Coaxial powder feeding apparatus

A technology of coaxial powder feeding and powder feeding tube, which is applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of reducing the utilization rate of metal powder, affecting production efficiency, and uneven powder feeding, so as to ensure continuous performance and uniformity, improve the effective utilization rate, and avoid the effect of overall replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

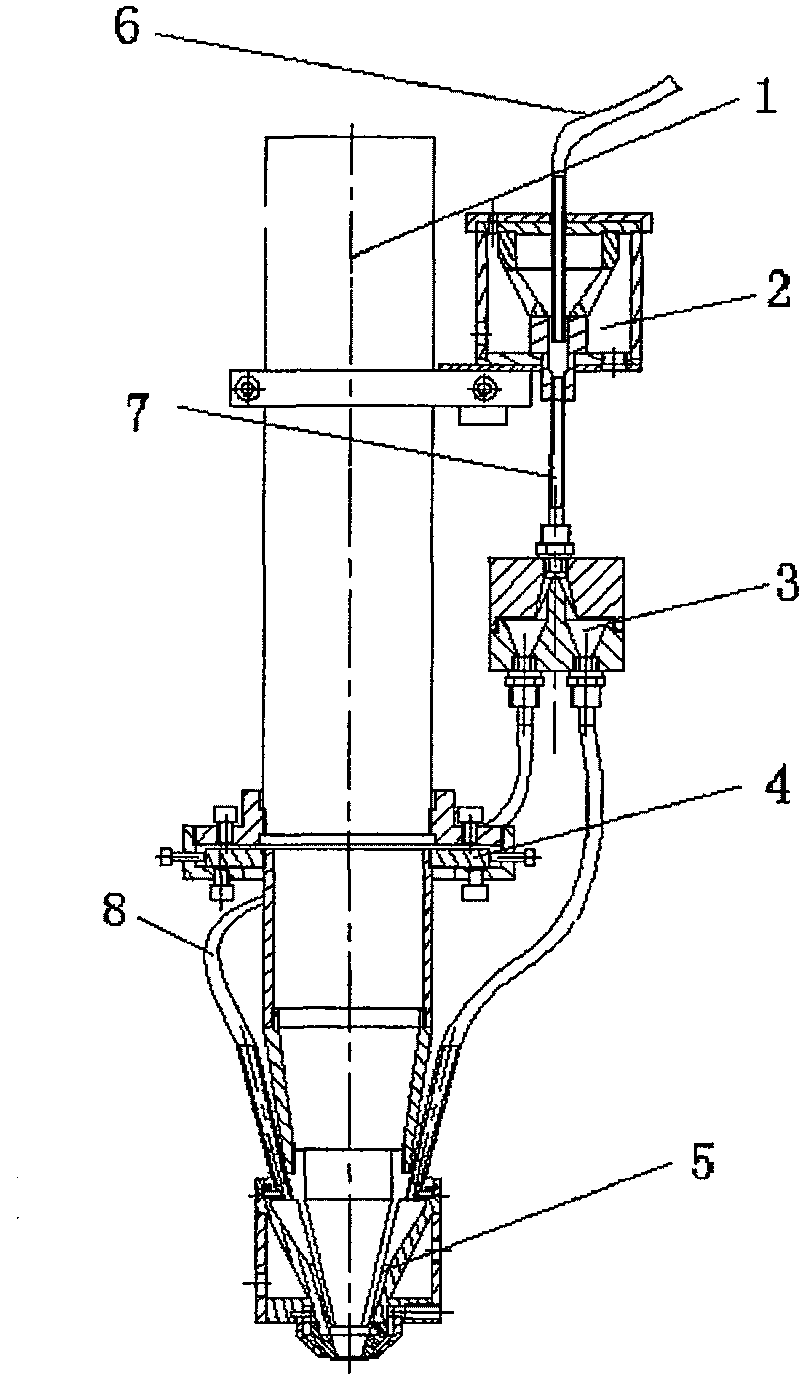

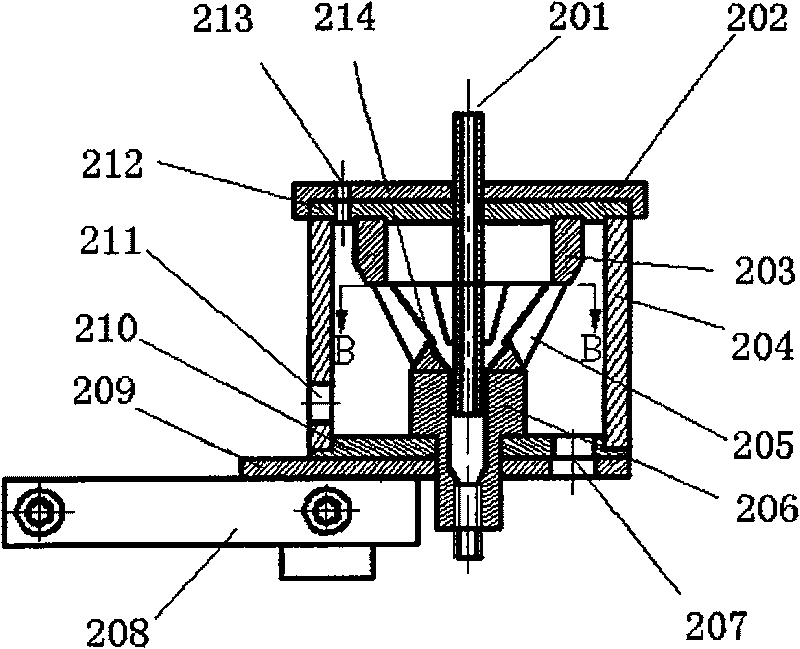

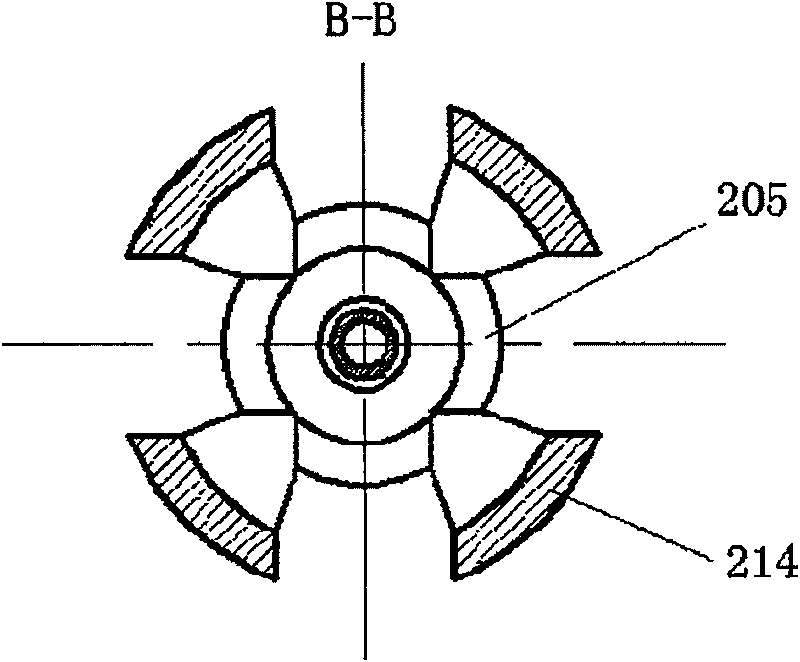

[0018] figure 1 It is an embodiment disclosed by the present invention. The coaxial powder feeding device is composed of five parts: a laser beam protection cylinder 1, a pressure reducing device 2, a powder separator 3, an adjusting device 4 and a coaxial powder feeding head 5, wherein: the pressure reducer 2 Fix the laser beam protection tube 1 with a bracket 208, the powder feeding pipe 6 communicates with the adjustable powder feeding pipe 201 of the pressure reducer 2, and the powder outlet at the lower end of the pressure reducer 2 connects with the upper end of the powder separator 3 through the powder feeding pipe 7 The powder inlet 301 is connected, and the lower end of the powder separator 3 divides four powder outlets into four powder inlets 503 of the coaxial powder feeding head 5 through the powder feeding tube 8; the laser beam protection cylinder 1 and the protection cylinder method on the adjustment device 4 The flange of the upper cylinder of the adjusting dev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com