Method for sampling special organic gas in flue gas

A technology of organic gas and flue gas, applied in the direction of sampling devices, etc., can solve the problems of inconvenient operation, inconvenience, and heavy equipment to carry, and achieve the effects of preventing adsorption or contamination loss, easy cleaning, and convenient on-site connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

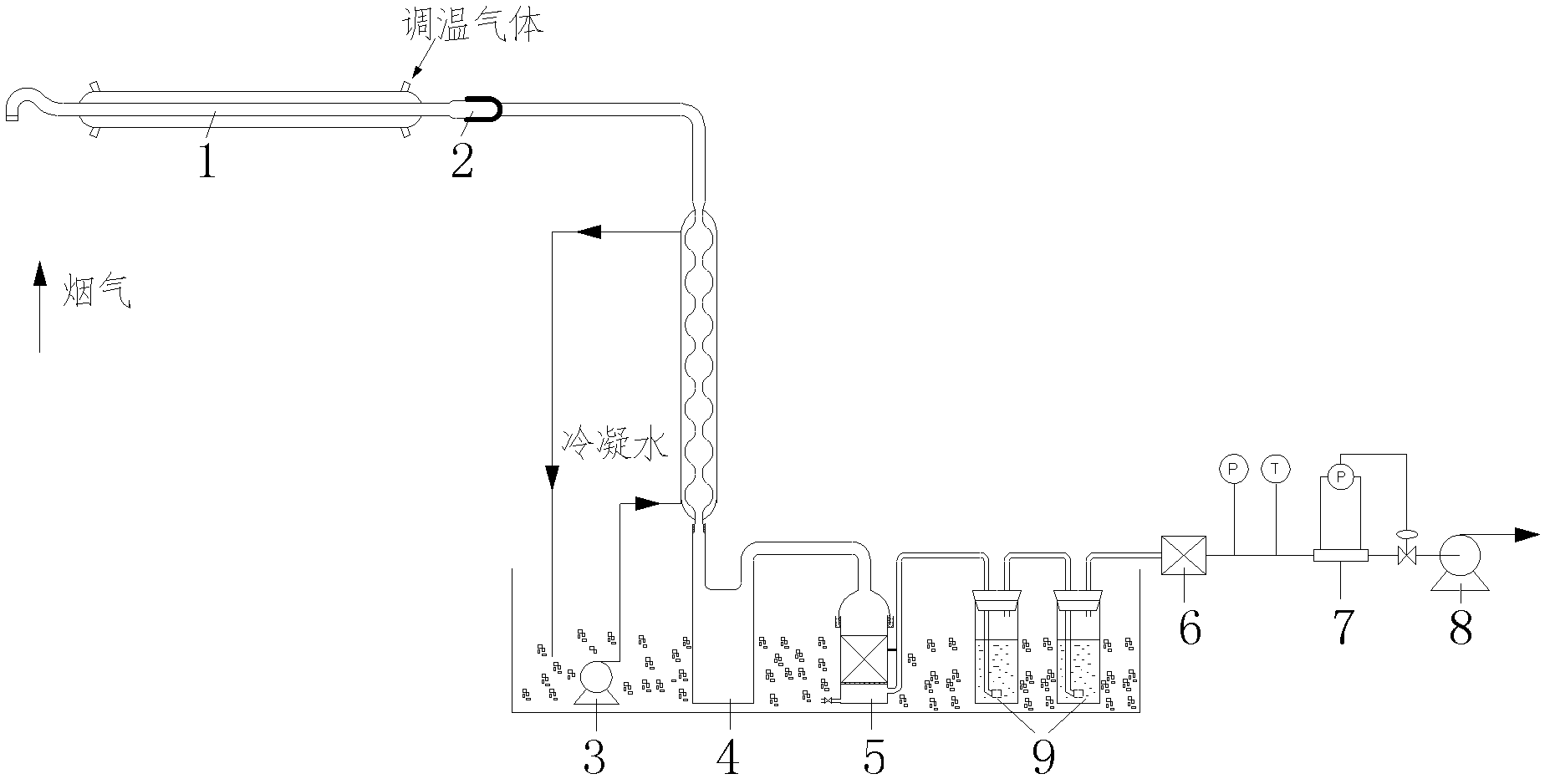

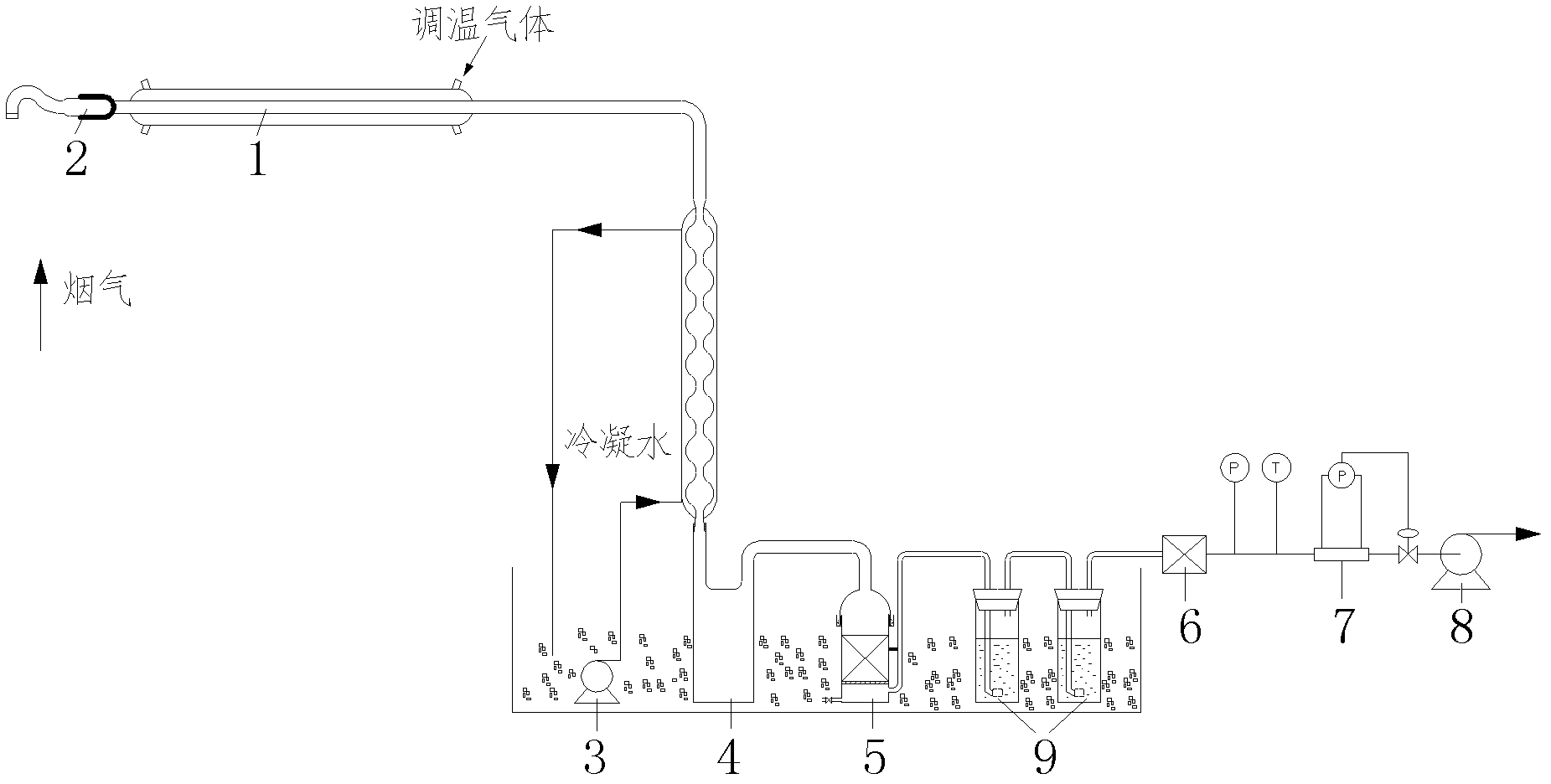

[0027] A method for sampling special organic gases in flue gas, using devices such as figure 1 As shown, the flue gas enters from the inlet of the sampling gun 1 through the inner tube of the sleeve. After passing through the jacketed quartz glass sampling gun, its temperature reaches the sampling requirements for dioxins. The flue gas passes through the filter cartridge 2 to trap particulates, and then Condensed by the condensing device, the condensate directly falls into the cooling liquid removal bottle 4, a chilled water pump 3 is arranged in front of the cooling liquid removal bottle 4, and the smoke is captured by the dioxin adsorption trap bottle 5 (containing adsorbent such as XAD resin) The dioxins in the gas are further collected by the bottle washing 9 and the gas passes through the dryer 6, the gas flow meter, the thermometer 7, and the sampling pump 8, to complete the entire sampling process.

[0028] Considering the influence of flue gas temperature and humidity on t...

Embodiment 2

[0030] A method for sampling special organic gases in flue gas, using devices such as figure 1 As shown, the flue gas enters from the inlet of the sampling gun 1 through the inner tube of the sleeve. After passing through the jacketed quartz glass sampling gun, its temperature reaches the sampling requirements for dioxins. The flue gas passes through the filter cartridge 2 to trap particulates, and then Condensed by the condensing device, the condensate directly falls into the cooling liquid removal bottle 4, a chilled water pump 3 is arranged in front of the cooling liquid removal bottle 4, and the smoke is captured by the dioxin adsorption trap bottle 5 (containing adsorbent such as XAD resin) The dioxins in the gas are further collected by the bottle washing 9 and the gas passes through the dryer 6, the gas flow meter, the thermometer 7, and the sampling pump 8, to complete the entire sampling process.

[0031] Considering the influence of flue gas temperature and humidity on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com