A mold cooler

A mold cooling and refrigerator technology, which is applied in the field of casting auxiliary tools, can solve the problems of increased defective rate, automatic control of mold cooling temperature, and the workpiece cannot meet the expected physical properties of the metal, so as to improve the yield, improve the heat dissipation effect, and accurately control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Further description will be given below in conjunction with the accompanying drawings

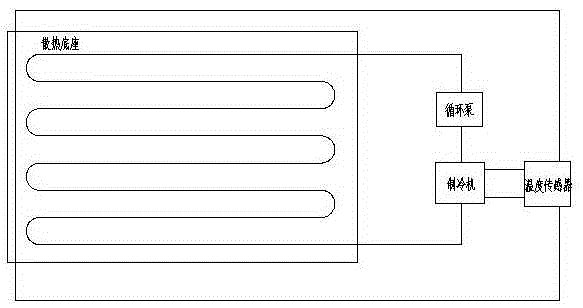

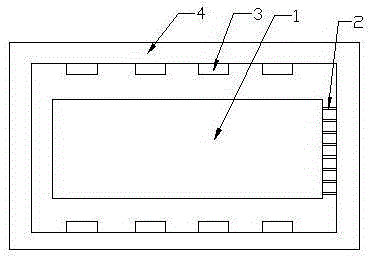

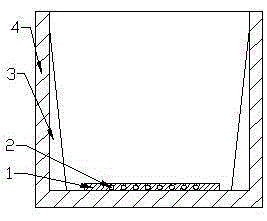

[0019] A mold cooler such as Figure 1~3 As shown, the mold cooler includes a refrigerator, a circulating pump, an outer casing 4, several clamping blocks 3 and a heat dissipation base 1, the outer casing 4 is a metal groove made of a heat-conducting metal, and the clamping block 3 The cross-section is a right triangle, and the two right-angled sides of the clamping block 3 are connected to the bottom and side of the outer shell 4. The clamping block 3 is made of flexible metal, and the bottom of the outer shell 4 is provided with The heat dissipation base 1, the heat dissipation base 1 is densely covered with interconnected metal heat pipes, the inside of the metal heat pipes is filled with a heat transfer fluid, and the heat transfer liquid forms a circulation loop through a metal conduit and a circulation pump, and the circulation loop is also connected with Refrigerator;

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com