Novel vacuum induction melting furnace

A technology of vacuum induction melting and vacuum heating furnace, which is applied in the direction of furnaces, crucible furnaces, furnace components, etc. It can solve the problems of unreasonable design of induction heating coil structure, equipment can not work for a long time, and the heating time of the device is long, so as to improve the melting efficiency. The effect of maintaining vacuum and reducing the energy consumption of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

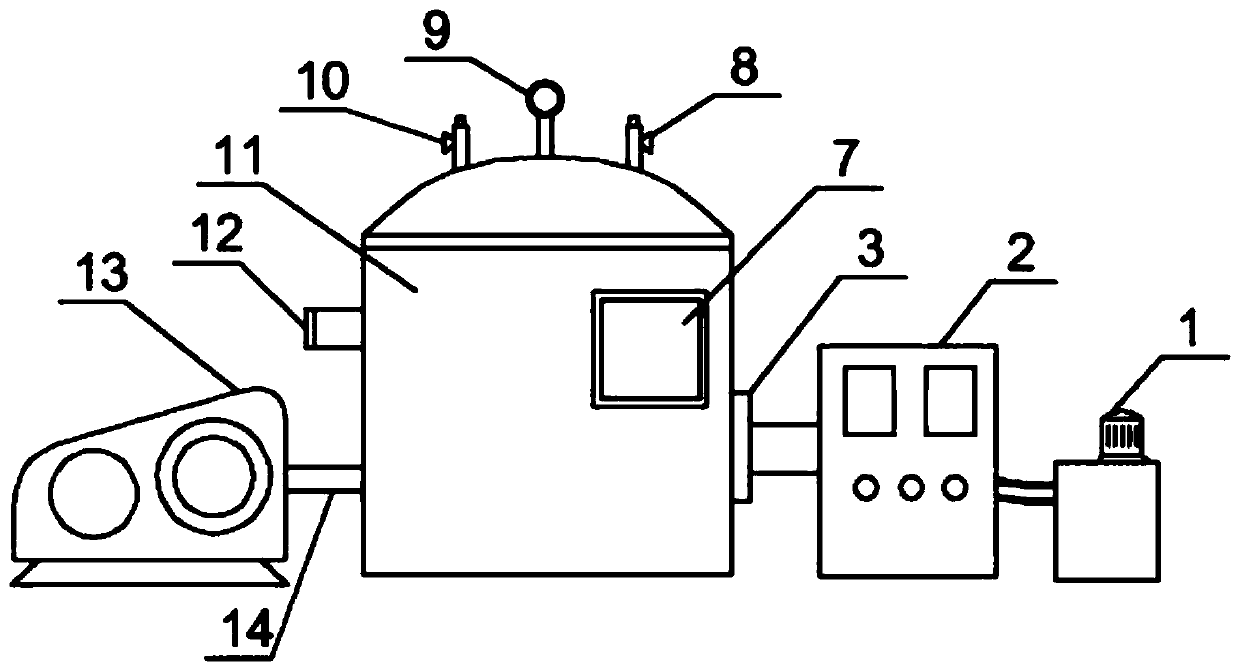

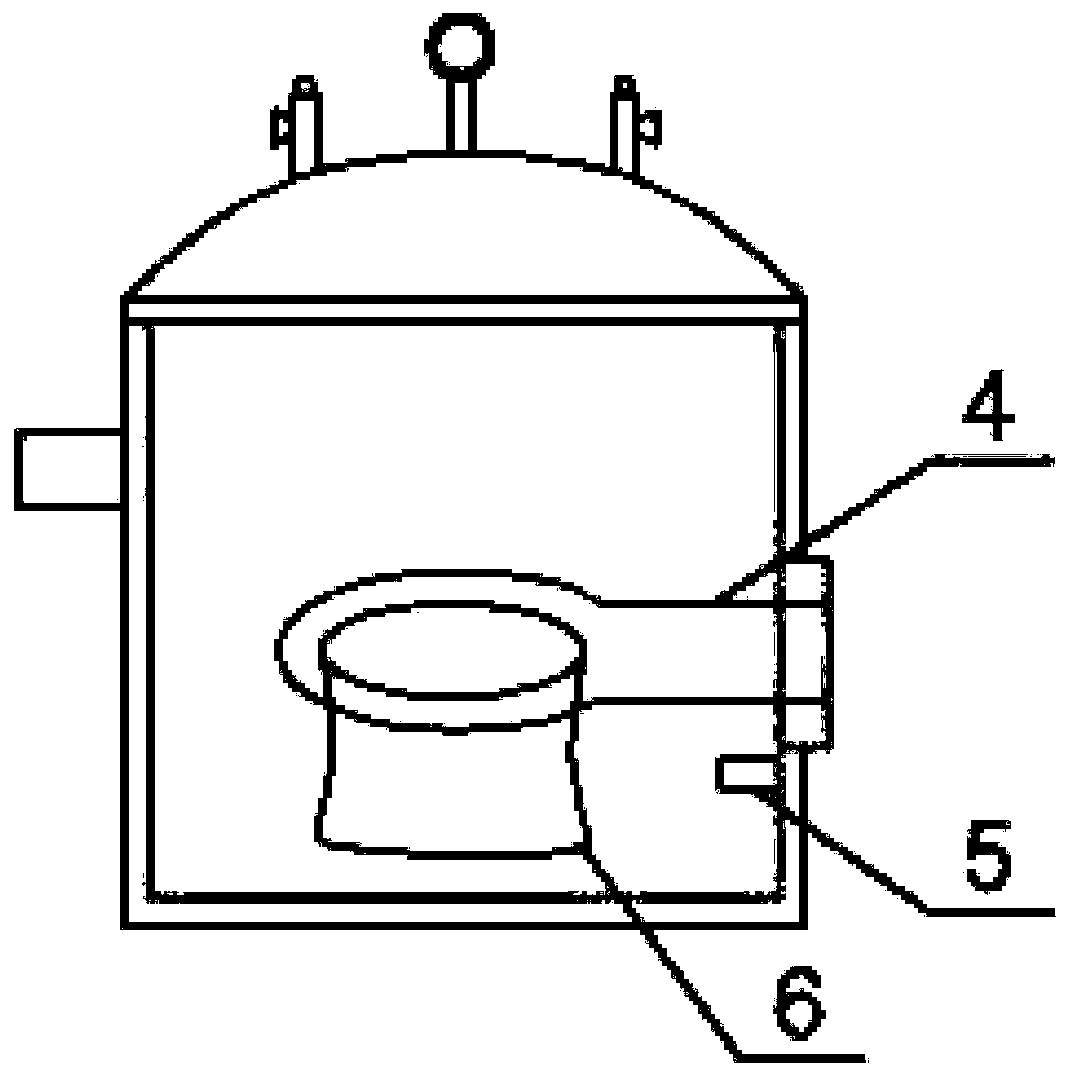

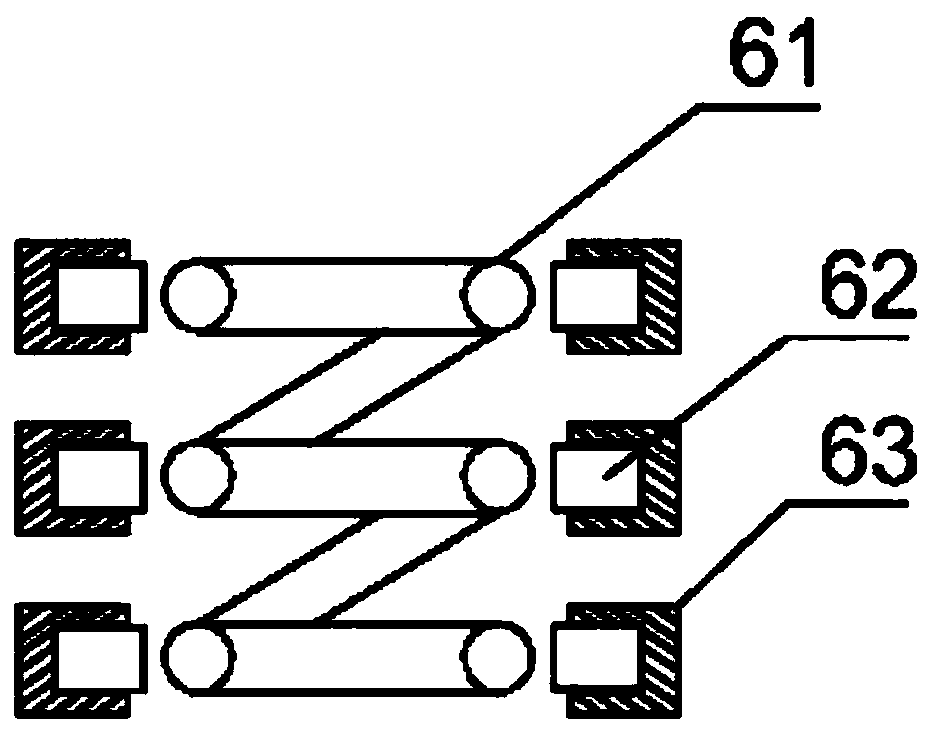

[0024] as attached figure 1 to attach image 3 shown

[0025] The present invention provides a novel vacuum induction melting furnace, comprising a cooling system 1, a high-frequency induction machine 2, an insulating partition 3, a high-frequency induction heating coil 4, a temperature detector 5, a crucible 6, a temperature display screen 7, and an air inlet valve 8. Vacuum gauge 9, intake valve 10, vacuum heating furnace 11, observation window 12, vacuum pump 13 and vacuum bellows 14, the cooling system 1 is connected with the high-frequency induction machine 2 through a cooling water pipe; The plate 3 is installed on the side of the vacuum heating furnace 11; the high-frequency induction heating coil 4 passes through the insulating partition 3 and enters the vacuum heating furnace 11; the temperature detector 5 is arranged in the vacuum heating furnace 11; The crucible 6 is placed in the high-frequency induction heating coil 4; the temperature display screen 7 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com