Material adding and reducing coordinated manufacturing method

A technology of collaborative manufacturing, adding and subtracting materials, applied in the direction of manufacturing tools, other manufacturing equipment/tools, plasma welding equipment, etc., can solve the problems of low efficiency of material addition, large thermal deformation of the substrate, and low forming accuracy, so as to improve the forming quality , Improve the flatness, improve the effect of precision and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

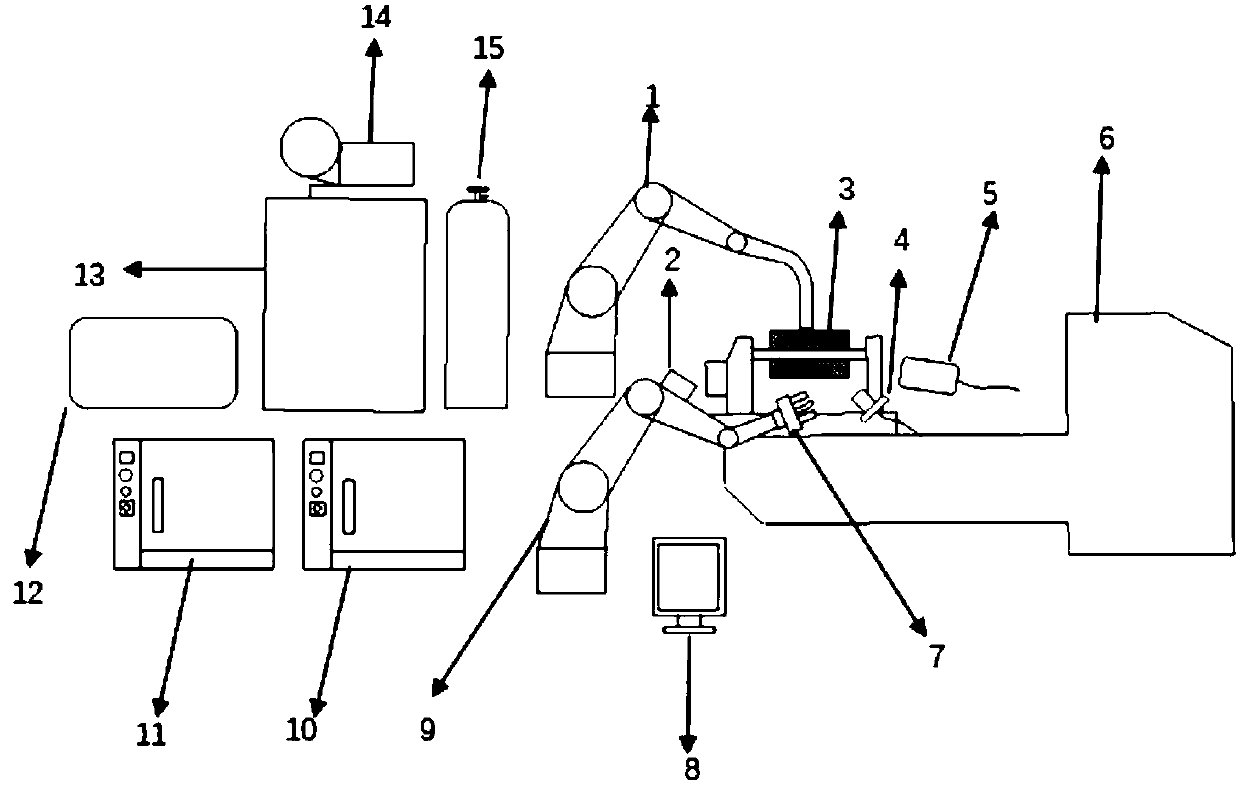

[0037] Using the collaborative manufacturing equipment system of adding and subtracting materials, the details of this embodiment are as follows:

[0038] Among them, the welding wire used for the additive is ER130S-G high-strength steel welding wire with a diameter of 1.2mm; the substrate is a 6mm thick 304 stainless steel substrate, and the welding torch is a CMT welding torch

[0039] Step 1: According to the size and shape of the workpiece to be formed, use CAD to build the model, and automatically generate the trajectory of the additive material by the computer;

[0040] Step 2: Set the welding parameters, where the wire feeding speed is 7.2mm / min; the welding speed is 11mm / s, the welding torch on the same side is lifted up 2mm when the next layer is added, and the shielding gas flow rate is 20L / min.

[0041] Step 3: Turn on the power supply, wait for the collaborative manufacturing equipment system of adding and subtracting materials to be ready, turn on the protective g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com