Forming cylinder for powder spreading type additive manufacturing equipment and in-cylinder piston body section adjusting method

A technology of additive manufacturing and forming cylinders, applied in the field of additive manufacturing, can solve the problems of expensive metal powder, waste of powder, waste of powder spreading, etc., maximize the usable forming area, improve the utilization rate of powder, and avoid waste of powder spreading Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

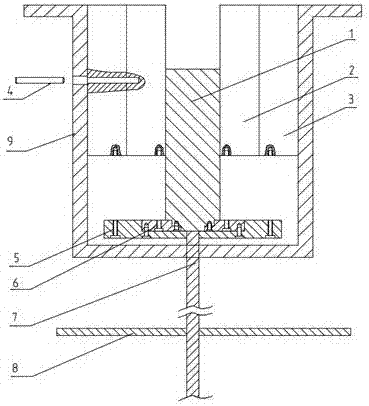

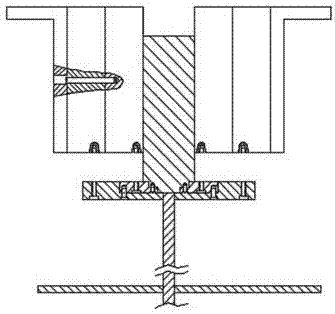

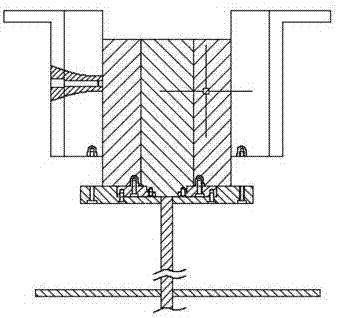

[0025] refer to figure 1 As shown, a method and device for improving the powder utilization rate of powder-spreading additive manufacturing equipment according to the present invention, in the embodiment, the device includes a piston body 1, a piston body 2 and a piston body 3, and the piston bodies 1, 2, 3 are all placed inside the forming cylinder body 9, the electric cylinder is connected with the bottom plate 8 through screws, and the telescopic rod 7 of the electric cylinder acts on the piston body 1 through the central hole of the bottom plate, so that the piston body 1 can always follow the telescopic rod of the electric cylinder for operation. Up and down telescopic movement, the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com