Duplicating machine and laser printer color toner manufacturing technique

A technology of laser printers and copiers, applied in optics, electrography, instruments, etc., can solve the problems of limiting fixing speed, sucking up, and waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

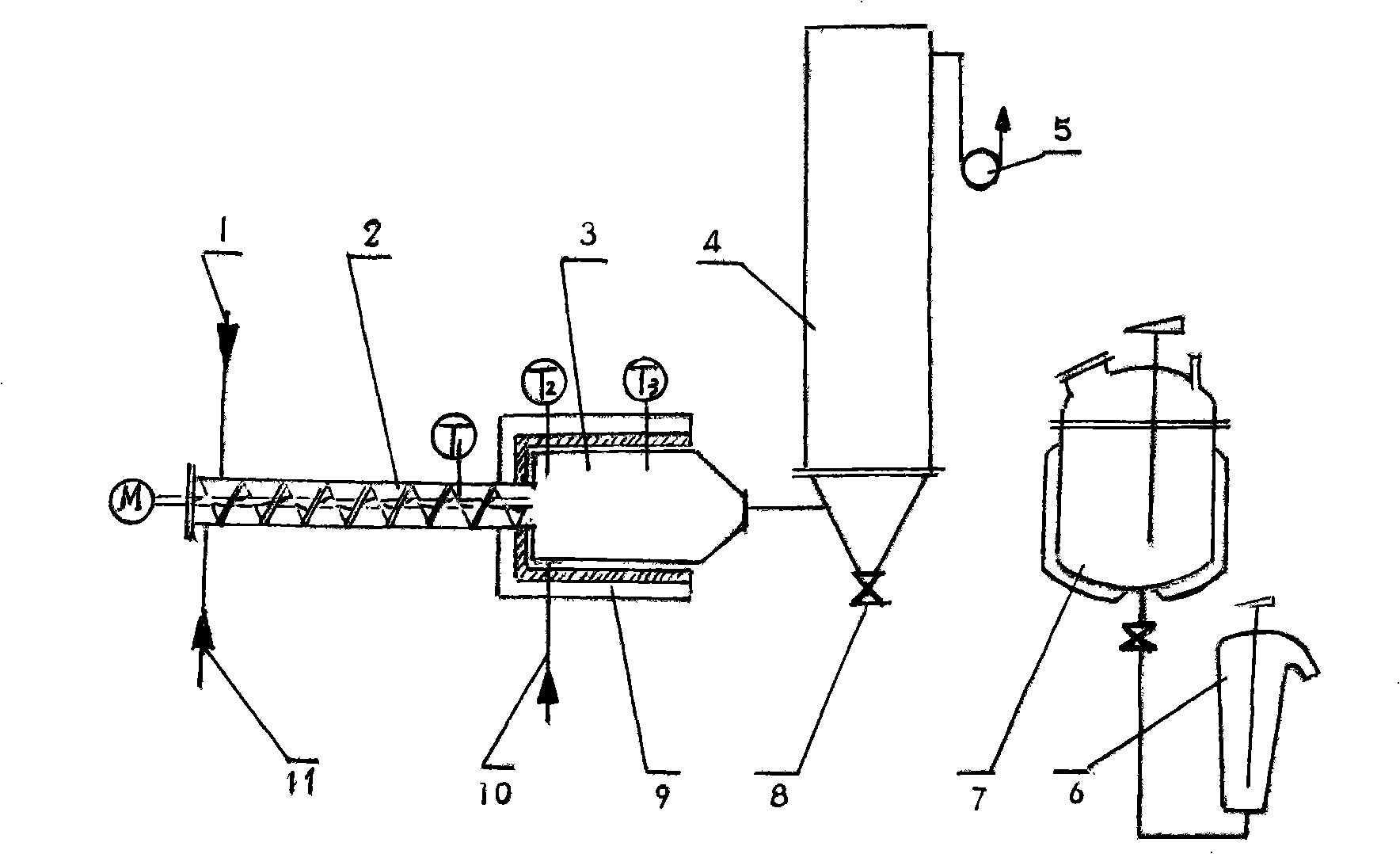

[0010] Embodiment 1 blue toner production technology, nano-SiO 2 The agglomerates were broken up by ultrasonic vibration, and the figure 1 The feeding port 1 is added to the screw feeder 2, and Fe(CO) is fed through the feeding port 11 5 , to control the SiO 2 with Fe(CO) 5 The feed ratio and T 1 The temperature is 160±50℃, so that Fe(CO) 5 decomposed into Fe wrapped in SiO 2 In addition, without forming Fe particles, the outlet of the screw feeder 2 is connected to the reactor 3 preheated to 100-500°C, the temperature T3≥T2, and at the same time, water vapor is introduced through the pipe 10, and the reaction is

[0011] Fe(CO) 5 (g)=Fe(S)+5CO(g) ①

[0012] 3Fe(s)+4H 2 O(g)=Fe 3 o 4 (s)+4H 2 (g) ②

[0013] Generate package Fe 3 o 4 SiO 2 The powder is reacted to generate H 2 and CO into collector 4, H 2 and CO are taken out by the vacuum pump 5 and recycled, and the powder collected by the collector 4 is magnetically separated, and there is no soft magnetic S...

