Method and its device for preparing cutter by laser coating composite ceramic layer

A technology of laser coating and composite ceramics, which is applied in the field of ceramic materials and ceramic coatings on metal surfaces, can solve the problems of large tool consumption, high tool cost, and high price, and achieve high production efficiency, improved service life, and coating good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

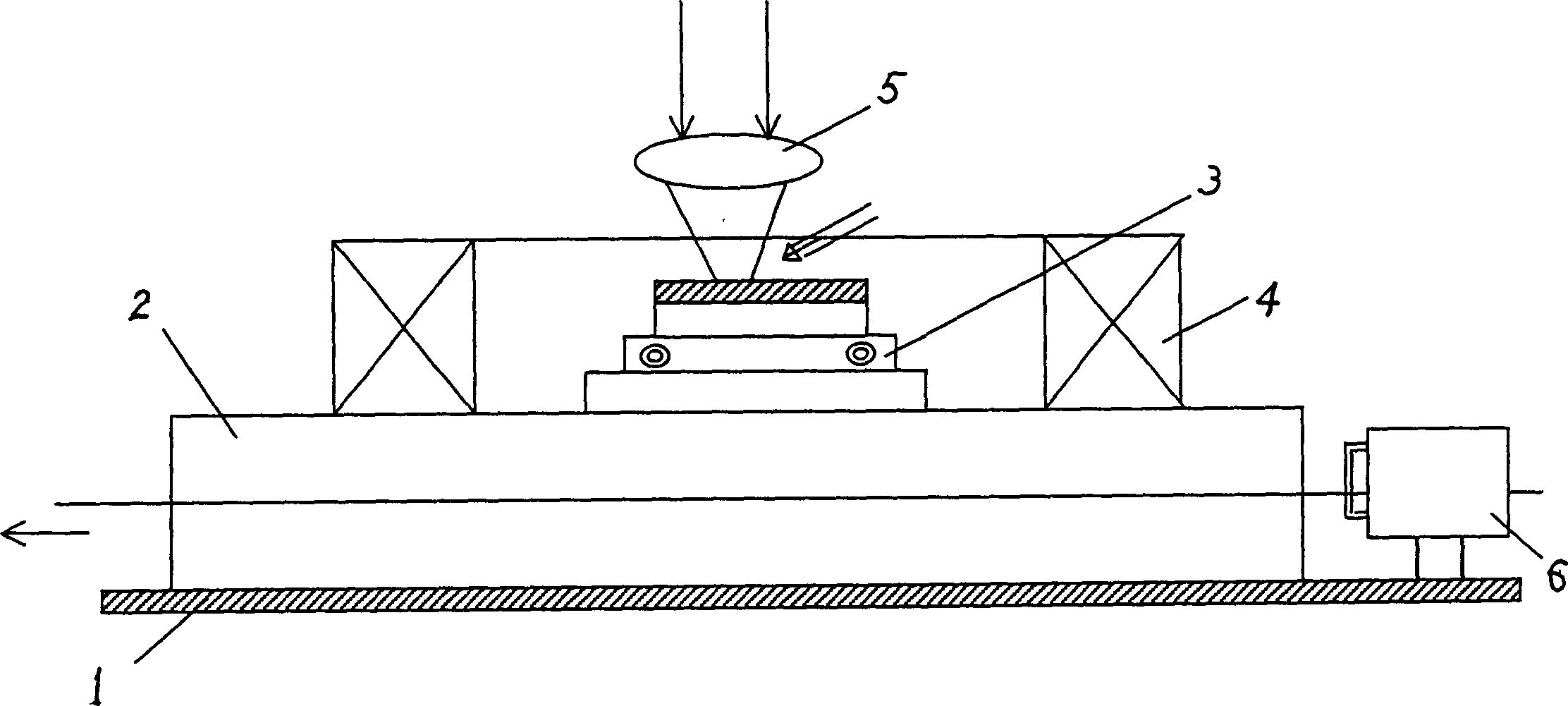

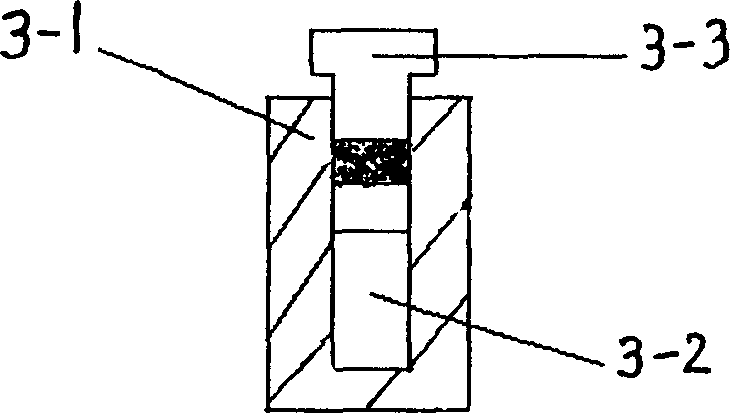

[0026] figure 1 It is a schematic diagram of the chemical fiber cutting knife laser coating device provided by the present invention. On the base 1, a workbench 2 and a special fixture 3 for presetting powder placed on the workbench 2 are installed. Electromagnetic coils 4 are arranged on both sides of the special fixture 3. Above the special fixture 3 is the laser processing system 5, the workbench 2 is driven by the motor 6 to move in the X direction, and the preset powder special fixture 3 is as figure 2 As shown, it is made up of concave groove 3-1, cushion block 3-2 and wedge-shaped briquetting block 3-3.

