Direct heating type constant-temperature dryer

A constant temperature drying and direct heating technology, which is applied in the field of dryers, can solve the problems of low heating efficiency of circulating fans, poor structure and technical performance, and inability to meet equipment matching requirements, so as to improve work efficiency, simple structure, Fast heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

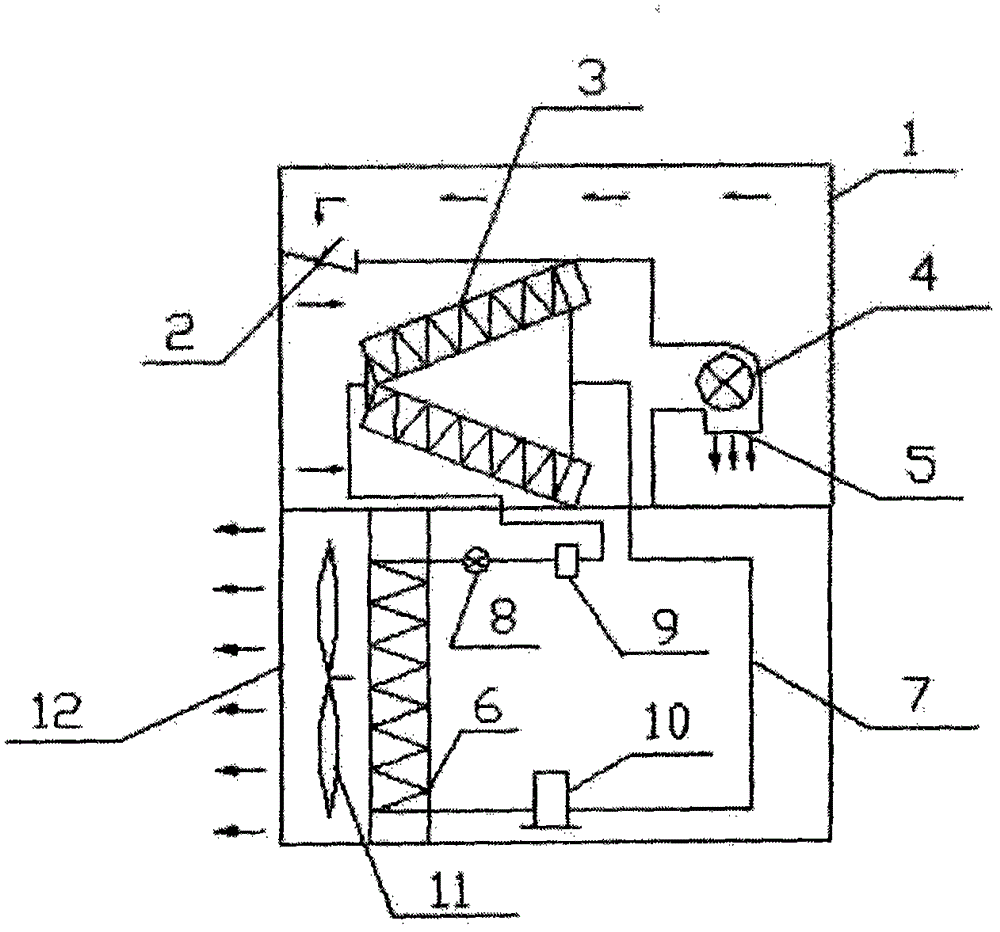

[0009] In this example, refer to figure 1 As shown, a direct heating constant temperature dryer includes an air inlet 1, an electric regulating valve 2 arranged at the end of the air inlet 1, a condenser 3 arranged at the lower right corner of the electric regulating valve 2, and a condenser 3 the centrifugal fan 4 on the right side, and the air outlet 5 arranged under the centrifugal fan 4, and the evaporator 6 arranged under the condenser 3, and the circulation delivery pipe 7 respectively connecting the two ends of the condenser 3 and the evaporator 6, and The fan 11 arranged on the left side of the condenser 3, and the moisture outlet 12 arranged on the left side of the fan 11: the condenser 3 is provided with two, and the two condensers 3 are arranged obliquely in a "<" shape, Increase the heating area for the wind to achieve fast heating speed and good heating effect, so as to achieve energy saving effect and improve the working efficiency ratio of the host.

[0010] Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com