Embodiment 3

[0018] Embodiment 3 yellow toner production technology, figure 1 In the process, the ultrasonically dispersed nano-TiN is added to the screw feeder 2 with the temperature set at 100-200°C through the feeding port 1, and Fe(CO) is fed through the tube 11 at the same time. 5 (g), the other end of the screw feeder 2 is connected to the reactor 3 whose temperature is set at 100~~500° C. The Fe generated by the decomposition of the carbonyl compound is wrapped outside the TiN, and then reacts with the air entering through the pipe 10 to make the Fe Generating r-Fe 2 o 3 , the solids are reacted to generate CO and H 2 into collector 4, CO and H 2 Taken away by vacuum pump 5. The powder taken out from the valve 8 under the collector 4 is magnetically separated, the non-magnetic powder is reworked, and the magnetic powder is added with AS (or L 4G) In the epsilon-caprolactone of naphthol and the styrene containing GC (or RC) chromophore and initiator, add the water containing acc...

Embodiment 4

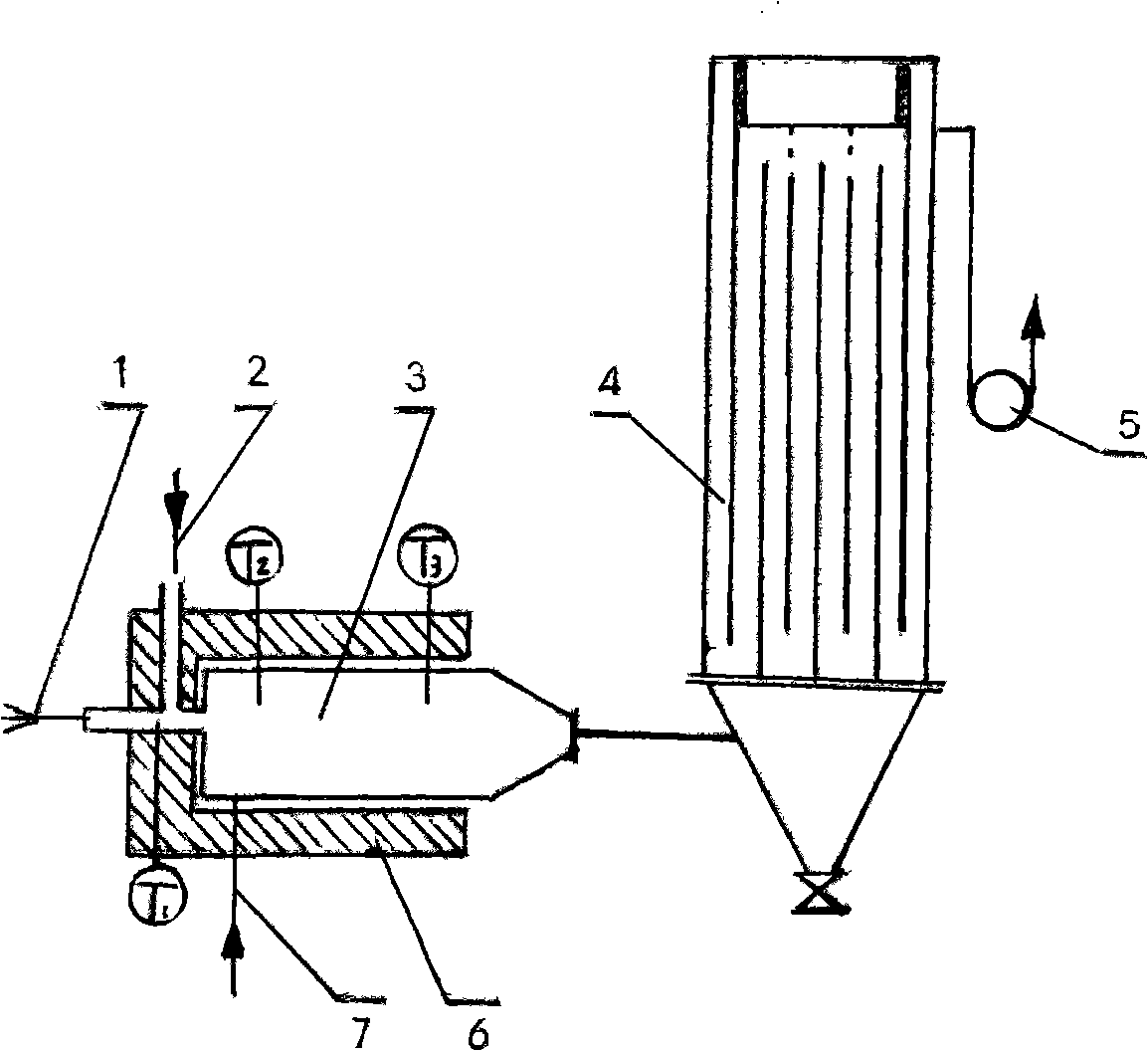

[0019] Embodiment 4 black toner production technology: in figure 2 In the process, mineral oil or unsaturated hydrocarbons are added from the feed port 2, and are brought into the reaction kettle 3 at 100-500 ° C with the air added from the pipe 1 and the carbon black is incompletely burned, and passed through the pipe 7 feed Fe(CO) 5 (g) and H 2 O(g), Fe(CO) 5 (g) Decompose first to form Fe, wrap it in carbon, and then react with water to form Fe 3 o 4 , the other end of the reactor 3 receives the collector 4 and collects the Fe 3 o 4 After magnetic separation, the carbon black is mixed with styrene, ε-caprolactone (or its oligomers), and initiator, and then added to the water containing the accelerator. Feed ratio is Fe 3 o 4 Carbon black: ε-caprolactone: styrene: initiator: accelerator: water = 1: 0.2~2: 0.2~2: 0.002~0.2: 0.001~0.1: 2~4 (w / w). Suspension polymerization under ultrasonic vibration and stirring for 0.5 to 4 hours, centrifuge, and dry to obtain black ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com