Plant illumination system based on laser pulse

A lighting system and laser pulse technology, applied in botany equipment and methods, horticulture, horticultural methods, etc., can solve the problems of inaccurate plant light intensity and angle, affect the better growth of plants, and unfavorable cultivation of plant quality, etc., to meet the requirements of Light requirements, good growth, and sunburn prevention effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

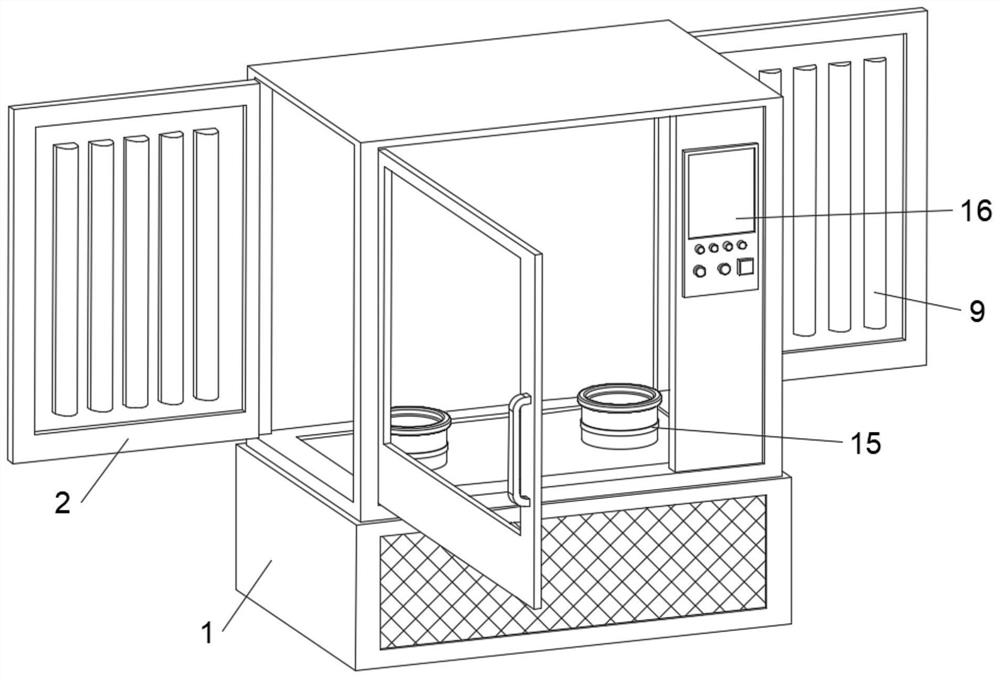

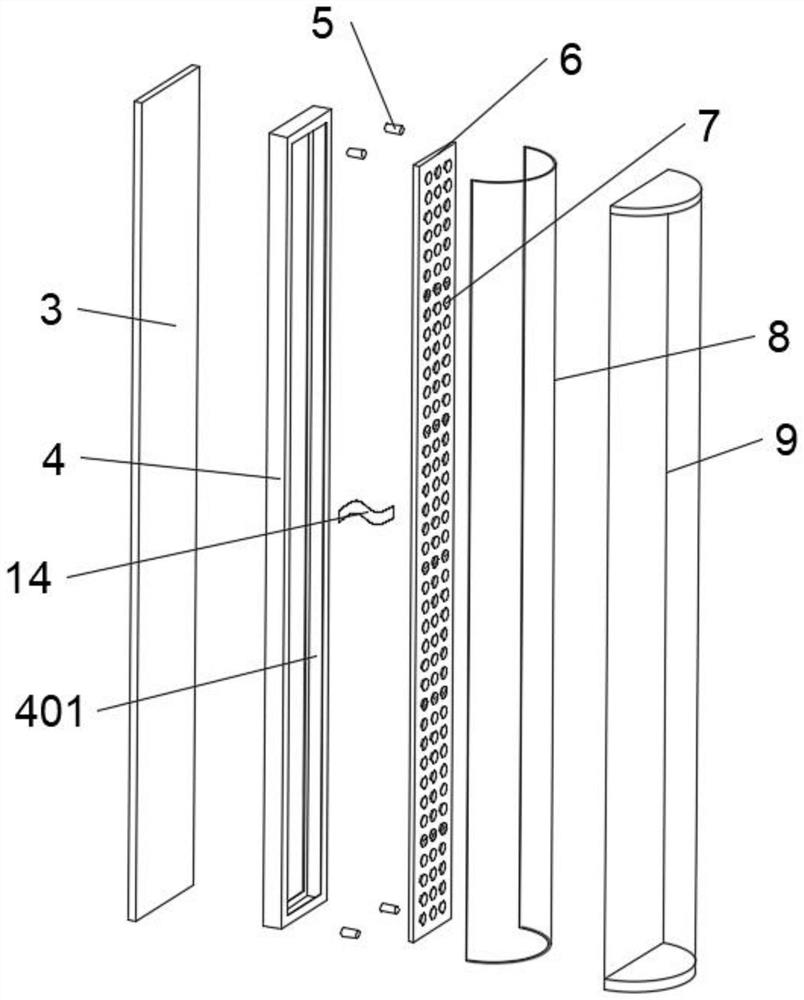

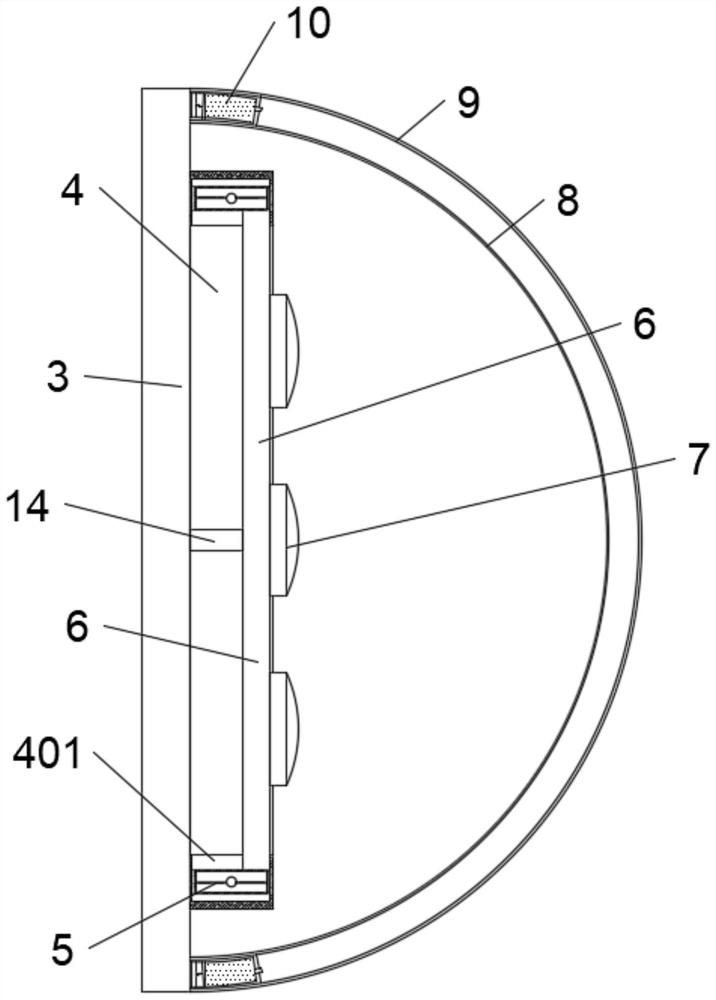

[0048] see Figure 1-10 , a plant lighting system based on laser pulses, including a light incubator body 1 and a side light fan blade 2 symmetrically rotatably connected to the light incubator body 1, and a plurality of electrified base plates are fixedly installed on the side light fan blade 2 3. A fine-tuning frame 4 is fixedly installed on the front end of the energized bottom plate 3, and the inner wall of the fine-tuning frame 4 is symmetrically provided with 401, and the light direction adjustment assembly 5 is fixedly installed inside the 401, and the two light direction adjustment assemblies 5 are respectively installed in the two 401's The front and rear walls are different, and the sides of the two light direction adjustment components 5 close to each other are fixedly connected with a branch branch plate 6. The front end of the branch branch plate 6 is fixedly installed with a plurality of pulsed strong light lamps 7, and the front end of the electrified base plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com