Thermal treatment method for improving low-temperature impact toughness of austenite-ferrite stainless steel

A technology of low temperature impact toughness and heat treatment method, applied in heat treatment equipment, heat treatment process control, manufacturing tools, etc., can solve the problems of poor impact toughness, unable to meet the requirements of use, etc., and achieve the effect of reducing plasticity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

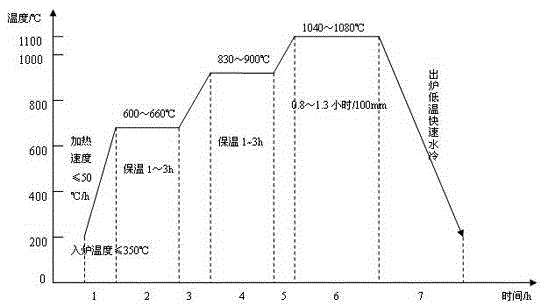

[0017] A heat treatment method for improving low-temperature impact toughness of austenitic-ferritic stainless steel, the method is as follows:

[0018] 1) After the austenitic-ferritic stainless steel is forged, install the furnace under the condition that the furnace temperature is not higher than 350°C, and preheat twice;

[0019] 2) The temperature of the first preheating is 600°C, the heating rate is 0<50°C / h, and the temperature is kept for 1h; the temperature of the second preheating is 830°C, the temperature is kept for 1h, and then solid solution treatment is carried out;

[0020] 3) The solid solution temperature is 1040°C, the holding time is 0.8 hours / 100mm, and then cooled;

[0021] 4) Put it into clean water with an initial temperature of less than 10°C, and keep it for 20 minutes at a cooling rate of 4 seconds / mm.

[0022] In the step 4), in order to control the temperature of the clear water, the clear water is continuously injected at a speed of 38 tons / hour....

Embodiment 2

[0024] A heat treatment method for improving low-temperature impact toughness of austenitic-ferritic stainless steel, the method is as follows:

[0025] 1) After the austenitic-ferritic stainless steel is forged, install the furnace under the condition that the furnace temperature is not higher than 350°C, and preheat twice;

[0026] 2) The temperature of the first preheating is 660°C, the heating rate is 0<50°C / h, and the temperature is kept for 3 hours; the temperature of the second preheating is 900°C, the temperature is kept for 3 hours, and then solid solution treatment is carried out;

[0027] 3) The solid solution temperature is 1080°C, the holding time is 1.3 hours / 100mm, and then cooled;

[0028] 4) Put it into clean water with an initial temperature of less than 10°C, and keep it for 20 minutes at a cooling rate of 6 seconds / mm.

[0029] In the step 4), in order to control the temperature of the clear water, the clear water is continuously injected at a speed of 40 ...

Embodiment 3

[0031] A heat treatment method for improving low-temperature impact toughness of austenitic-ferritic stainless steel, the method is as follows:

[0032] 1) After the austenitic-ferritic stainless steel is forged, install the furnace under the condition that the furnace temperature is not higher than 350°C, and preheat twice;

[0033] 2) The temperature for the first preheating is 630°C, the heating rate is 0<50°C / h, and the temperature is kept for 2 hours; the temperature for the second preheating is 870°C, the temperature is kept for 1 hour, and then solid solution treatment is performed;

[0034] 3) The solid solution temperature is 1060°C, the holding time is 1 hour / 100mm, and then cooled;

[0035] 4) Put it into clean water with an initial temperature of less than 10°C, and keep it for 20 minutes at a cooling rate of 5 s / mm.

[0036] In the step 4), in order to control the temperature of the clear water, the clear water is continuously injected at a speed of 39 tons / hour....

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com