Device for simultaneous growth of multiple silicon carbide single crystals

A silicon carbide single crystal, one-way valve technology, applied in the direction of single crystal growth, single crystal growth, polycrystalline material growth, etc., can solve the problems of harsh growth conditions, low production efficiency, long growth time, etc., to achieve adjustment and Accurate and reliable control, precise and controllable effect of adjusting the growth atmosphere

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the embodiments of the present invention.

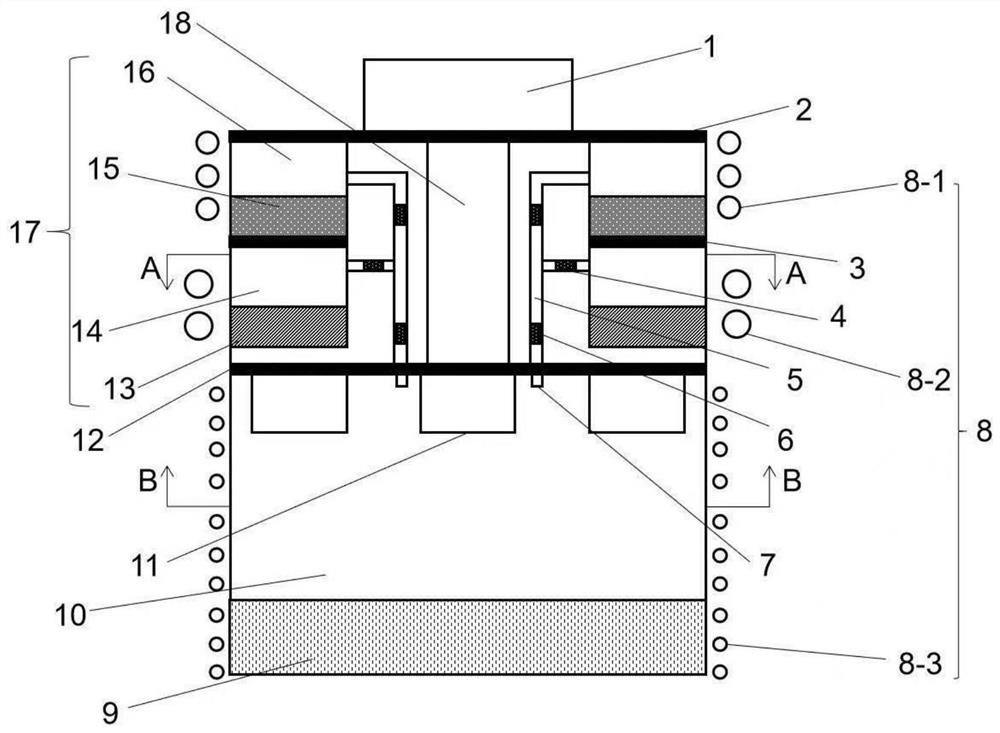

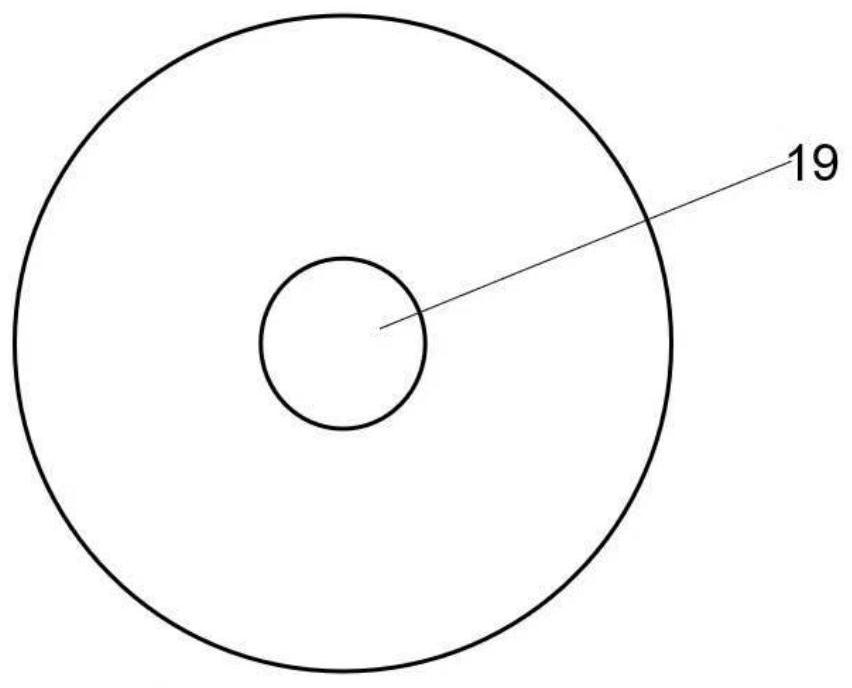

[0026] refer to Figure 1 to Figure 8 , the present invention is a device for simultaneous growth of multiple silicon carbide single crystals, comprising a graphite crucible 21, an induction heating coil 8 and a driving mechanism 1; the driving mechanism 1 is located above the outside of the graphite crucible 21, and the induction heating The coil 8 is located outside the graphite crucible 21; the graphite crucible 21 includes a main chamber 10 located at the bottom and an auxiliary chamber 17 located at the top, the bottom of the main chamber 10 contains silicon carbide source powder 9, and the auxiliary chamber 17 Comprising a first auxiliary material tank 16 and a second auxiliary material tank 14, the bottom of the first auxiliary material tank 14 holds silicon carbide source powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com