Hydraulic lifter garbage truck cover plate turnover control system

A technology of overturning control and garbage trucks, which is applied in the direction of garbage storage, transportation and packaging, etc. It can solve the problems of increasing the labor intensity of sanitation workers, mutual interference, and increasing damage to driving roads, and is easy to promote and use in large quantities and on a large scale. Avoid mutual interference and avoid damage to equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

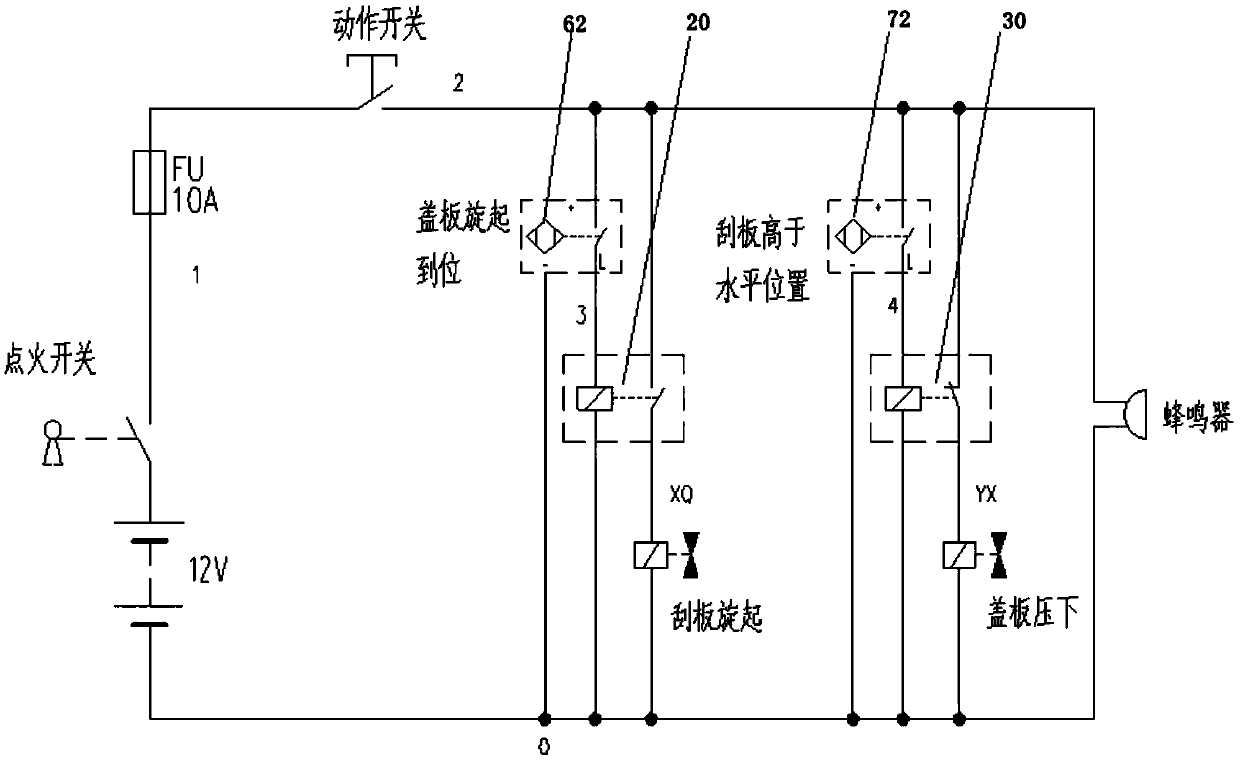