[0027] Use 2-3kw cross-flow continuous CO 2 Laser, the laser wavelength is 10.6μm, and the beam mode is multimode. Cobalt-based WC alloy powder with more than 200 meshes is selected, and 25% Tic, 8% Tac, 1% Al are added 2 o 3 , 1% SiO 2 , 0.05%Y 2 o 3 and 1% Al powder, etc., and the mixed powder is ball milled by a ball mill to make the powder mix evenly.

[00...

Embodiment 2

[0038] Choose 100-150 mesh cobalt-based tungsten carbide and 20% Tic, 8% Tac, 2% Al 2 o 3 , 0.5% SiO 2 , 0.1%Y 2 o 3 Mixed powder composed of carbide, oxide and 0.5% Al.

[0039] The laser coating composite ceramic coating prepares the cutting tool and adopts the method of laser coating while feeding powder, and its method does not add electromagnetic stirring, and the rest of the process is the same as in Example 1, and its process parameters are:

[0040] Laser beam power: 1.6-1.8kw

[0041] Laser beam spot diameter: 2.0-2.5mm

[0042] Scanning speed: 8-12mm / s

[0043] Shielding gas: Ar

[0044] Laser coating thickness: 0.8-1.0mm

Embodiment 3

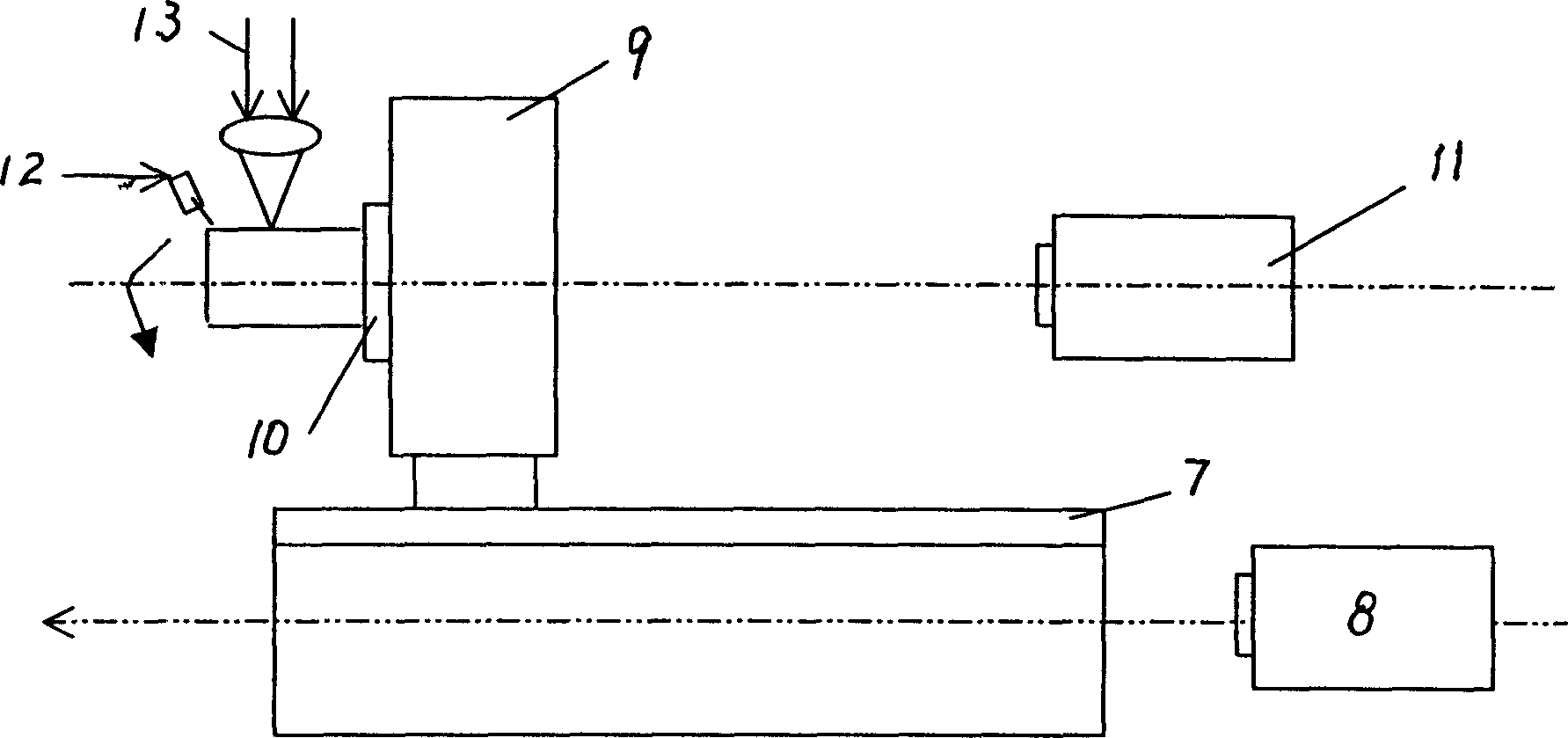

[0046] Laser coated 9CrSi material is used to prepare milling cutter blades. For the specific laser coating device for milling cutter blades, see image 3, which includes a workbench 7, a chuck device placed on the workbench, a chuck motor 11 on one side of the chuck device, an air powder feeder 12 located on the other side of the chuck device, and a laser processing system 13, the chuck The device consists of an indexer 9 and a three-jaw chuck 10. The laser processing system is located above the chuck device and the air powder feeder 12. The workbench 7 is driven by the workbench motor 8 to move in translation in the X direction.

[0047] The laser coating powder uses an inorganic resin (or organic) binder to adjust the mixed powder into a paste, and coats the powder on the helical blade of the milling cutter. See the attached figure. The laser coating process is as follows:

[0048] The laser beam is aimed at the pre-set powder of the milling cutter, and the milling cutter i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com