A variable-pitch hollow screw micro-powder feeding device and its design method

A variable pitch, hollow technology, applied in the field of material transportation, can solve problems such as uneven feeding and poor powder feeding, achieve stable feeding, high accuracy and stability, and avoid uneven feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

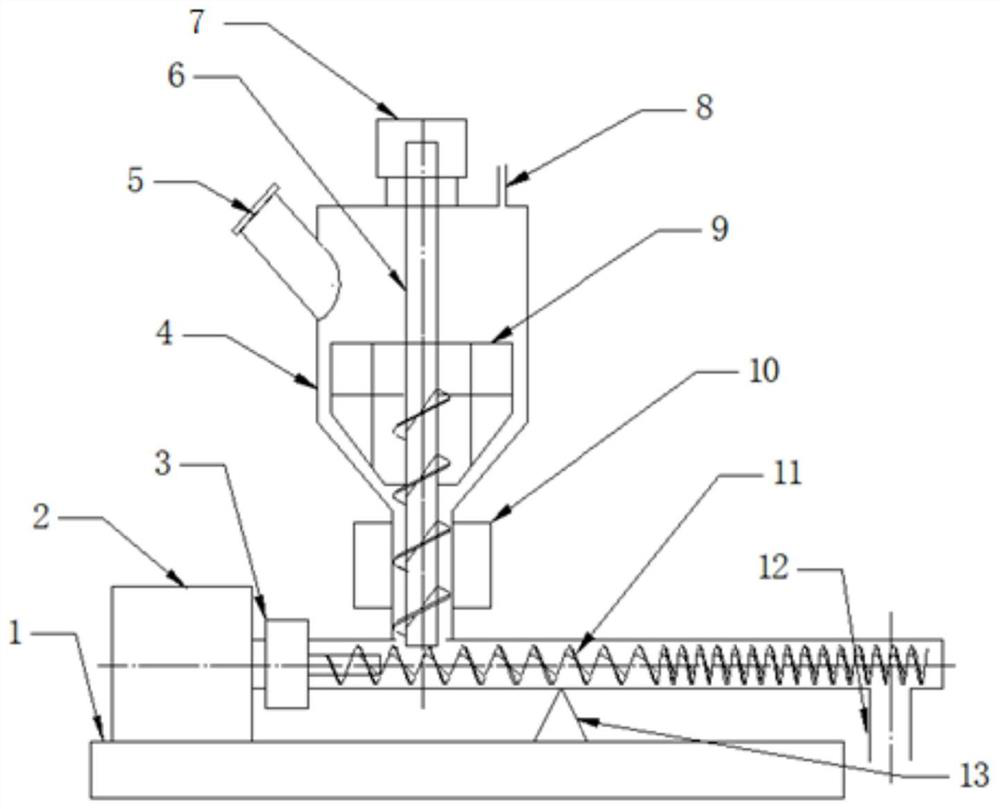

[0035] A variable-pitch hollow screw micro-powder feeding device according to an embodiment of the present invention includes: a base 1, a first servo motor 2, a coupling 3, a silo 4, a feed port 5, a stirring screw 6, a second servo motor 7, Air inlet 8, agitator 9, vibration motor 10, variable-pitch hollow feeding screw body 11 and discharge port 12.

[0036] Wherein, the first servo motor 2 is connected with the variable-pitch hollow feeding screw body 11 for conveying materials, and drives the variable-pitch hollow feeding screw body 11 to rotate to transport the material from the outlet of the silo to the discharge port 12 of the feeding device; the second servo motor The motor 7 is connected with the stirring screw 6 to drive the stirring screw 6 and the agitator 9 to rotate, preventing the materials in the silo from bridging, overhead and hardening; the air inlet and the feeding pipeline can be connected with a pipeline according to the actual experimental conditions to ...