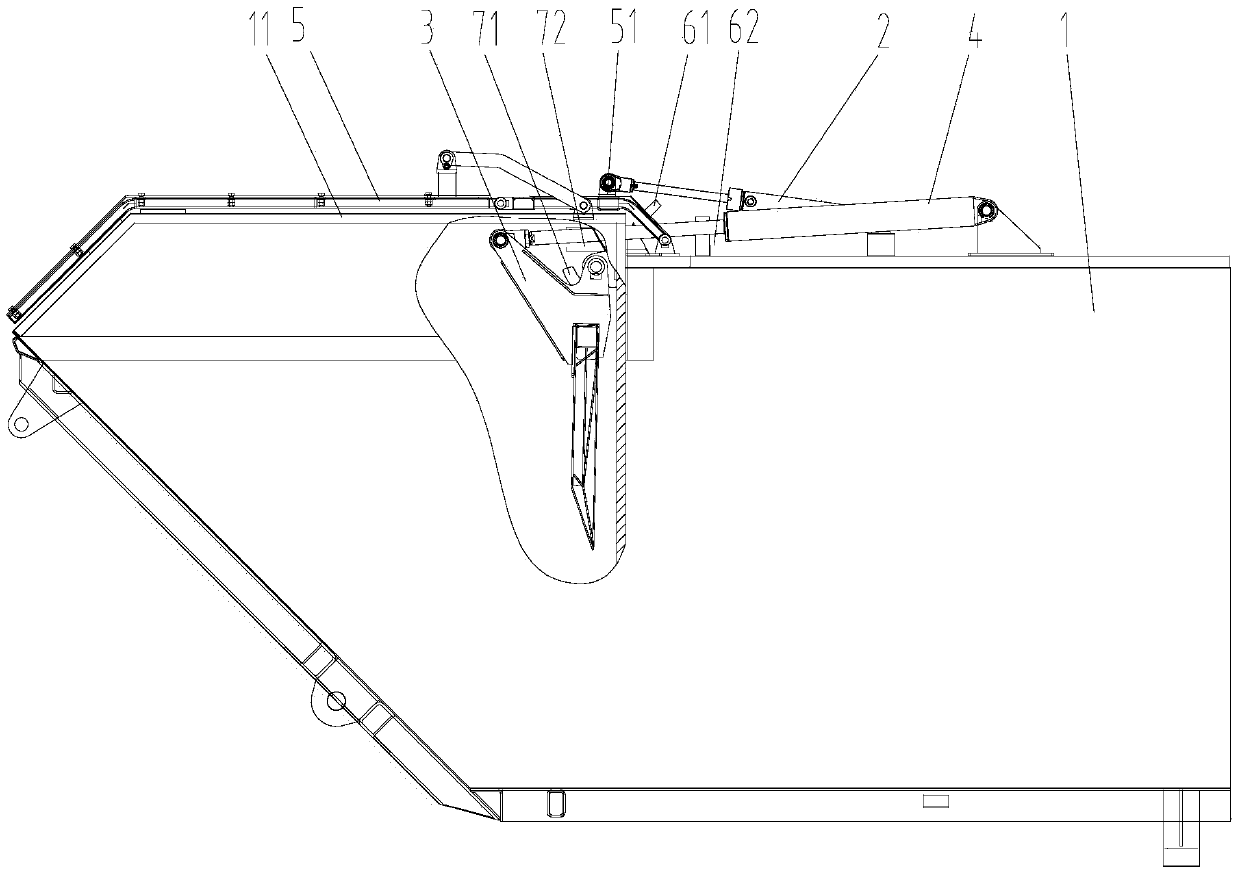

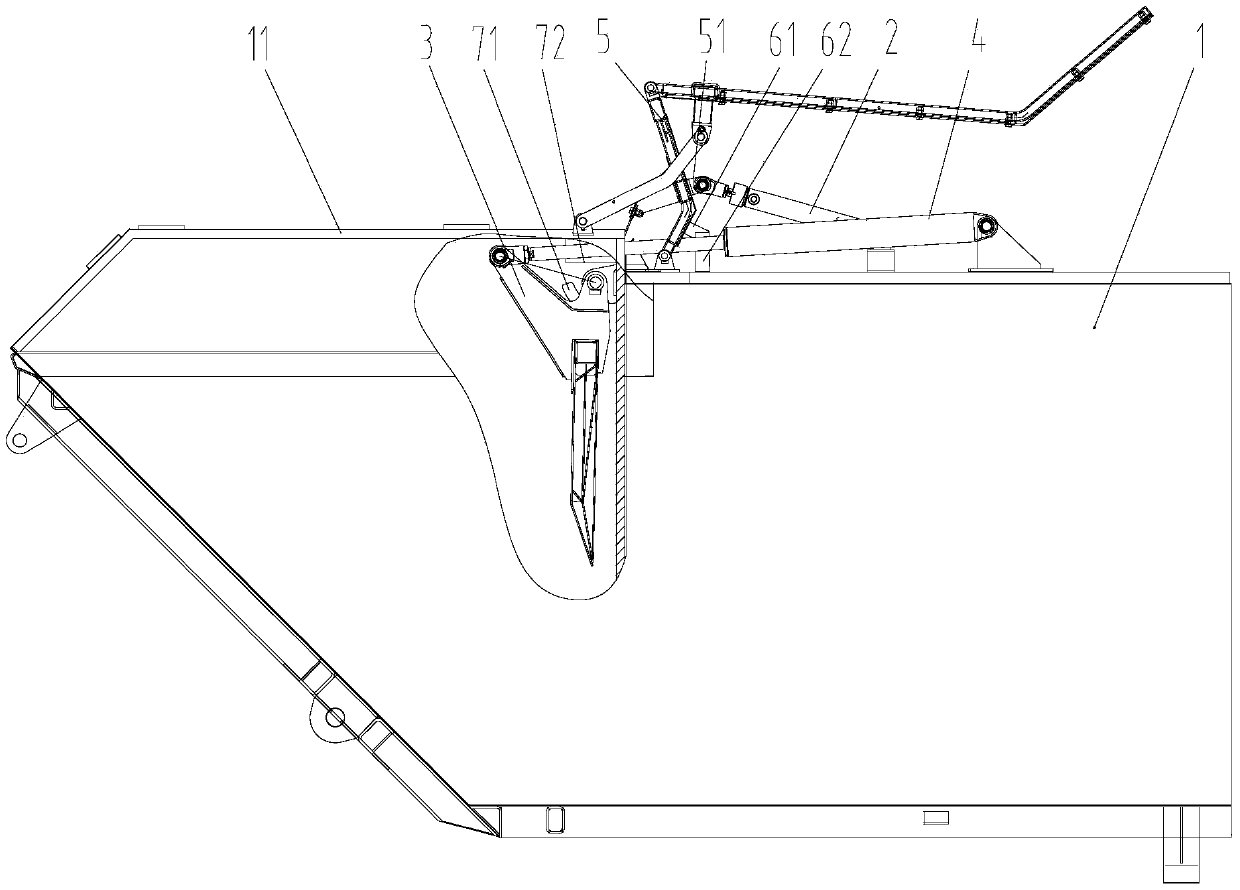

[0025] Such as Figures 1 to 6 As shown in one of them, the present invention includes a cover plate 5, a cover plate oil cylinder 2, a cover plate solenoid valve 30, a first sensing assembly, a scraper 3, a scraper oil cylinder 4, a scraper electromagnetic valve 20, and a second sensing assembly,

[0026] The box body 1 of the garbage truck is provided with a garbage bucket 11 with an upward opening, the cover plate 5 covers the garbage bucket 11 of the box body 1 of the garbage truck, and one end of the cover plate 5 is hinged on the top of the box body 1 One end of the cover oil cylinder 2 is hingedly fixed on the upper surface of the cover plate 5, and the other end of the cover plate oil cylinder 2 is hingedly fixed on the top position of the box body 1, and the cover plate oil cylinder 2 drives the cover plate 5 around the gap between the cover plate and the box body 1. hinge point rotation,

[0027] The scraper 3 is hingedly arranged on the opening edge of the upper en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com