Control method of intelligent cigarette cavity heating control system for lower-temperature cigarette

A heating control and control method technology, applied in the field of electronic cigarettes, can solve the problems of wasting shredded tobacco, unable to make full use of shredded tobacco, etc., and achieve the effect of easy shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

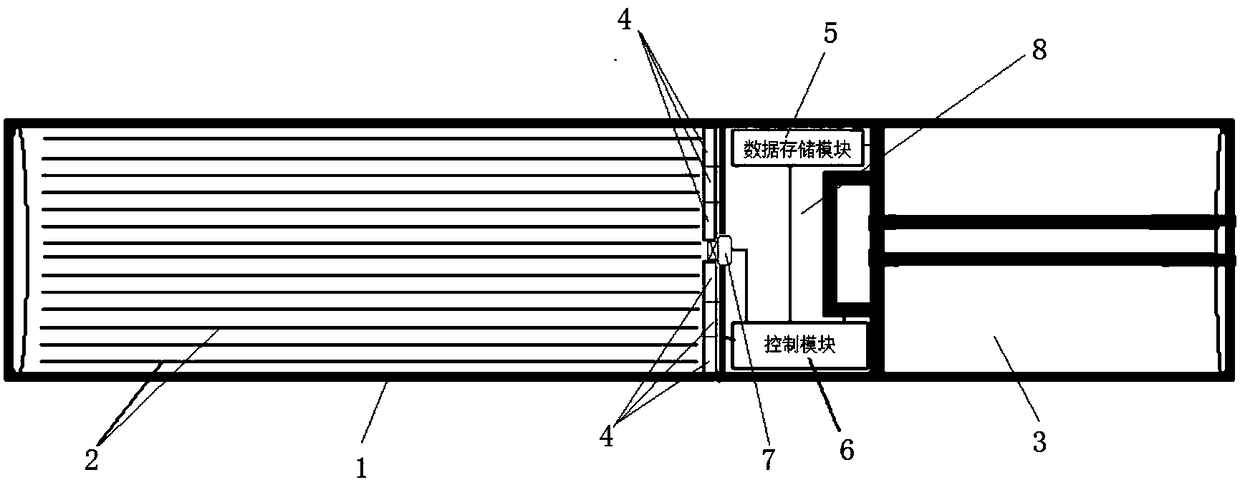

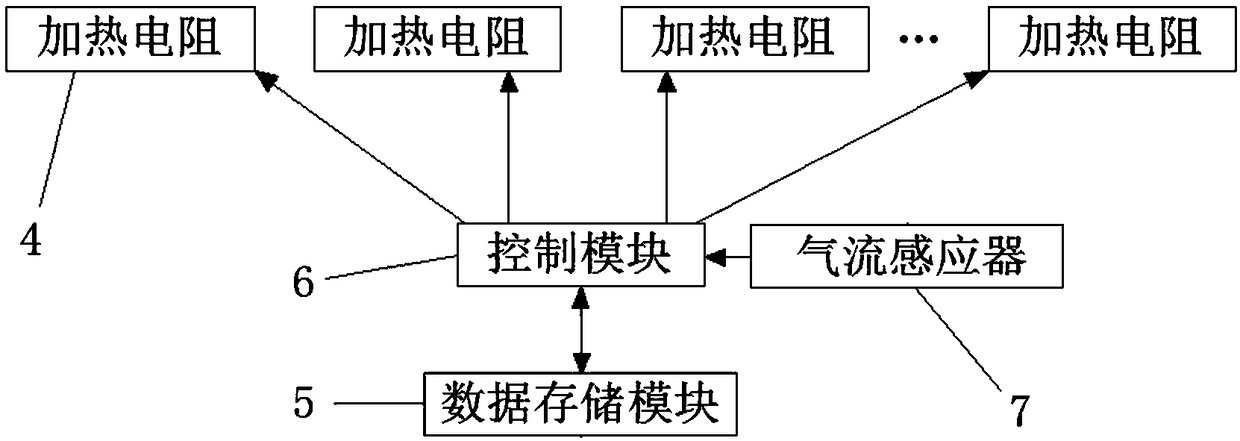

Embodiment 1

[0034] In this embodiment, the heating resistor 4 is a fan-shaped plate, which is arranged in a circle along the circumference of the smoke cavity 1 and installed at the bottom of the smoke cavity 1. Compared with Example 1, the number of heating resistors 4 is smaller, and the shape is easy to assemble, but the corresponding control of the heating speed is relatively rough, because a fan-shaped heating resistor 4 has been provided with more heating needles 2.

