Bismuth ingot die

A mold and bismuth ingot technology, applied in the field of equipment for bismuth ingot manufacturing, can solve the problems of high equipment cost, complex structure of a refined bismuth thermal insulation casting device, cannot be cast at the same time, etc., achieves low cost, improves ingot casting speed and production efficiency, The effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

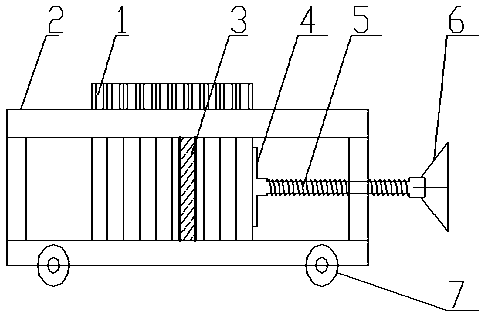

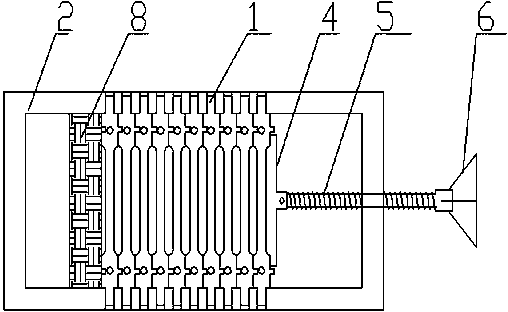

[0019] refer to figure 1 and figure 2 : A kind of bismuth ingot mould, is made up of 10 mold assemblies 1 and casting frame; Forms a casting cavity between described mold assembly 1; Described casting frame is made up of support 2, fixed beam 3, baffle plate 8, screw rod 5 , mold push plate 4 and screw rotating ring 6; the front and rear frame bars of the support 2 are provided with fixed beams 3; the frame bars at the top and bottom of the support 2 are provided with baffle plates 8; A screw 5 is provided; the left end of the screw 5 is connected with a mold push plate 4; the right side of the screw 5 is connected with the screw rotating ring 6; the mold assembly 1 is placed on the support 2; between the mold assemblies 1 Push the mold push plate 4 through the screw rod 5 and clamp it tightly.

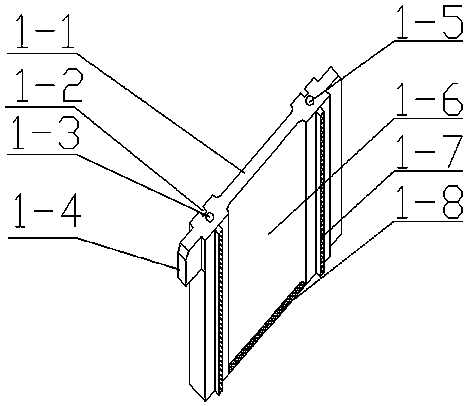

[0020] refer to Figure 3~6 , the mold assembly 1 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com