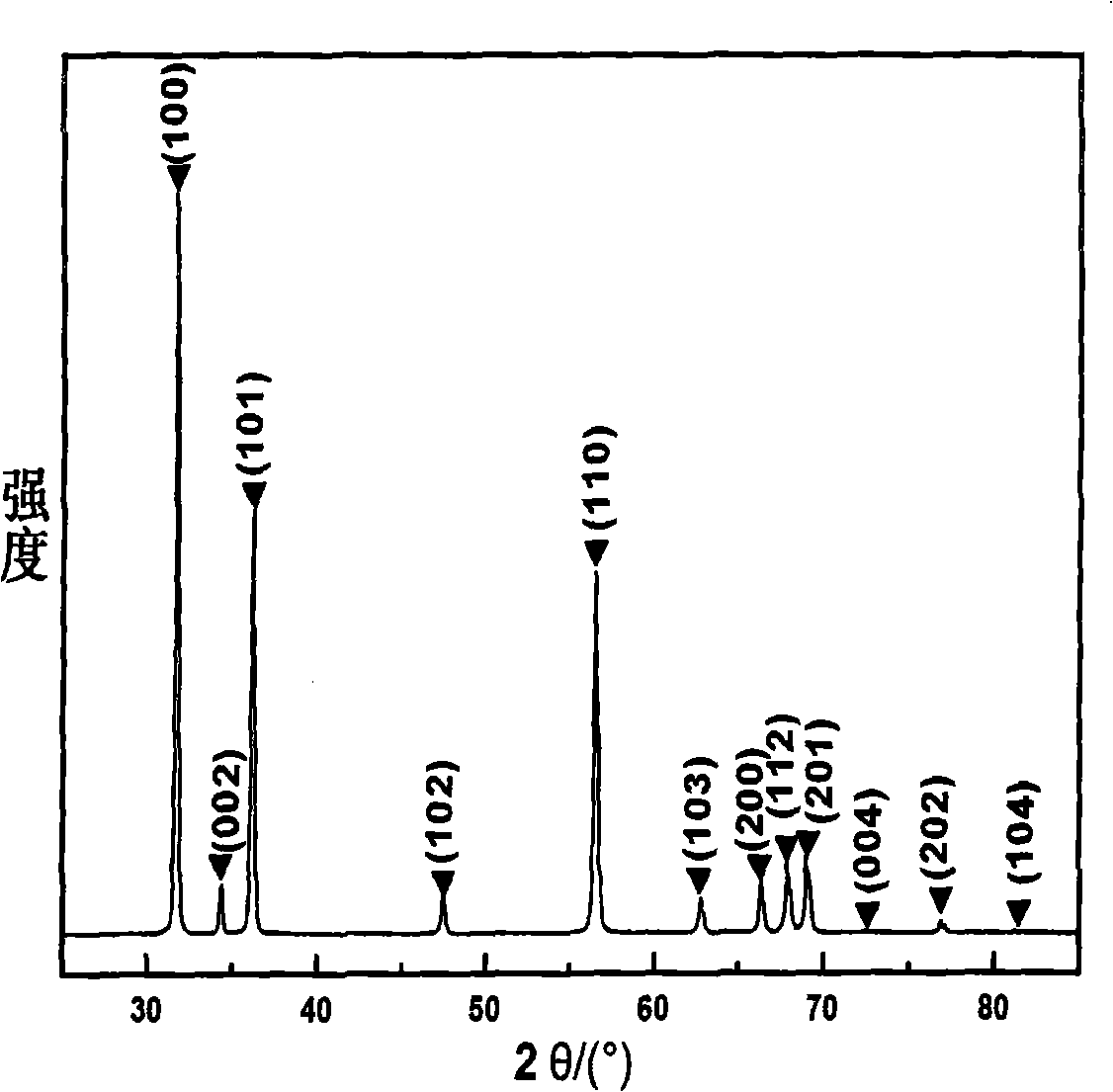

[0026] Weigh 1.0976g Zn(CH 3 COO) 2 2H 2 O. 0.8417g KOH is put into the beaker, then measure 30ml of deionized water and add it into the beaker, mechanically stir at 800 rpm for 10 minutes, then measure 20ml of the mixture of ethylenediamine and ethanolamine with a volume ratio of 5:1 The solvent was added into a beaker, and mechanically stirred at 800 rpm for 20 minutes to obtain a clear reaction solution; the above reaction solution was poured into a reaction kettle, placed in an oven, heated to 120°C, and reacted for 8 hours. After the reaction was completed, it was naturally cooled to room temperature. The product was obtained by centrifugation at 8000 rpm for 5 minutes; the product was washed with deionized water for 6 times, washed with absolute ethanol once, and then dried at 40°C for 12 hours to obtain ZnO nanopowder. image 3 The X-ray diffraction pattern of the powder synthesized in this example is compared with the standard XRD pattern, which shows that the nano-...

Embodiment 3

[0028] Weigh 1.0976g Zn(CH 3 COO) 2 2H 2 0. 0.5611gKOH is put into the beaker, then measure 10ml of deionized water and add it to the beaker, mechanically stir at a speed of 700 rpm for 15 minutes, then measure 20ml of a mixed solvent with a volume ratio of 1:5 ethylenediamine and ethanolamine In a beaker, stir mechanically at 700 rpm for 25 minutes to obtain a clear reaction solution; pour the above reaction solution into a reaction kettle, put it in an oven, heat up to 120° C., and react for 6 hours. After the reaction was completed, it was naturally cooled to room temperature. The product was obtained by centrifugation at 7000 rpm for 8 minutes; the product was washed 4 times with deionized water and 2 times with absolute ethanol, and then dried at 50° C. for 10 hours to obtain ZnO nanopowder. Figure 4 The X-ray diffraction pattern of the powder synthesized in this example is compared with the standard XRD pattern, which shows that the nano-powder is ZnO in the hexagona...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com