Laser cladding method for inner wall of hydraulic support oil cylinder

A hydraulic support and laser cladding technology, applied in maintenance and safety accessories, coatings, metal material coating processes, etc., can solve problems such as difficulty in reducing production costs, low material utilization, and inability to realize corners, and achieve a reduction in comprehensive Cost, overall cost reduction, high degree of freedom effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Below in conjunction with embodiment 1, the present invention is described in further detail.

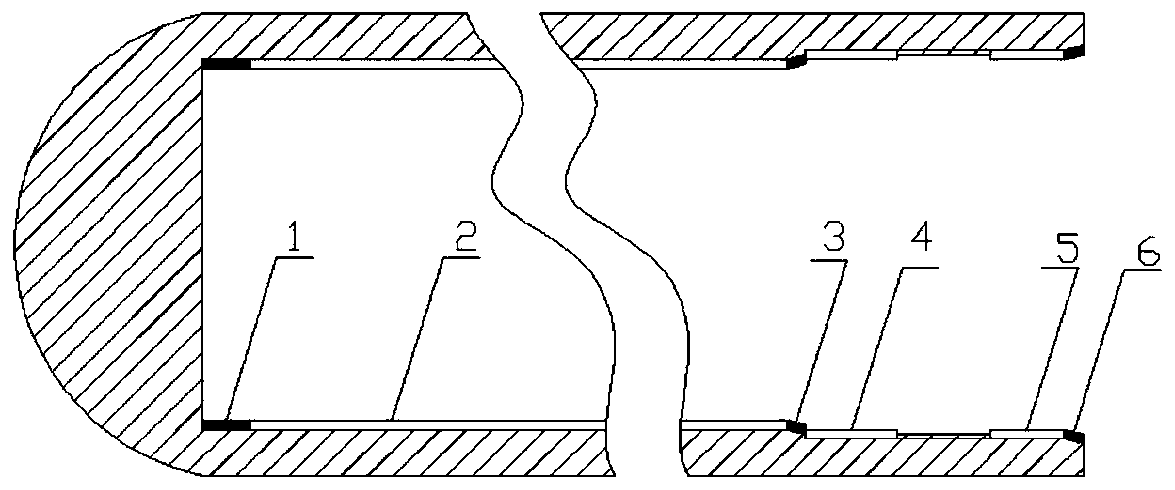

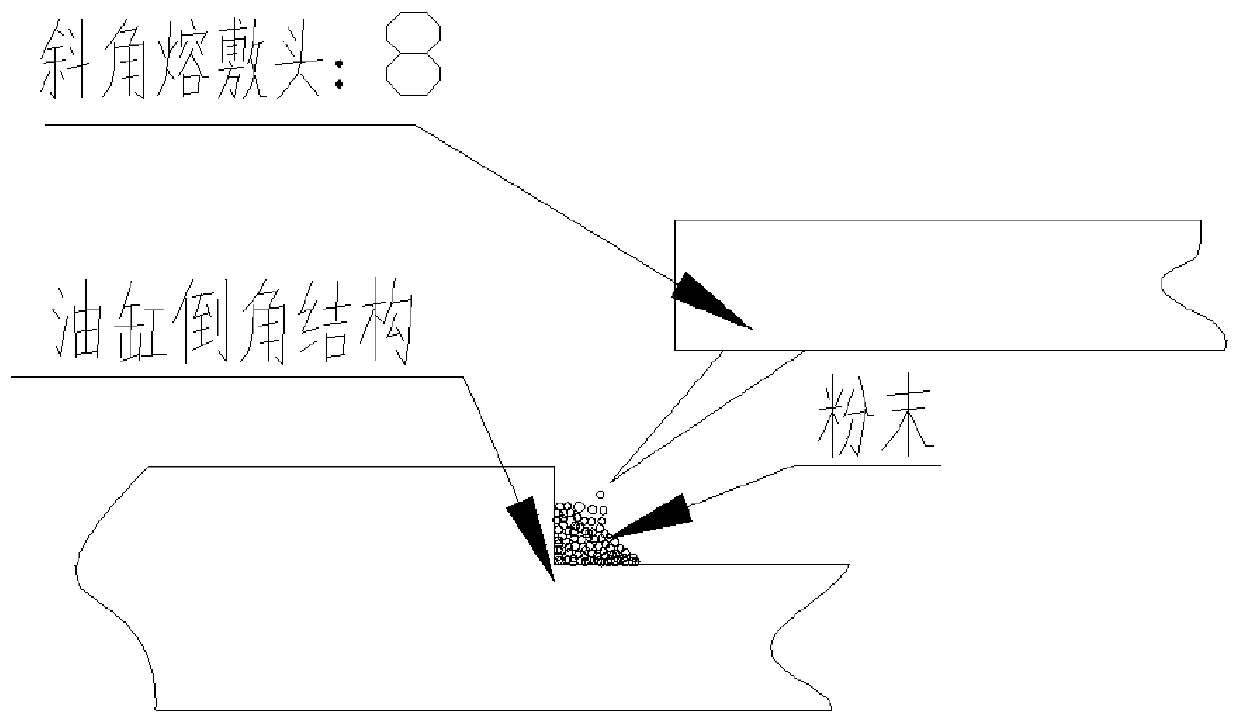

[0055] In this embodiment 1, the laser cladding of the present invention is performed on the inner wall of the 400 type waste hydraulic support oil cylinder (hereinafter referred to as 400 outer cylinder). The material of the oil cylinder outer cylinder is 27SiMn, as shown in the attached figure 1As shown, the inner diameter of the first area 1, the second area 2 and the third area 3 of the inner wall of the cylinder is 400 mm, the inner diameter of the fourth area 4, the fifth area 5 and the sixth area 6 is 420 mm, and the overall depth of the inner hole is 1900 mm. After measurement and calculation, the first area 1 is the bottom corner area with a length of 50mm and an area of 0.0628㎡; the second area 2 is an inner wall area with a length of 1550mm and an area of 1.9468㎡; the third area 3 and the sixth area 6 As the chamfering structure area, both are chamfering struct...

Embodiment 2

[0073] Below in conjunction with embodiment 2, the present invention is described in further detail.

[0074] In Example 2, laser cladding is carried out on the inner wall of the middle cylinder of the 300-type brand-new hydraulic support cylinder (hereinafter referred to as the 300 middle cylinder) by adopting the solution of the present invention. The material of the middle cylinder is 27SiMn, and the mechanical structure is as attached figure 1 As shown, the inner diameter of the first zone 1, the second zone 2 and the third zone 3 of the cylinder inner wall of the oil cylinder is 300mm, the inner diameter of the fourth zone 4, the fifth zone 5 and the sixth zone 6 is 320mm, and the total inner hole of the middle cylinder Depth 1900mm. After measurement and calculation, the first area, as the bottom corner, has a length of 50mm and an area of 0.0471㎡; the second area 2 is an inner wall area with a length of 1550mm and an area of 1.4601㎡; the third area 3 and the sixth a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com