A heat treatment method for re-sorbitizing steel wire or steel strip

A heat treatment method and sorbite technology, applied in the field of heat treatment, to achieve the effect of realizing sorbite structure size and realizing control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

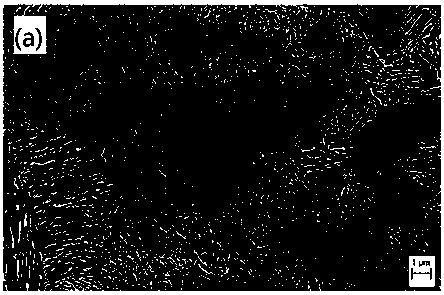

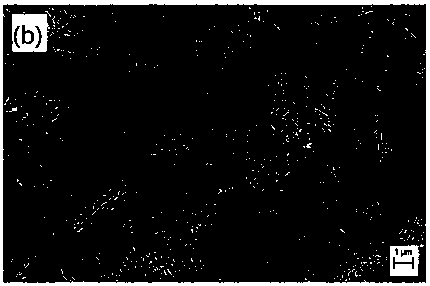

[0014] Example 1: 3.2 mm 70 steel cold-drawn steel wire is re-sorbitized and heat-treated, and the wire is heated to an austenite temperature of 860 ° C in a tube furnace. After a period of heat preservation, 0.5 The compressed air at -0.3 MPa immediately cools the steel wire out of the furnace. The steel wire is cooled while it is out of the furnace. Before being cooled by the compressed air, the temperature of the steel wire remains at the austenitizing temperature. -1s or so to complete, the time is controlled by the cooling speed of the compressed gas to ensure that any part of the steel wire will not be cooled below 200°C. The steel wire is forced to cool for 0.5-1s without any treatment, or it is allowed to enter a casing continuously and stand for a period of time. The resulting structure has a high sorbite rate, small interlamellar spacing, and a small sorbite group size, such as figure 1 and figure 2 as shown, figure 1 For the steel wire microstructure (SEM) after...

Embodiment 2

[0015] Example 2: For a 65Mn strip with a thickness of 0.75mm and a width of 15mm, heat it to 890°C for austenitization isothermal, and after cooling to 800°C, immediately use a cooling rate of 200-250°C / s for spraying. Cooling, the spray cooling time per unit length is about 2 seconds, and immediately leave the spray cooling port to cool naturally to room temperature.

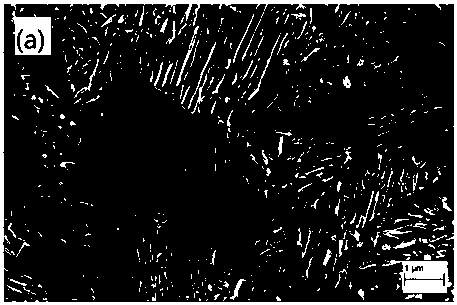

[0016] Such as image 3 and Figure 4 Shown: image 3 It is a sample SEM processed according to the method of the present invention, and its structure is mainly uniform and fine sorbite, and the sorbite rate is high. Figure 4 It is the SEM of the conventional salt bath isothermal quenching style, and the lamellar layer is obviously coarsened, and the massive proeutectoid ferrite is very obvious.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com