Embodiment 2

[0039] see figure 1 , a variable-pitch hollow screw micro-powder feeding device according to an embodiment of the present invention is composed of a first stepping motor, a second stepping motor, a coupling 3, a variable-pitch hollow feeding screw 11, a vibrating motor 10, and a feeding port 5. It is composed of silo 4, stirring screw 6, air inlet 8, agitator 9, discharge port 12 and bracket 13. The variable-pitch hollow conveying screw body 11 is connected with the first stepping motor and the coupling 3, and is used to uniformly and continuously convey the materials falling from the outlet of the silo to the discharge port. The speed of the variable-pitch hollow conveying spiral body 11 can be adjusted according to The required feeding amount is adjusted; the stirring screw 6 is connected with the second stepping motor, the thread at the bottom of the stirring screw 6 can control the material in the silo to fall into the outlet of the silo evenly, and the agitator 9 fixed on...

Embodiment 3

[0045] A design method of a variable-pitch hollow spiral micro-powder feeding device according to an embodiment of the present invention includes the following steps:

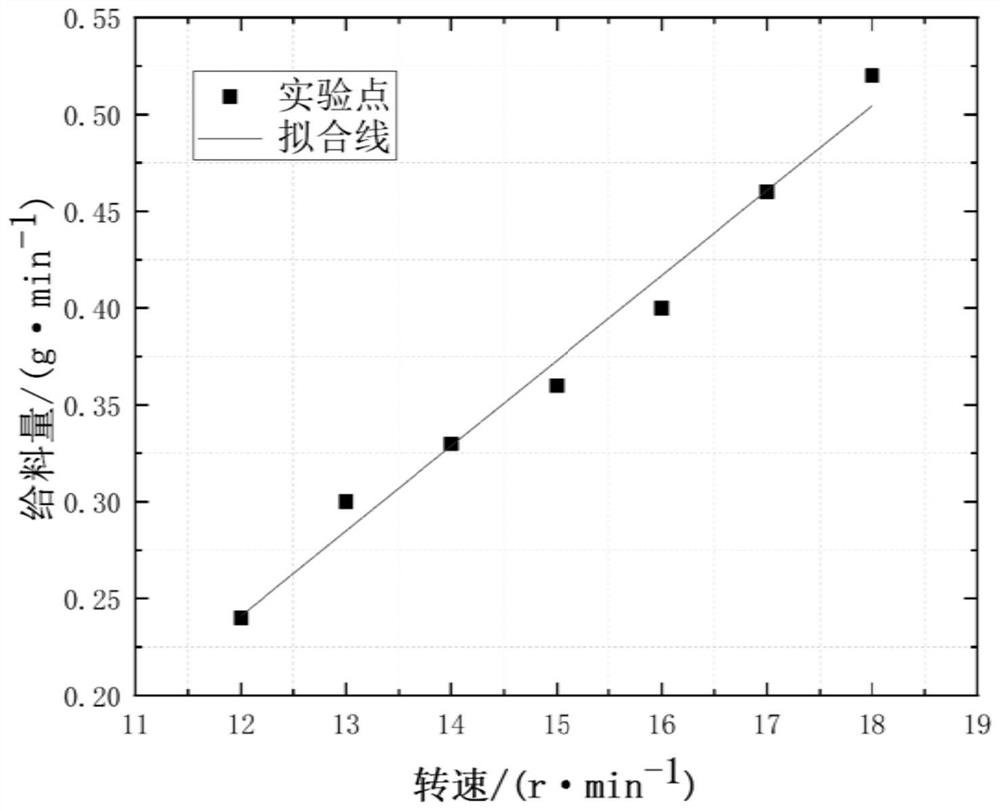

[0046] The screw feeding amount is directly related to the screw size and screw speed; among them, the screw size of the screw feeder is directly related to the feeding amount and structural size of the feeding device.

[0047] The variable-pitch hollow conveying screw pushes the conveyed material in a fixed casing and slips. Due to the gravity and the friction of the conveying pipe wall, the material does not move in translation with the screw rotation. The average speed of the material being pushed can generally be expressed according to the formula (1) calculation,

[0048] v=S n (1)

[0049] In the formula: v is the average speed of the material being pushed, m / min; S is the pitch of the variable-pitch hollow feeding screw, m; n is the speed of the variable-pitch hollow feeding screw, r / min.

[0050] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com