Continuous cyclic powder spreading structure and additive manufacturing molding equipment

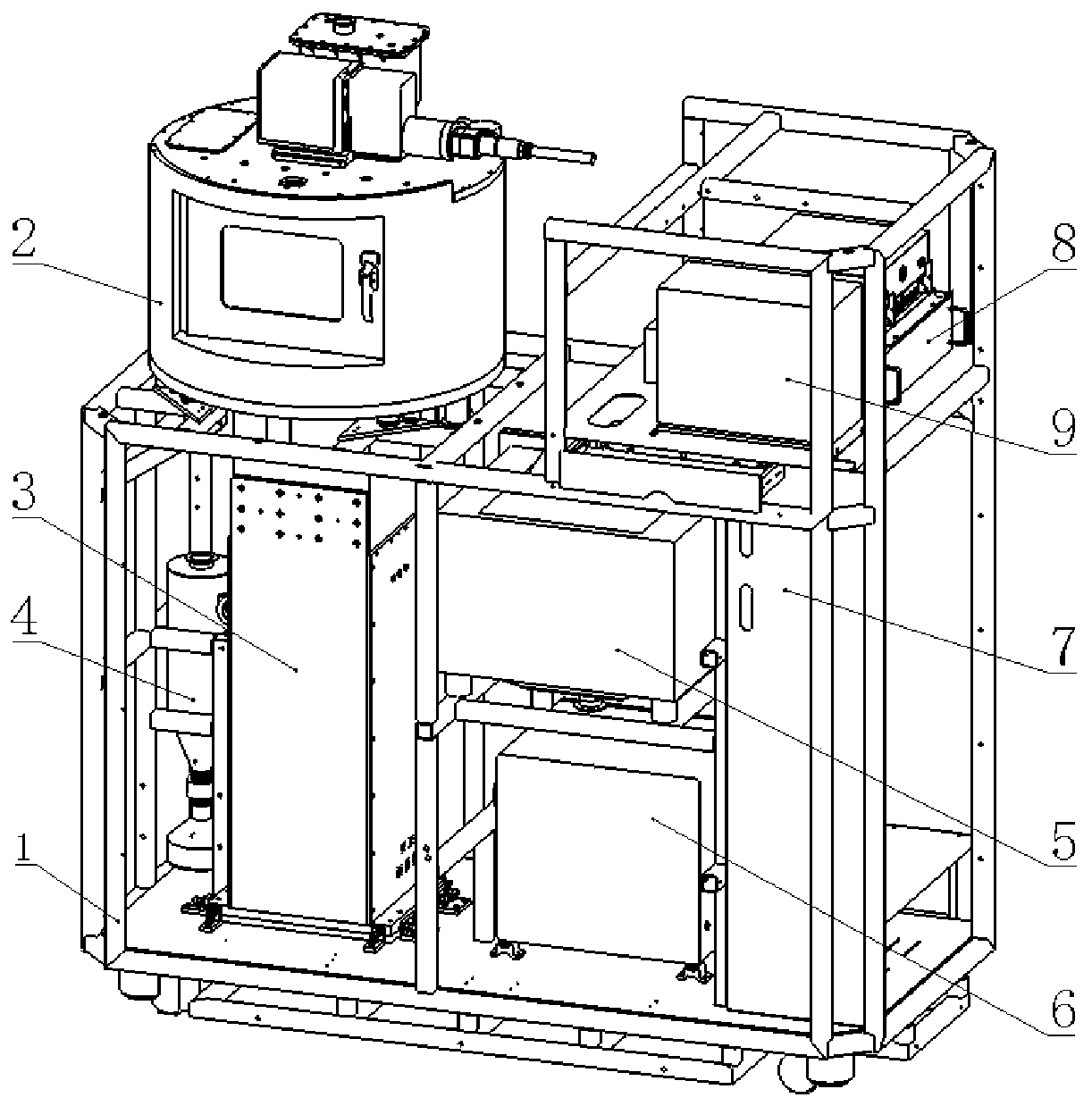

A technology of additive manufacturing and powder spreading, which is applied in the field of continuous circulating powder spreading structure and additive manufacturing forming equipment, can solve the problems of powder spreading and scanning, so as to improve the powder utilization rate, ensure the printing effect, and improve the forming efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described in further detail below in conjunction with accompanying drawing:

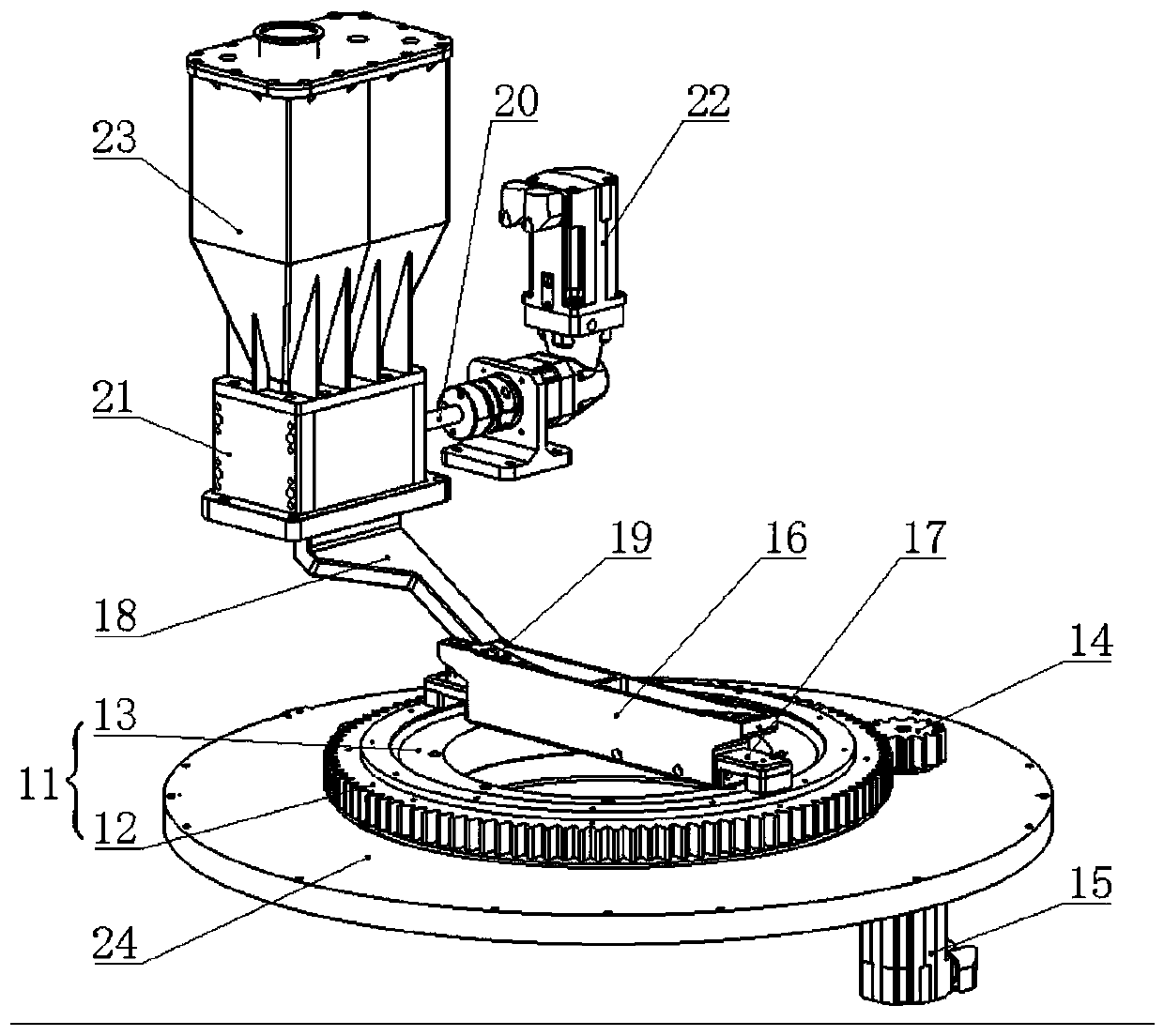

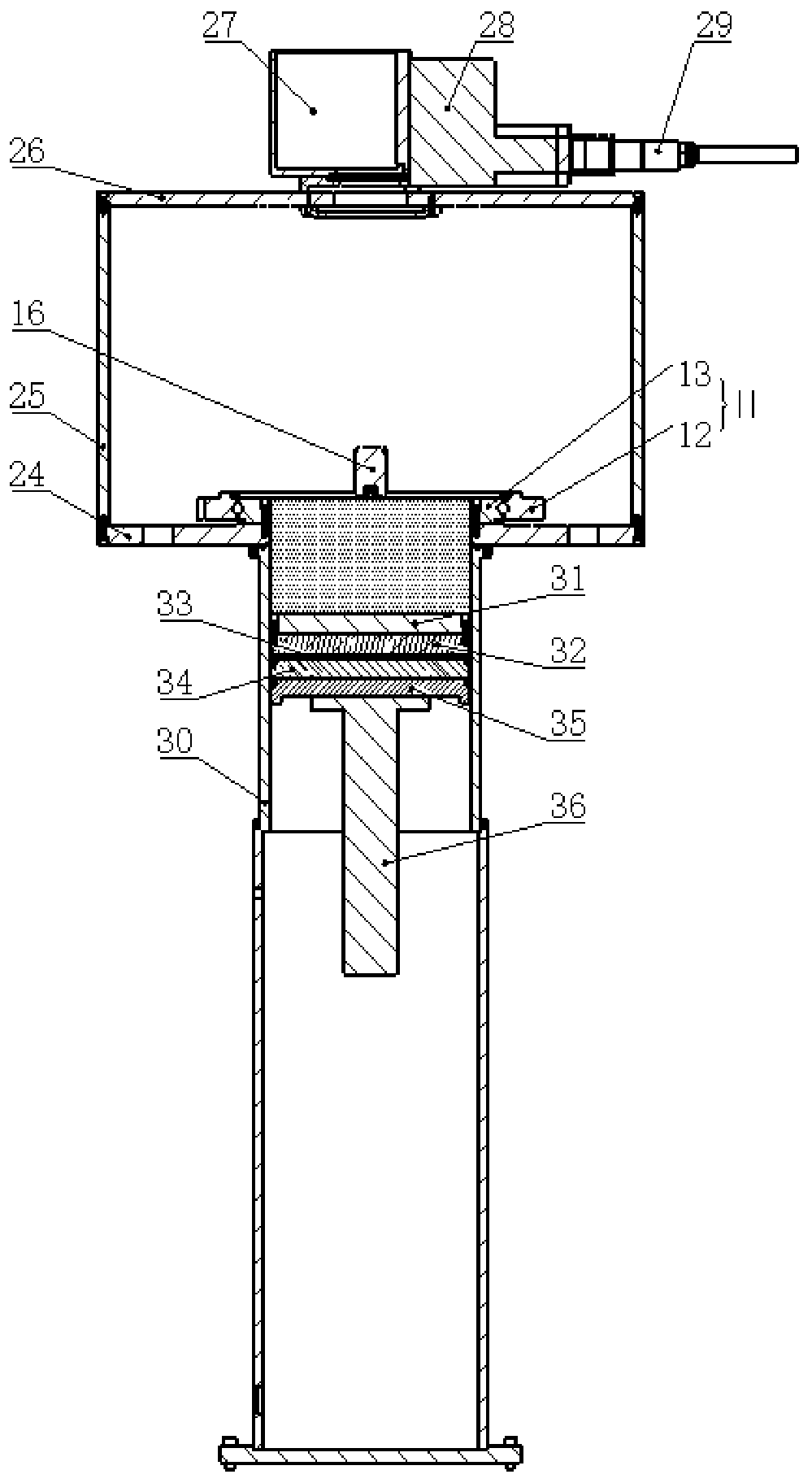

[0031] Such as Figure 2 to Figure 6 As shown, a continuous circulation powder spreading structure includes a powder spreading scraper 16, a gear bearing 11 and a platen 24, and a forming through hole is provided in the middle of the gear bearing 11 and the platen 24, and the gear bearing 11 includes an outer ring 12 and a nested The inner ring 13 that can rotate relative to the outer ring in the outer ring 12, the inner ring 13 is fixed on the upper end of the table 24, the powder spreading scraper 16 is fixed on the upper end of the outer ring 12, the outer ring 12 is provided with transmission teeth in the circumferential direction, and the table 24 is equipped with The printing substrate 31 formed on the part; the upper end of the powder spreading scraper 16 is provided with a buffer powder bin, and the buffer powder bin is provided with a deflector 19, and the def...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com