Embodiment 2

[0036] In this embodiment, the heating resistor 4 is a strip-shaped plate, which is arranged in several layers ring-shaped and installed at the bottom of the smoke chamber 1 with the center of the smoke chamber 1 as the center. Compared with Example 1, the heating resistor 4 of the strip-shaped plate is used. The smoke cavity 1 of the same cross-section requires a larger number of heating resistors. However, it is also possible to perform more detailed heating speed control, which can further reduce the tobacco and electric energy. waste.

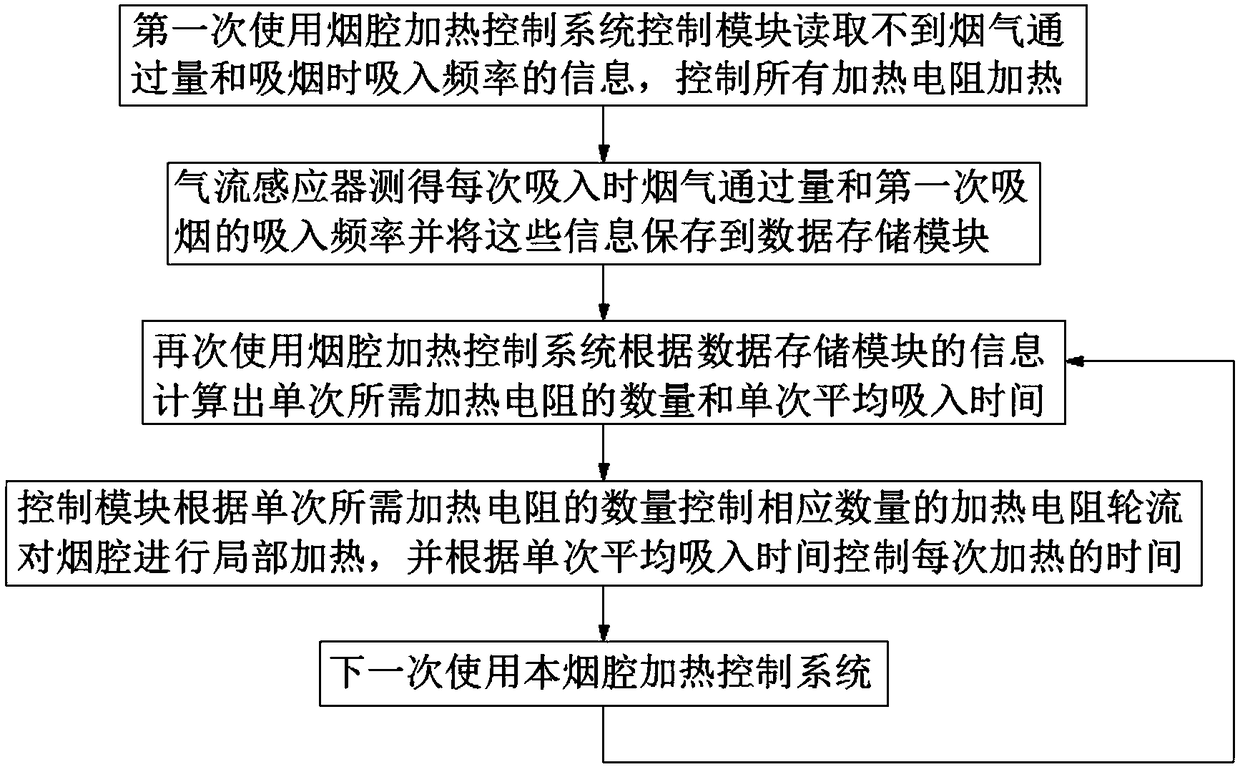

[0037] S1. Turn on the switch for the first time to use the smoke cavity heating control system. The control module 6 cannot read the information about the amount of smoke and the frequency of inhalation during smoking, and controls the heating of all heating resistors 4;

[0038] S2. The airflow sensor 7 detects the amount of smoke passing each time and sends the generated information to the control module 6. The control module 6 can obtain the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com