Anolyte clarifying tank waste chlorine gas recovery technology in ionic membrane caustic soda production

A technology of ionic membrane caustic soda and anolyte, applied in the direction of chlorine/hydrogen chloride, chlorine/hydrogen chloride purification, etc., can solve the problems of waste, unrealized utilization of waste acid water, consumption of caustic soda, etc., achieve small investment, normal operation of the production system, avoid The effect of damaging the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

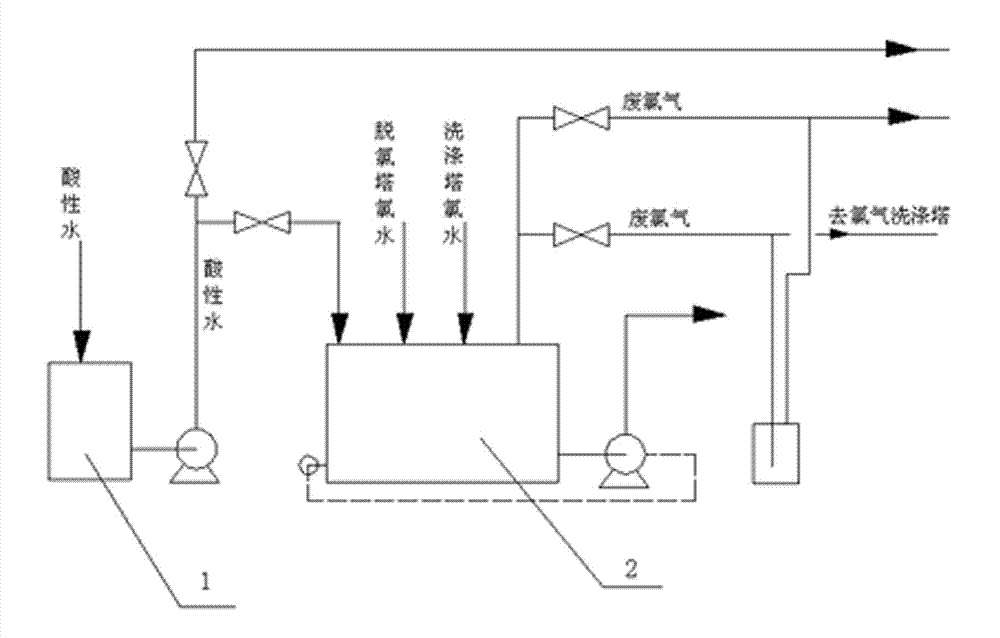

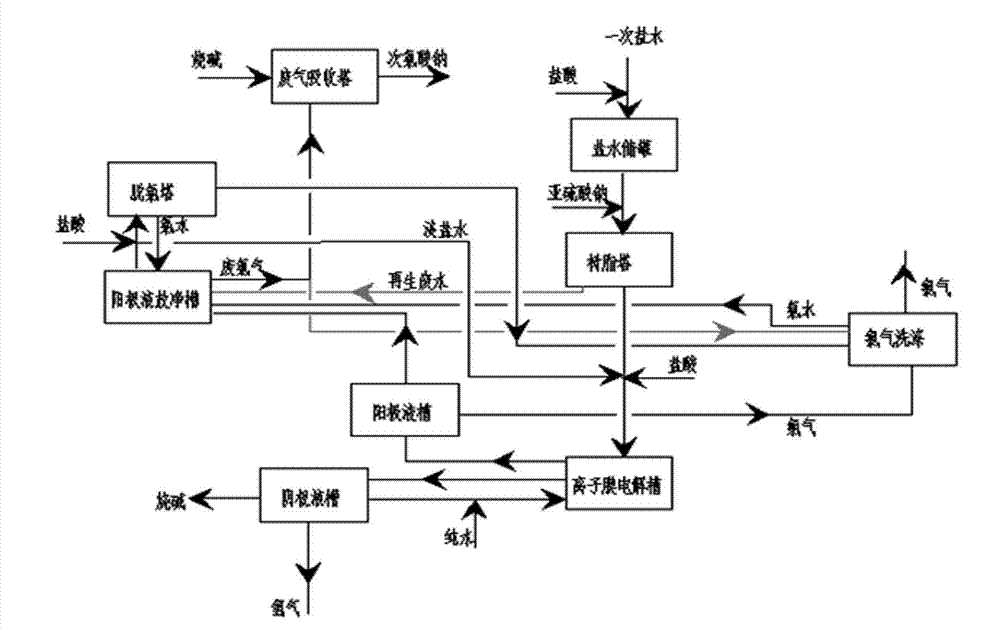

Embodiment 1

[0028] The waste acid water from the regeneration of the resin tower in the secondary brine process first enters the waste water tank, and is slowly sent to the anolyte discharge tank by the waste water pump. The waste acid water enters the waste water tank for 3.5 hours, a total of 30m 3 , control the flow rate of waste acid water to 3.5m 3 / h into the anolyte drain tank. The saturated chlorine water from the chlorine gas scrubber and dechlorination cooler enters the anolyte discharge tank, and reacts with the resin regeneration waste acid water from the waste water tank to decompose a larger amount of chlorine gas. The remote liquid level gauge and frequency conversion controller are all connected to the DCS control system, and the pressure of the chlorine main pipe is -1.3 kPa. The purity of chlorine gas meets the requirements of the production system indicators and can be produced stably.

Embodiment 2

[0030] The waste acid water from the regeneration of the resin tower in the secondary brine process first enters the waste water tank, and is slowly sent to the anolyte discharge tank by the waste water pump. The waste acid water enters the waste water tank for 3.5 hours, a total of 30m 3 , control the flow rate of waste acid water to 4m 3 / h into the anolyte drain tank. The saturated chlorine water from the chlorine gas scrubber and dechlorination cooler enters the anolyte discharge tank, and reacts with the resin regeneration waste acid water from the waste water tank to decompose a larger amount of chlorine gas. The remote liquid level gauge and frequency conversion controller are all connected to the DCS control system, and the pressure of the chlorine main pipe is -1.5 kPa. The purity of chlorine gas meets the requirements of the production system indicators and can be produced stably.

Embodiment 3

[0032] The waste acid water from the regeneration of the resin tower in the secondary brine process first enters the waste water tank, and is slowly sent to the anolyte discharge tank by the waste water pump. The waste acid water enters the waste water tank for 3.5 hours, a total of 30m 3 , control the flow rate of waste acid water to 4.5m 3 / h into the anolyte drain tank. The saturated chlorine water from the chlorine gas scrubber and dechlorination cooler enters the anolyte discharge tank, and reacts with the resin regeneration waste acid water from the waste water tank to decompose a larger amount of chlorine gas. The remote liquid level gauge and frequency conversion controller are all connected to the DCS control system, and the pressure of the chlorine main pipe is -1.2 kPa. The purity of chlorine gas meets the requirements of the production system indicators and can be produced stably.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com